Crate for carrying glass panels

a glass panel and crate technology, applied in the direction of containers, tray containers, packaged goods, etc., can solve the problem of still being damaged during the transpor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

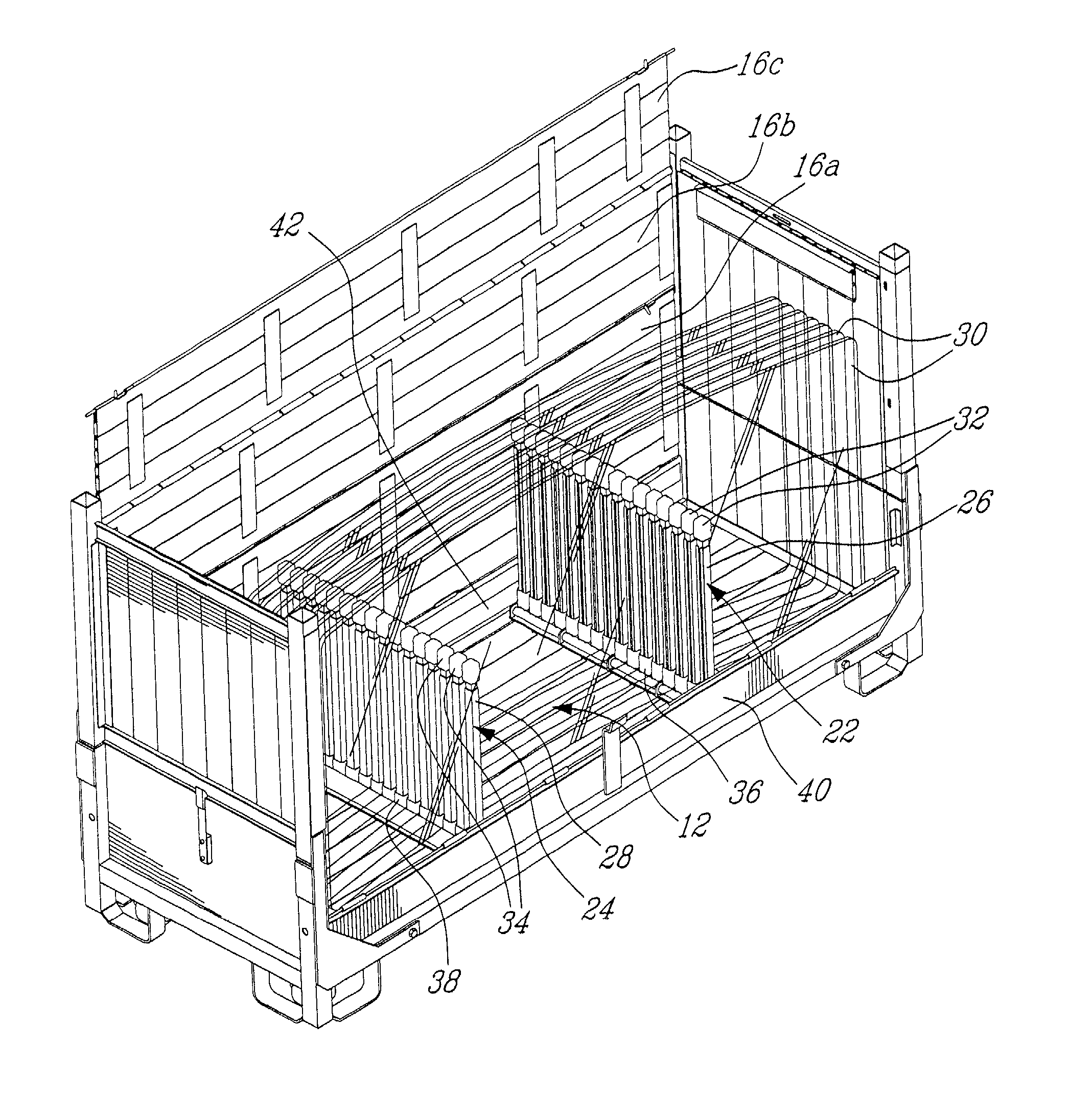

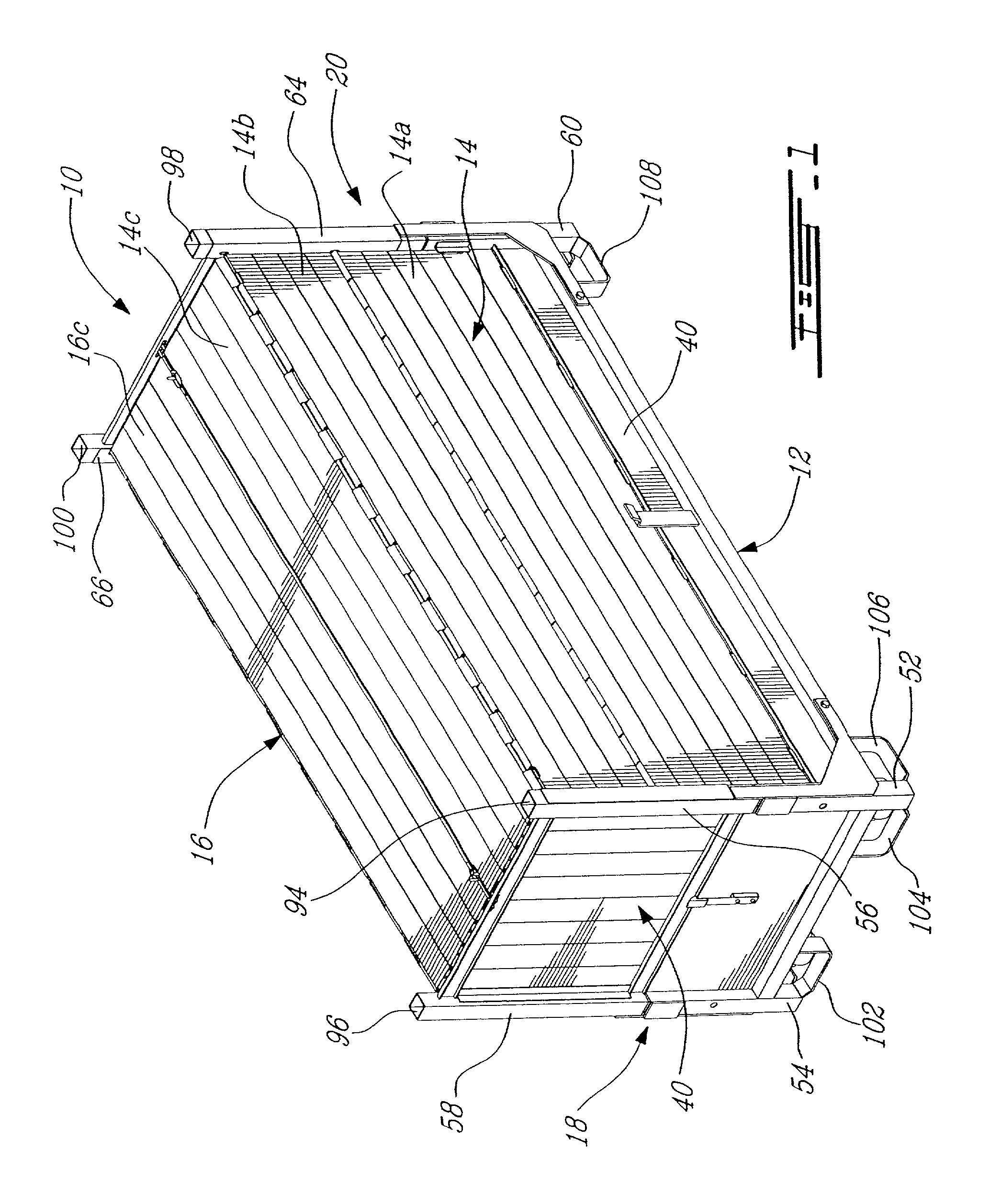

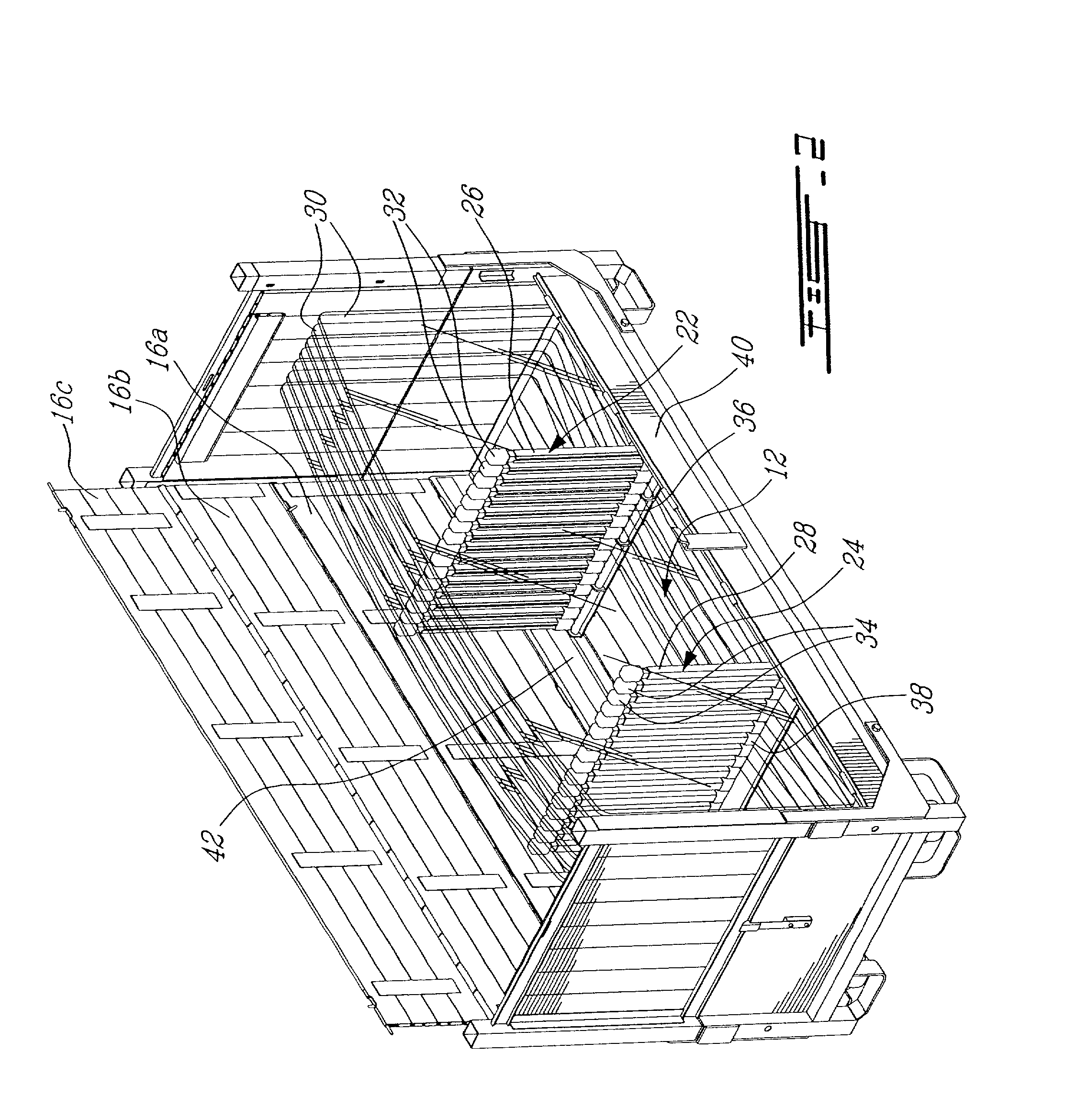

[0021] Referring to FIG. 1, there is shown a crate, generally denoted 10, which consists of a longitudinal body frame including a base 12, opposite side panels 14 and 16 and opposite end panels 18 and 20.

[0022] Referring also to FIG. 2 where side panel 14 has been omitted for illustration purposes, the base 12 displays a pair of longitudinally spaced comb-like supports 22 and 24, each consisting of a series of vertical posts 26, 28 which are laterally spaced from one another in order to receive a series of glass panes 30 having a given size and curvature and extending in the longitudinal direction of the frame. The top of the posts 26, 28 are capped with pads 32, 34 to contact and protect the windshields 30. The lower ends of the posts 26, 28 are respectively mounted on a common horizontal member 36, 38 having its respective opposite ends pivotally mounted to a fixed base member 40, 42 so that the support assemblies may be moved from the vertical position shown to a horizontal posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com