Multiple casting apparatus and method

a technology of multiple casting and casting apparatus, applied in the direction of electrical equipment, cell electrodes, cell components, etc., can solve the problems of unfinished surface, parts to be rejected, battery parts that are not suitable for use, etc., and achieve the effect of avoiding localized surface penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

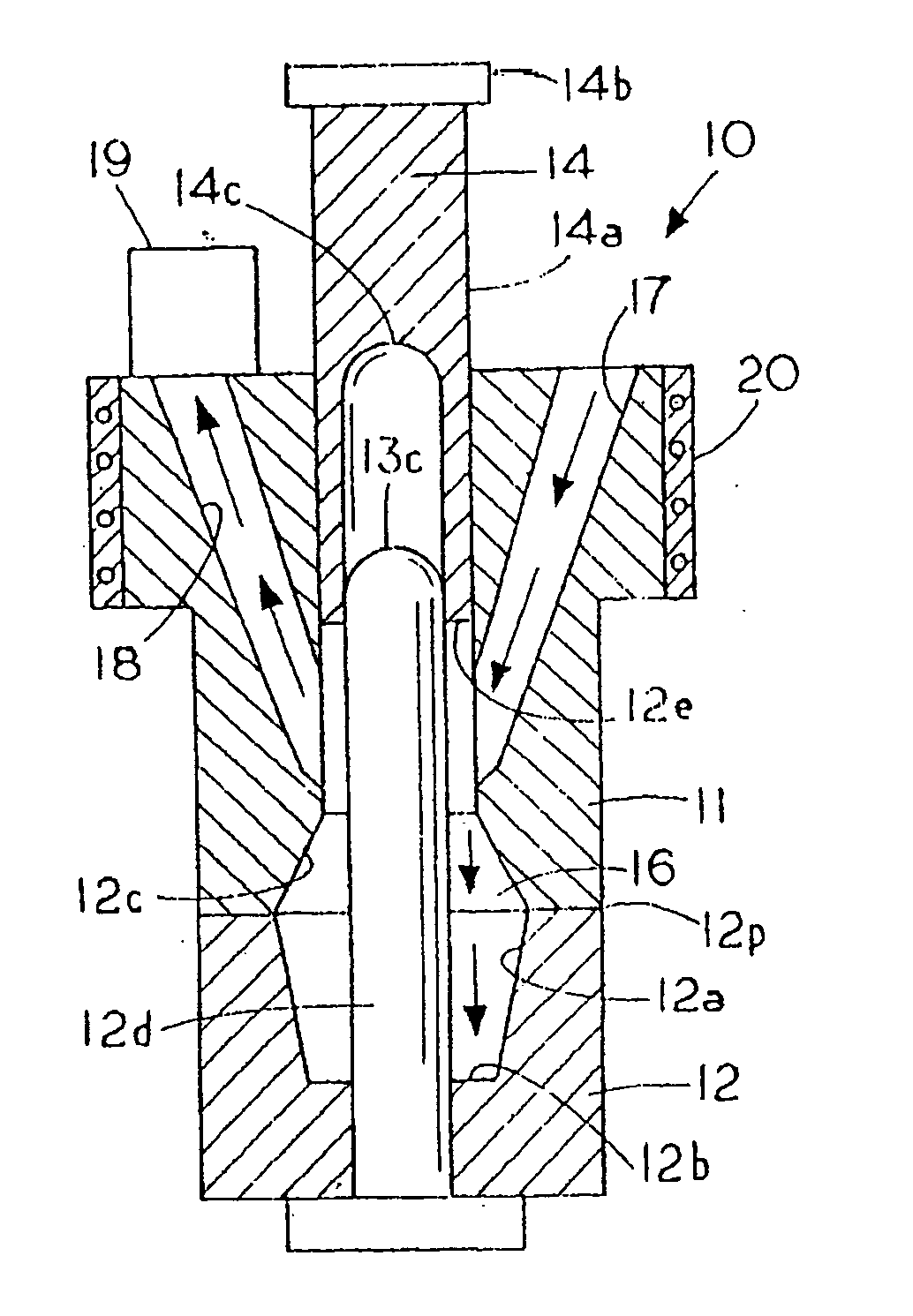

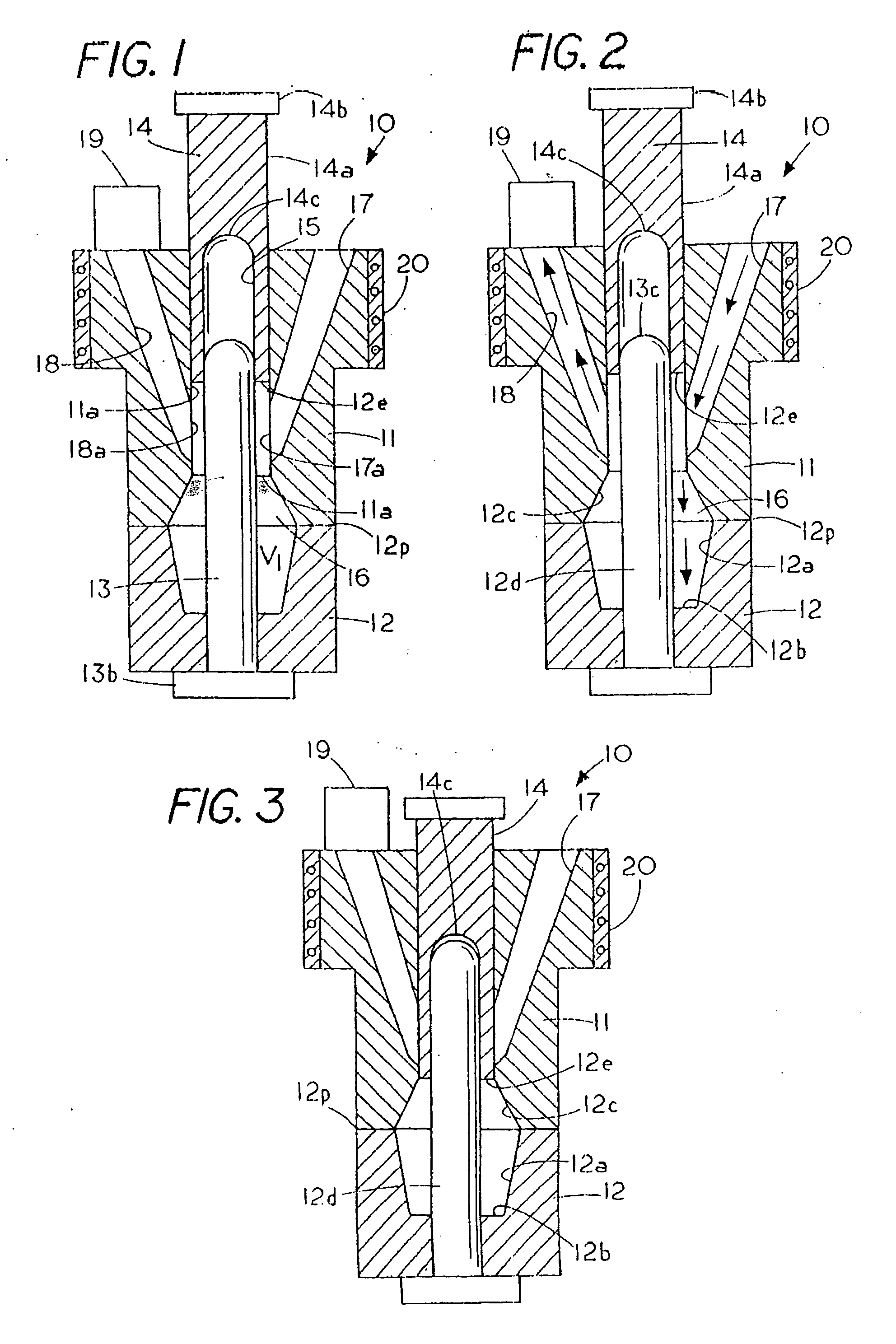

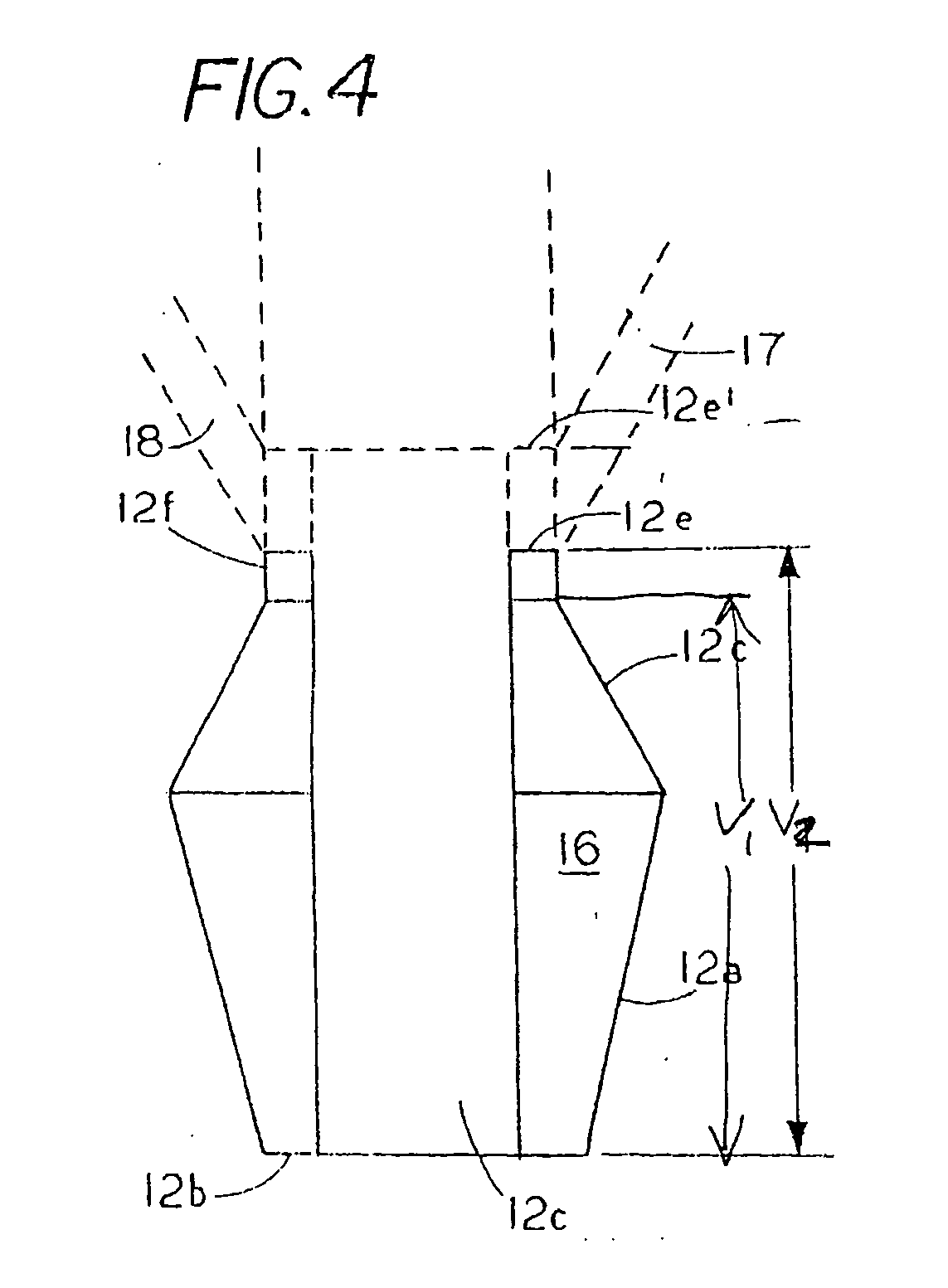

[0021]FIG. 1 is a partial sectional view of apparatus 10 for face intensification during die casting of battery parts. Apparatus 10 includes an upper first mold part 11 and a lower second mold part 12 that are held proximate each other by a member (not shown) to form a cavity 16 therein. The two parts are joined a parting surface 12p that extends between the two mold parts.

[0022] Located partially in mold part 11 is a first extendible cylindrical piston 14 which is axially slideable into mold part 11. Piston 14 includes a cylindrical surface 14a for slideingly engaging cylindrical surface 11a in mold part 11 to prevent molten lead from flowing therepast. The end of piston 14 includes a hemispherical recess 14c and an annular impact surface 12e there around with the annular impact surface 12e located in a single plane. Extendible piston 14 slidingly engages the sidewall 11a of mold part 11 to allow for axial insertion thereof to bring the impact surface 12e downward to become a port...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

| charge | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com