Coated airbag base fabric and airbag

A technology of airbags and base fabrics, which can be used in pedestrian/passenger safety arrangements, fabrics, vehicle safety arrangements, etc., and can solve problems such as air barrier properties and insufficient storage compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

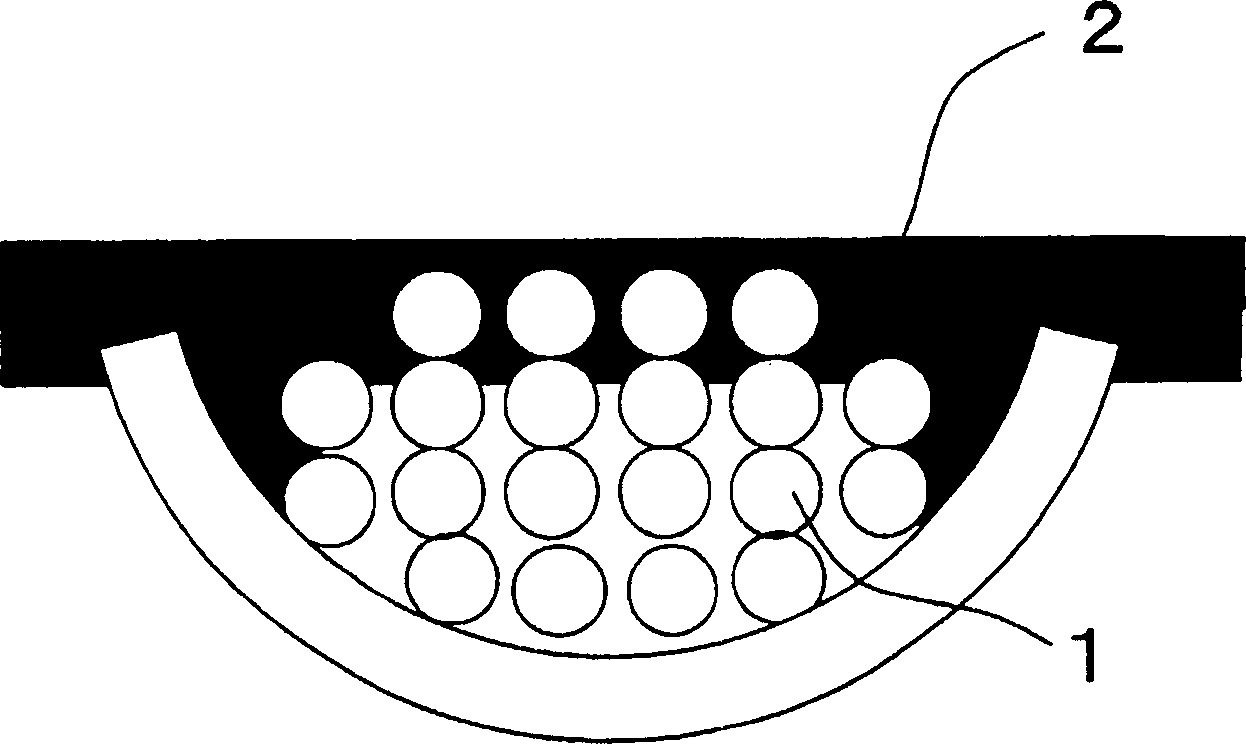

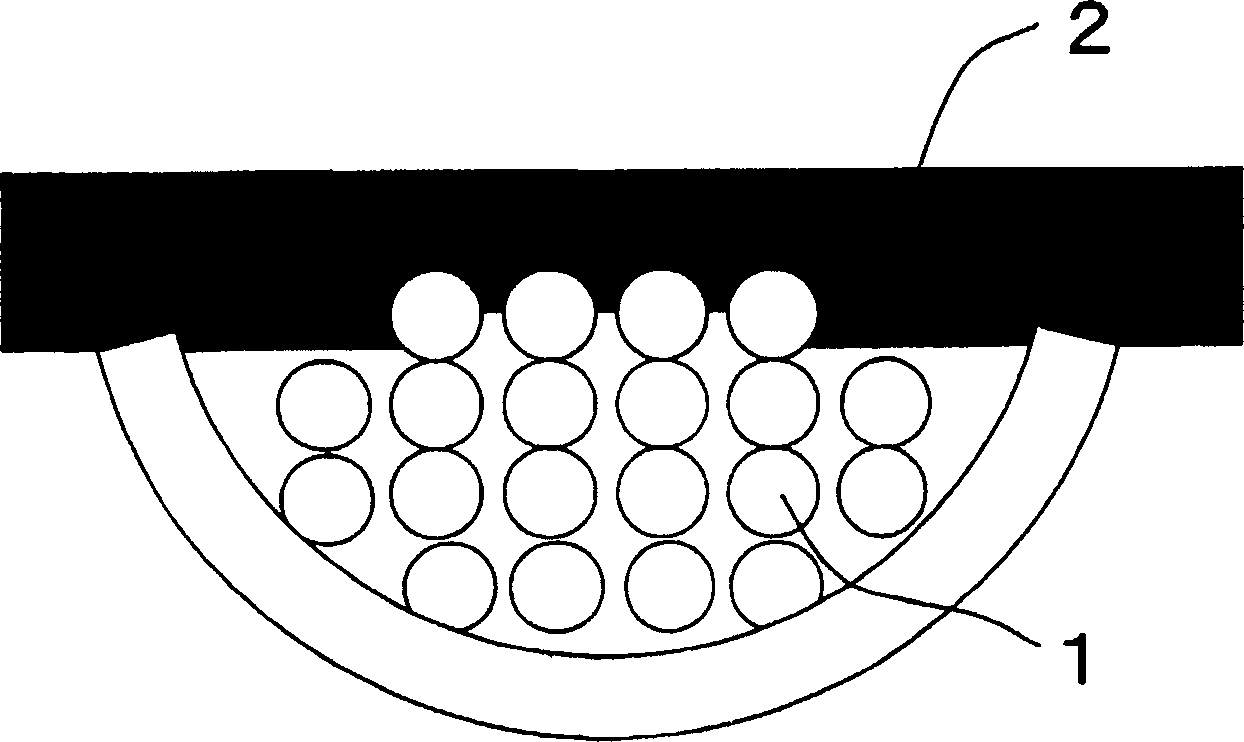

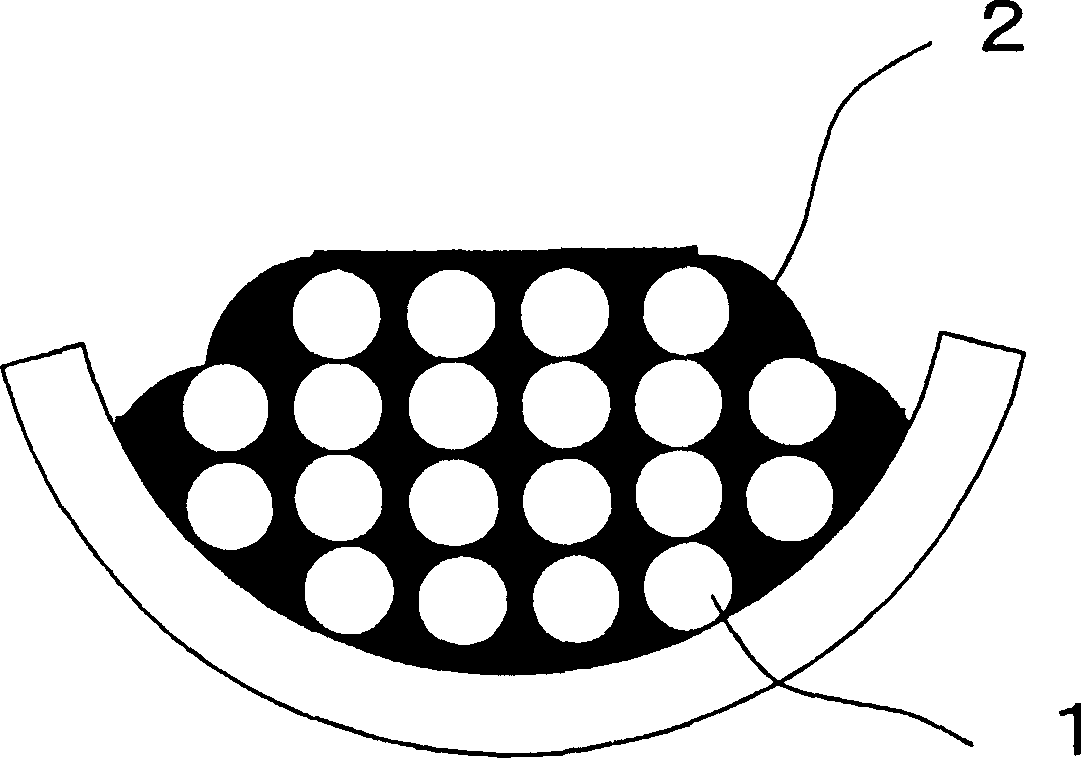

Method used

Image

Examples

Embodiment 1

[0077] Use a round cross-section filament with a total fineness of 470dtex, 72 monofilaments, a strength of 8.4cN / dtex, an elongation of 22%, an aspect ratio of 1.0, and untwisted nylon 6·6 fibers, and set the warp tension with a water jet loom It is 70cN / thread, and the weave density of warp thread and weft thread is adjusted to 46 threads / 2.54cm, obtains the fabric of plain weave. Then use a slate blade to apply a solvent-free methyl vinyl siloxane resin solution with a viscosity of 12 Pa·S (12,000 cP) to the fabric by a floating blade coating method, so that the contact pressure between the fabric and the slate blade is maintained at 9N / cm, resin adhesion is 15g / m 2 , and then vulcanized at 190° C. for 2 minutes to obtain a coated airbag base fabric.

[0078] Table 1 shows the properties of the airbag base fabric obtained above. The airbag base fabric is excellent in gas barrier properties, compact bag accommodation, and flame retardancy, and is also excellent in resin ad...

Embodiment 2

[0086] Use a total fineness of 350dtex, 96 monofilaments, a strength of 8.4cN / dtex, an elongation of 22%, an aspect ratio of 3.0, and untwisted nylon 6·6 fiber flat cross-section filaments, and use a water jet loom to set the warp tension to 100cN / thread, the weaving density of warp thread and weft thread is all adjusted to 59 threads / 2.54cm, obtains the fabric of plain weave. Then use a slate scraper to coat the fabric with a viscosity of 8Pa·S (8,000cP) toluene-diluted methyl vinyl siloxane resin solution (resin solid part is 80%) by the floating knife coating method, so that the fabric and The contact pressure of the slate scraper is kept at 2N / cm, so that the resin adhesion is 20g / m 2 , and then dried at 130° C. for 1 minute, and vulcanized at 200° C. for 2 minutes to obtain a coated airbag base fabric.

[0087] Table 1 shows the properties of the airbag base fabric obtained above. The airbag base fabric is excellent in gas barrier properties, compact bag accommodation...

Embodiment 3

[0095] Use total fineness 235dtex, 72 monofilaments, strength 8.4cN / dtex, elongation 24%, aspect ratio 1.0, circular section filament of untwisted nylon 6 fiber, with air-jet loom, warp tension is set to 90cN / root, the weaving density of the warp and weft is adjusted to 76 / 2.54cm to obtain a plain weave fabric. The fabric was then soaked in an 80°C warm water bath containing 0.5 g / l sodium alkylbenzene sulfonate and 0.5 g / l soda ash for 3 minutes, then dried at 130°C for 2 minutes, followed by heat setting at 180°C for 1 minute. Then use the slate scraper to coat the heat-set fabric with a viscosity of 10 Pa·S (10,000 cP) water-based polyurethane resin solution (50% resin solid part) by floating blade coating method, and make the fabric and the slate scraper Keep the contact pressure at 6N / cm, so that the resin adhesion is 20g / m 2 , and then dried at 130° C. for 1 minute to obtain a coated airbag base fabric.

[0096] Table 1 shows the properties of the airbag base fabric o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adhesion amount | aaaaa | aaaaa |

| Adhesion amount | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap