Fire resistant mattress

a mattress and mattress technology, applied in the field of fire-resistant mattresses, can solve the problems of ineffective barrier against flame, poor flame prevention performance of slide fasteners and hook and pile fasteners, and a recognized problem of mattress fires

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

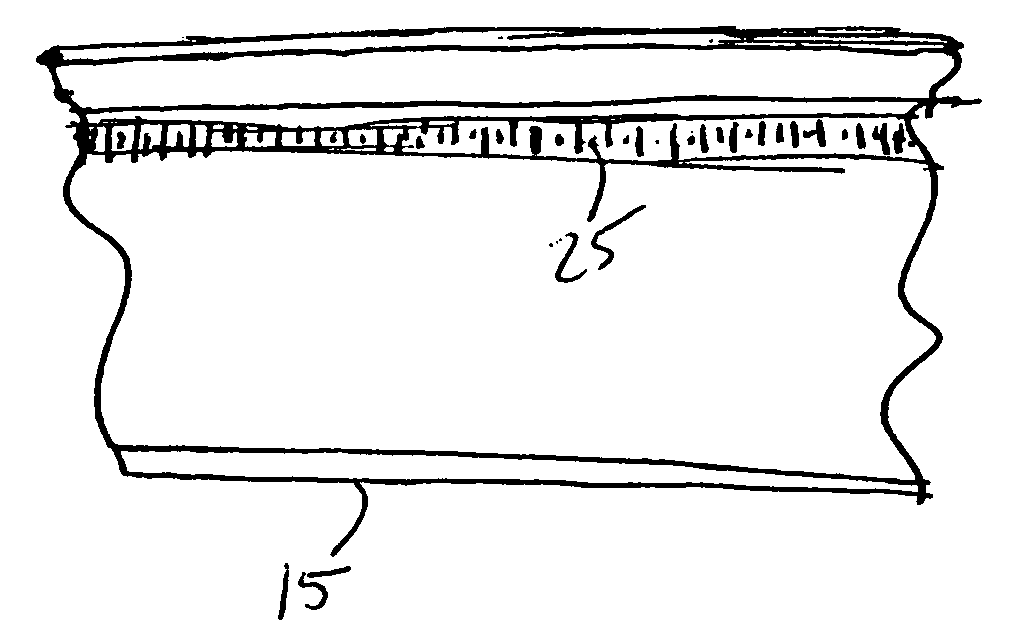

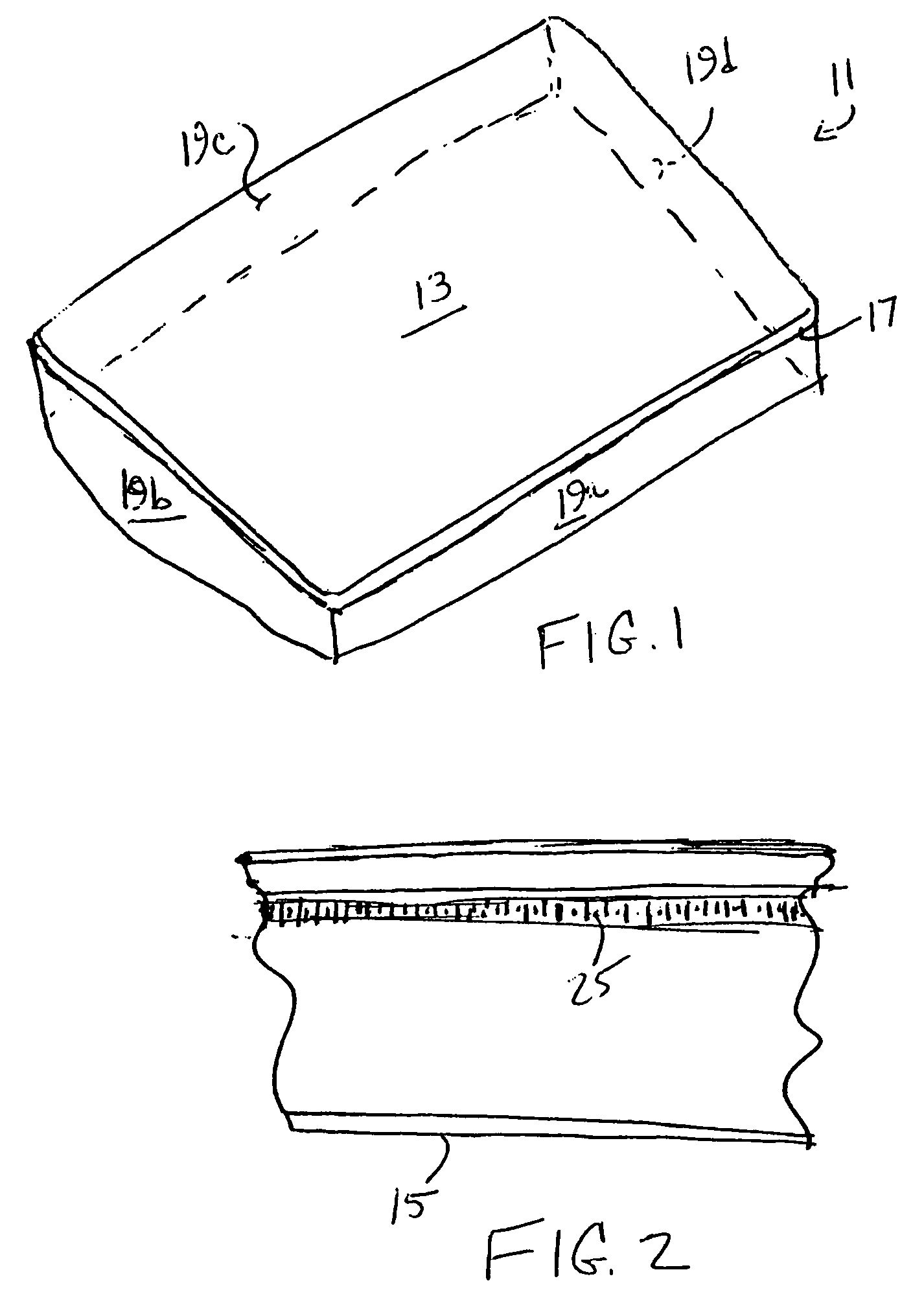

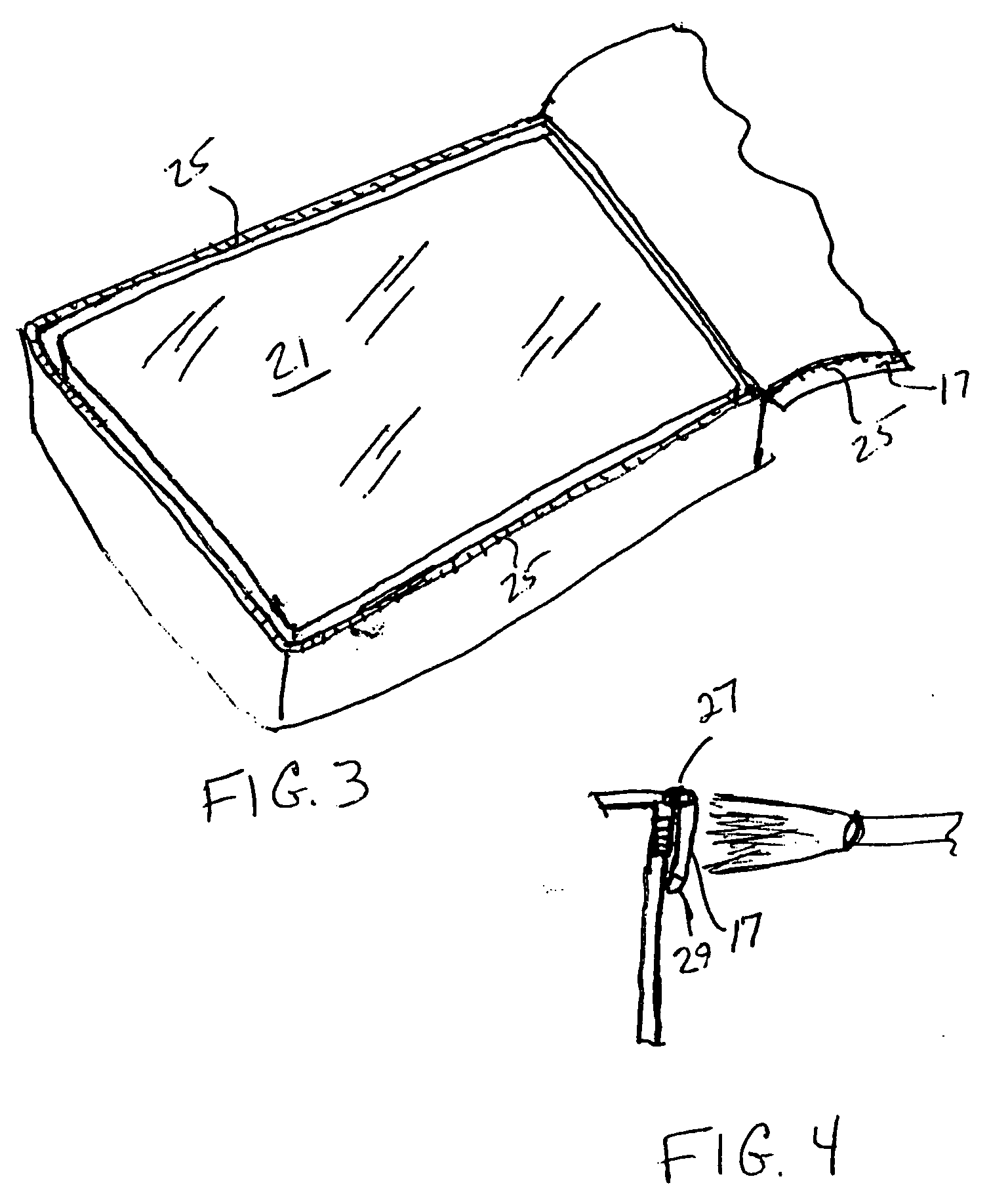

[0023] Turning to the drawings, a fire resistant mattress 11 of the present invention includes a top surface 13, a bottom surface 15 (FIG. 2), and a flap 17. Top surface 13 and bottom surface 15 are connected together by a side surface 19 which forms the various sides of the mattress. The mattress as shown has four sides 19a-19d, although mattresses of different shapes could have more or fewer sides. Together the top, bottom and side surfaces, along with flap 17, form a cover for the mattress which encloses a mattress core 21 (FIG. 3) having at least one combustible (flammable) component. Core 21 is shown in FIG. 3 as a solid foam core, but the present invention is not limited to such cores.

[0024] The top, bottom and side surfaces, as well as the flap, are composed of fire resistant material, which may be any of such materials known in the art. It is preferred that the cover made up of such surfaces may be removable so as to expose the core for cleaning, replacement, etc. To facili...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com