Storage bin assembly

a technology for storage bins and assemblies, which is applied in the field of storage bin assemblies for vehicles, can solve the problems of restricting the design tolerances of fore-aft overhead assemblies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

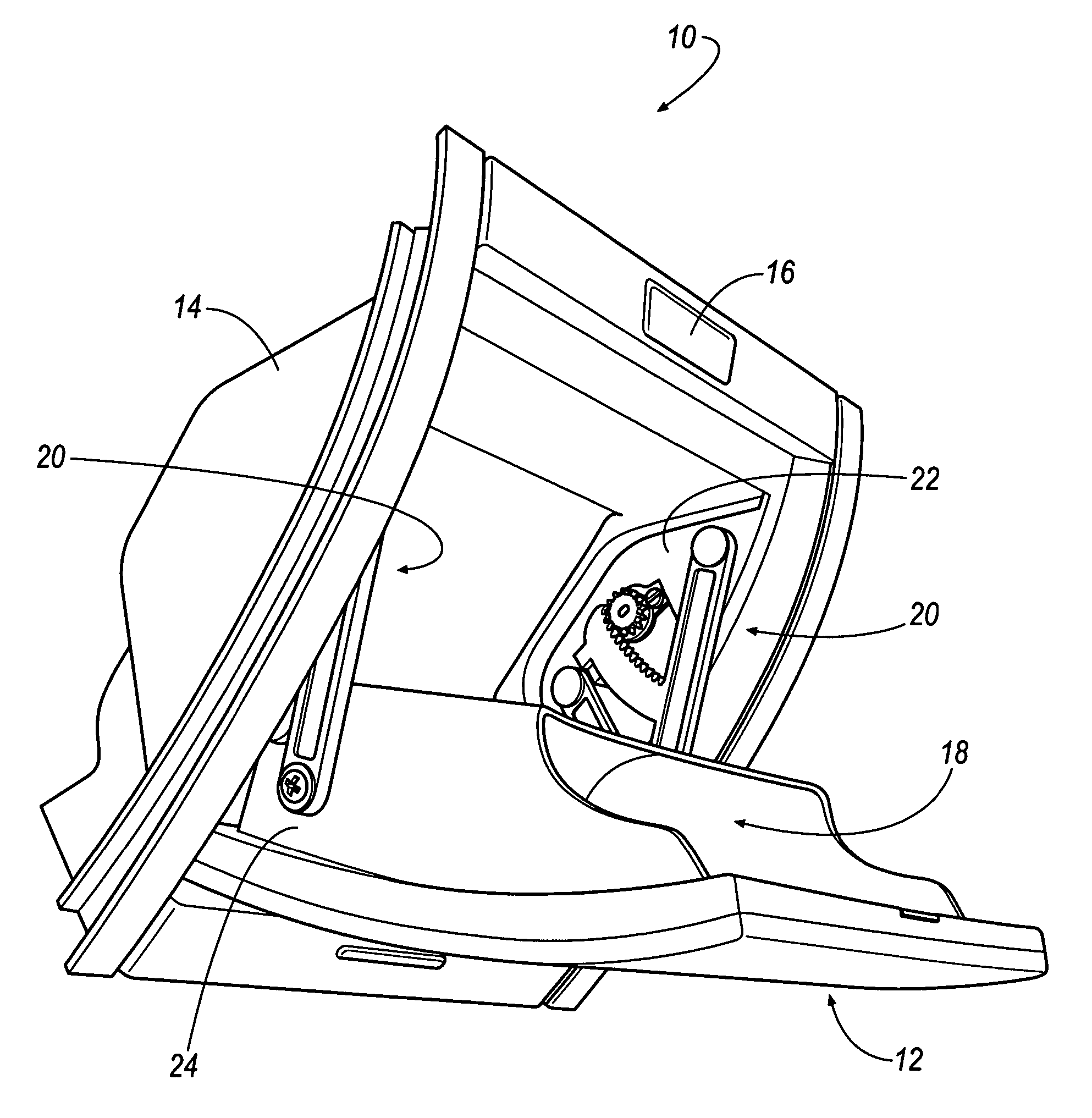

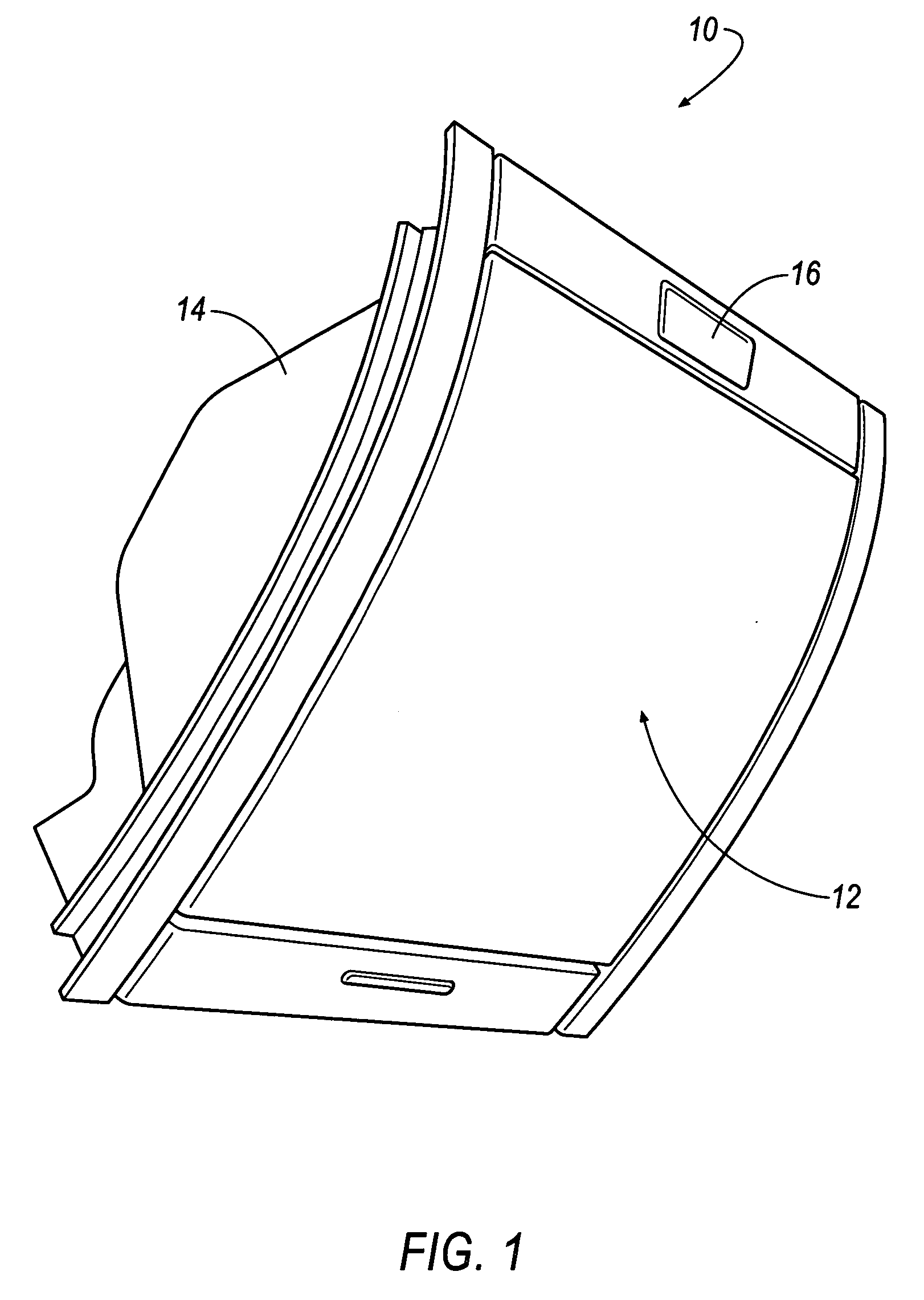

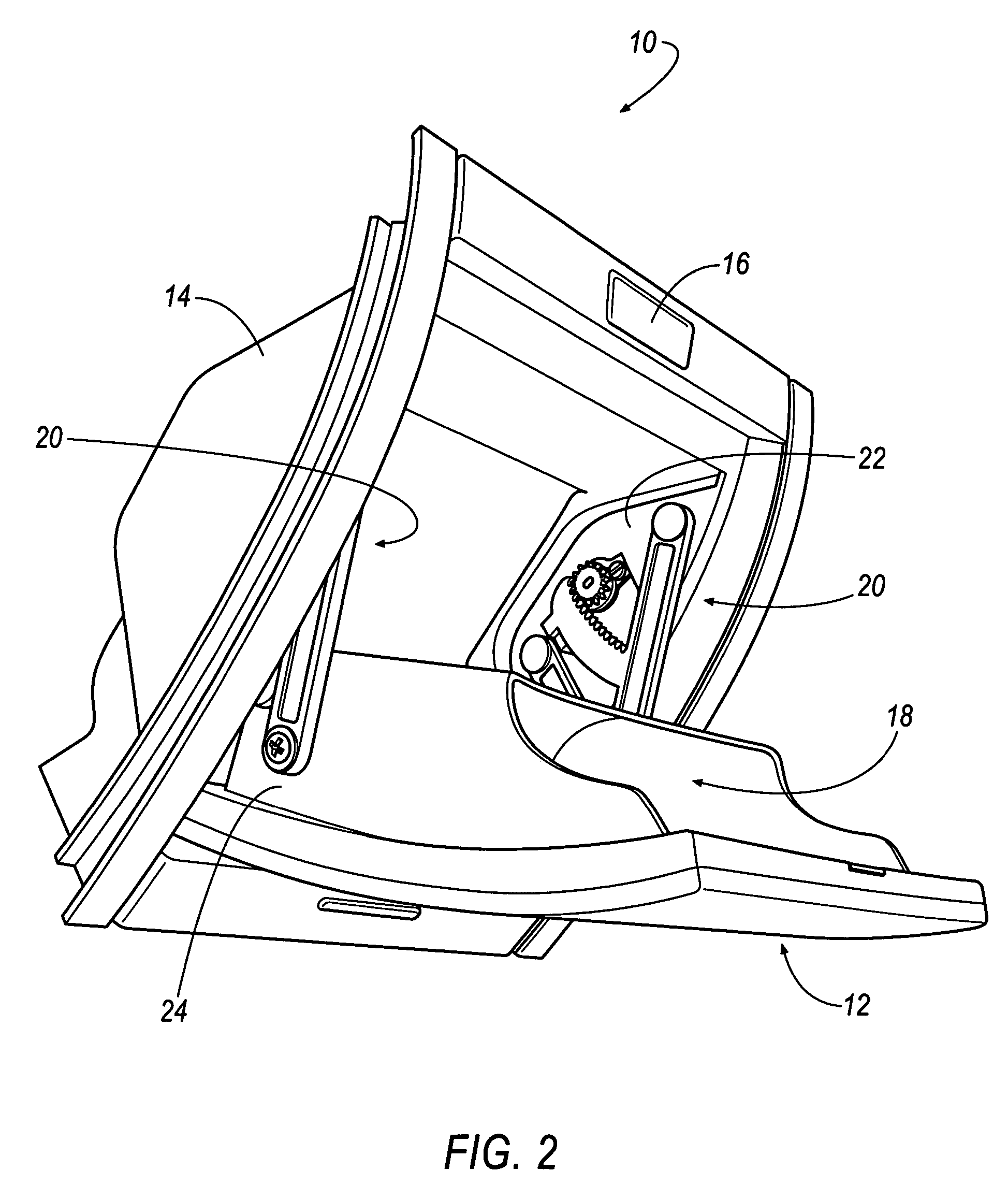

[0011] The above described disadvantages are overcome and a number of advantages are realized by an inventive storage bin assembly, which is seen generally at 10 in FIGS. 1 and 2. In general, the storage bin assembly 10 comprises a door 12 and an enclosure 14. If desired, a button 16 may be located on the storage bin assembly 10 at any desirable location to cause an un-latching or to initiate movement of the door 12 relative the enclosure 14. However, it will be appreciated that the design of the storage bin assembly 10 may not include the button 16 and that the door 12 may be initially moved relative the enclosure 14 with a conventional ‘push-push’ mechanism, or the like. Referring to FIG. 2, the door 12 is illustrated in a fully deployed position and includes an integral storage compartment 18 for stowing sunglasses, maps, and the like. The storage compartment 18 substantially occupies the entire volume of the enclosure 14 when the door 12 is in the stowed position.

[0012] In gene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com