Injection device

A technology of injection device and injection hole, which is applied in the field of plastic molding devices, can solve the problems of cost, shutdown replacement, cover damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

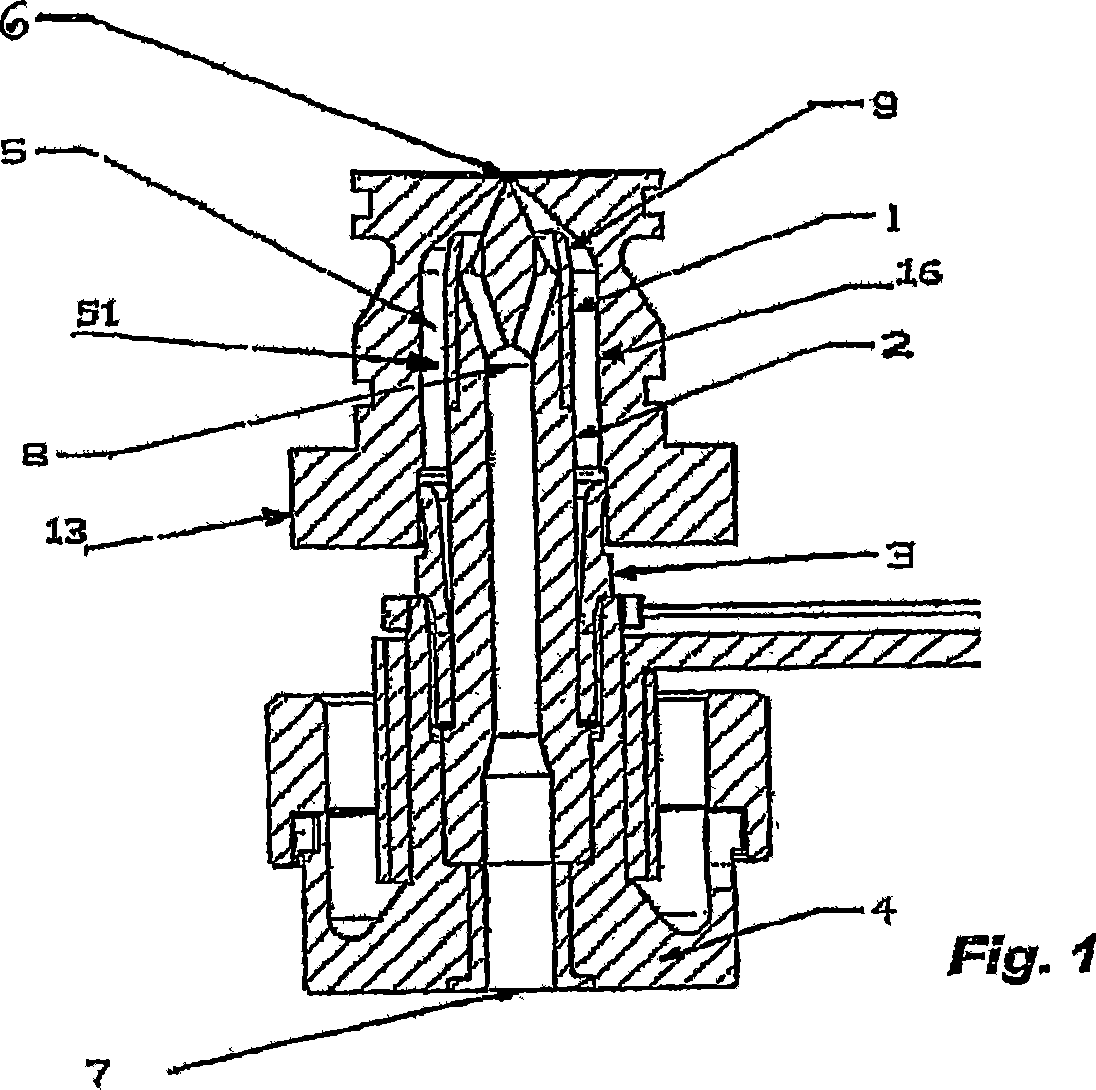

[0027] Fig. 1, Fig. 1A and Fig. 2 have described the first embodiment of a kind of injection device of the present invention, and in described embodiment, injection device comprises tip holder 4 and the heater that is fixed on it by centering ring nut 3 tip. The heating tip comprises a housing 2 in which a passage 8 is connected to the hot half of the plastic material molding mold through a suitable conduit. Reference numeral 7 indicates the end of the channel 8 on the side of the hot half.

[0028] Reference numeral 13 denotes a hollow mold closest to the molding cavity (not shown) of the mold.

[0029] The plastic material that flows out of the hot half of the mold during injection via the inner channel 8 flows out of the housing 2 through the outflow hole 14, is guided by the conical wall on the groove 16 of the mould, reaches the injection hole 6, and then reaches the injection hole 6 according to the design. The molding cavity where the molded object is finally shaped. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com