Door handle assembly

a door handle and assembly technology, applied in the field of door handles, can solve the problems of increasing the possibility of the door handle swinging open during an impact, increasing the manufacturing time and cost, and affecting the safety of the vehicle inside the door handl

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

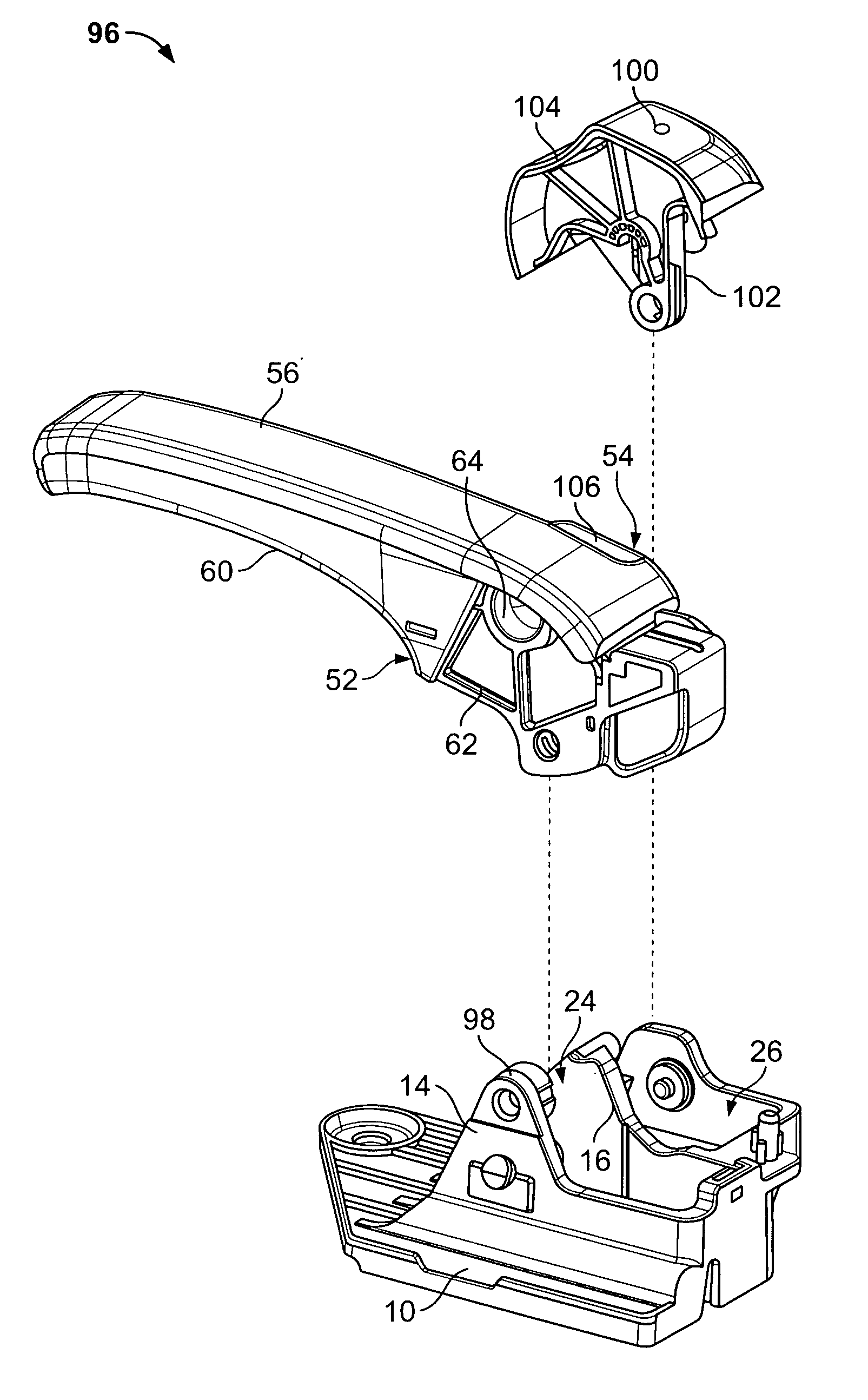

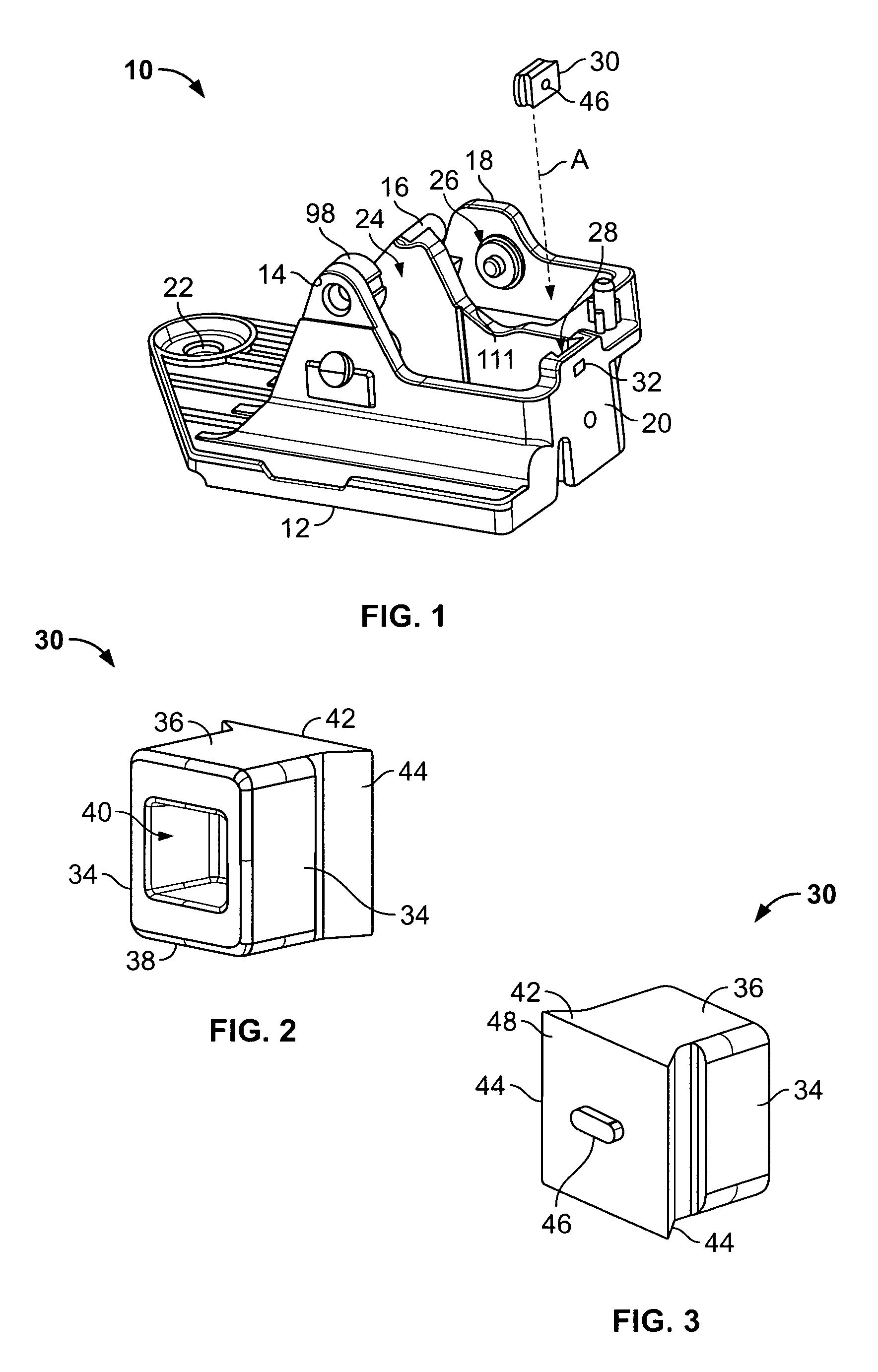

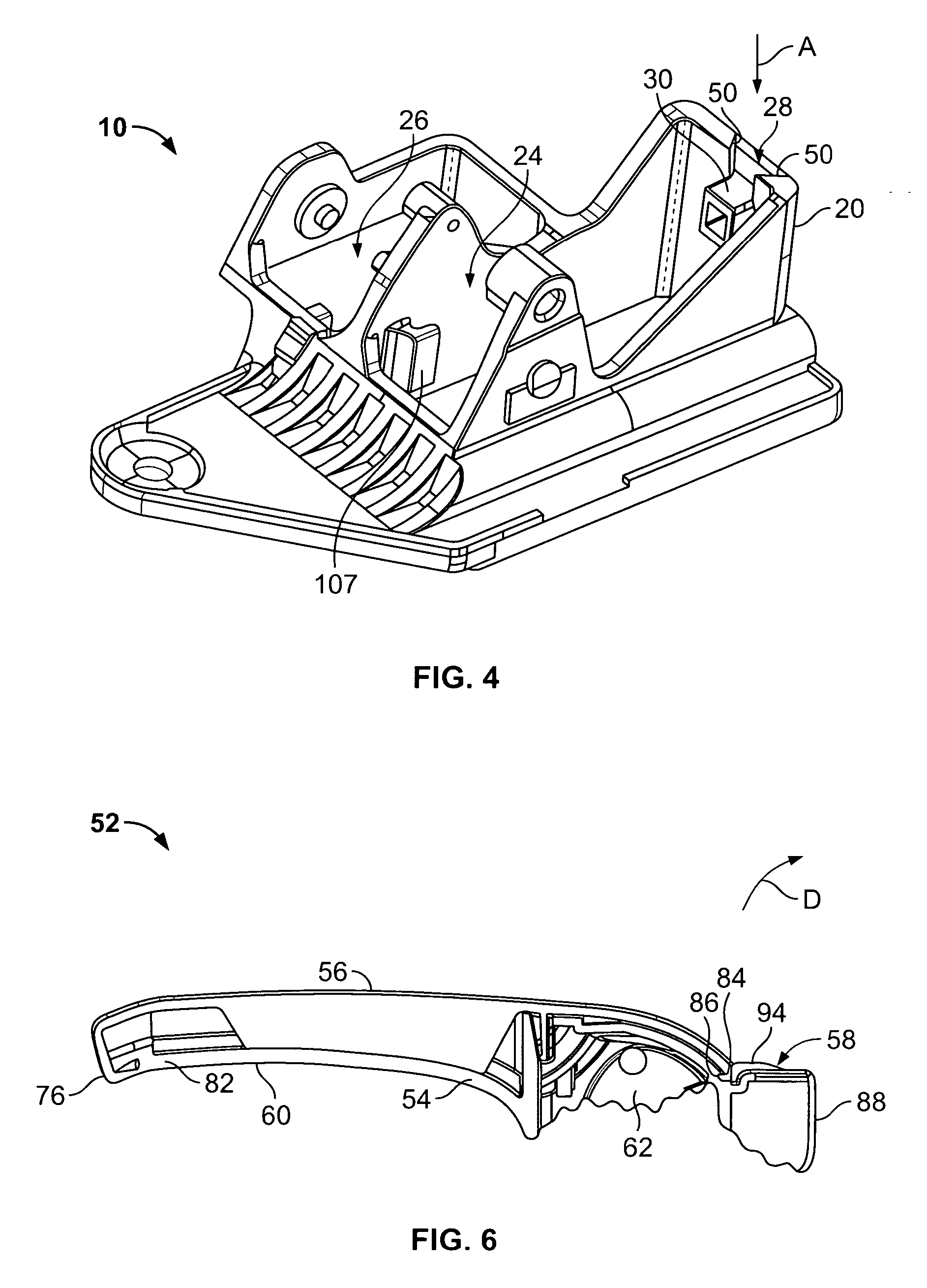

[0022]FIG. 1 illustrates an isometric rear view of a handle pivot housing 10 according to an embodiment of the present invention. The housing 10 includes a lower support wall 12 integrally formed with upstanding handle-engaging walls 14 and 16, an upstanding lock wall 18, and a rear, or bumper, wall 20. The lower support walls 12 includes a fastener through-hole 22 and other features that are configured to secure the handle base 10 to a fixed structure, such as an interior of a door. A handle pivot cavity 24 is defined between the two handle-engaging walls 14 and 16, while a lock knob cavity 26 is defined between the handle-engaging wall 16 and the lock wall 18. The rear wall 20 includes a channel 28 configured to receive and retain a bumper 30. A slot, opening or depression 32 is formed through the rear wall 20 and extends into the channel 28. The slot 32 is configured to snapably secure a reciprocal structure 46 on the bumper 28, which is urged into the channel in the direction of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Structure | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Shape | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com