Tool case

a tool and case technology, applied in the field of tools storage and storage devices, can solve the problems of lack of features which enhance utility, lack of structure, and lack of prior devices, and achieve the effects of reducing gravitational load, facilitating versatile storage capacity and tool display, and reducing structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

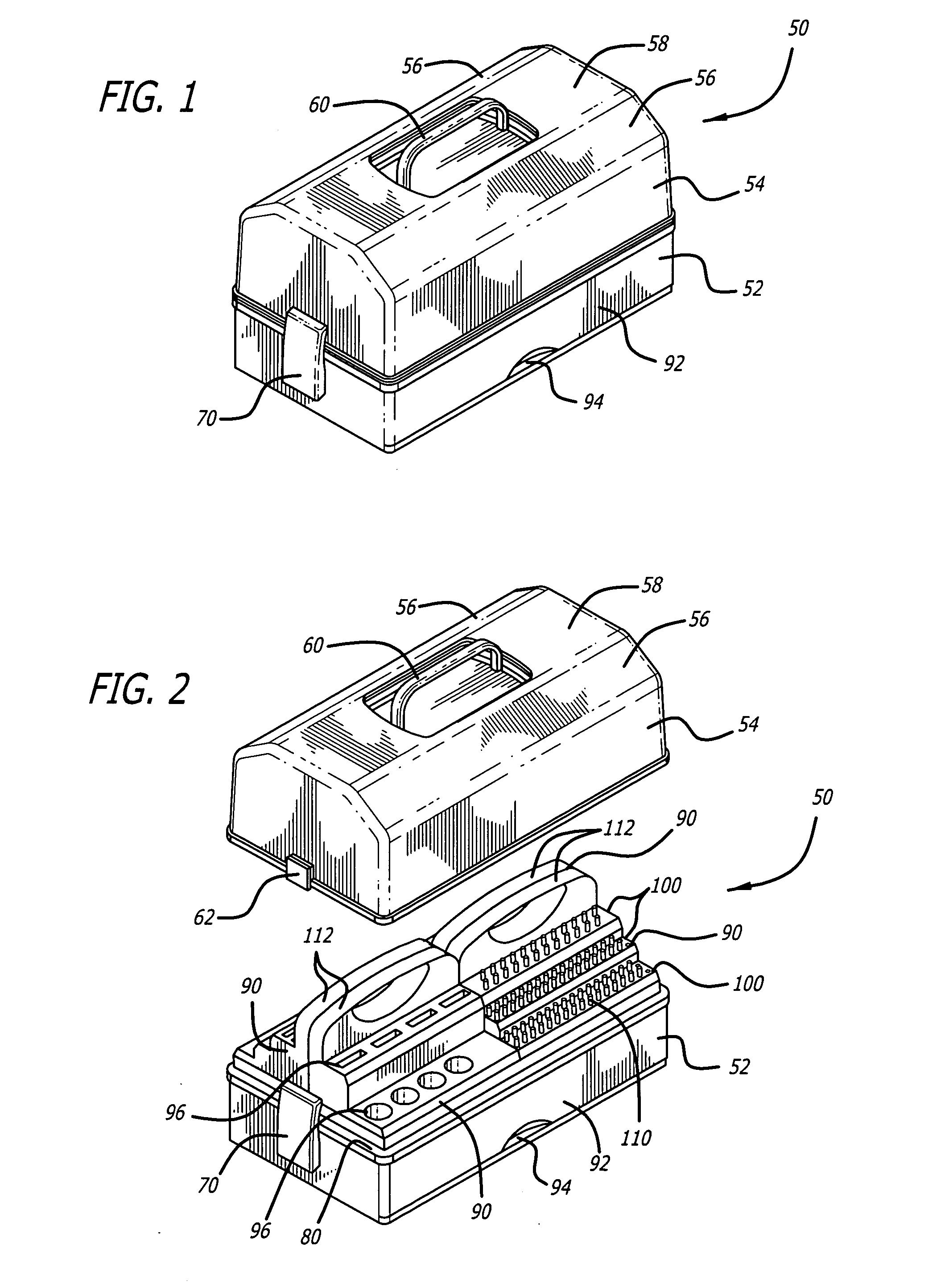

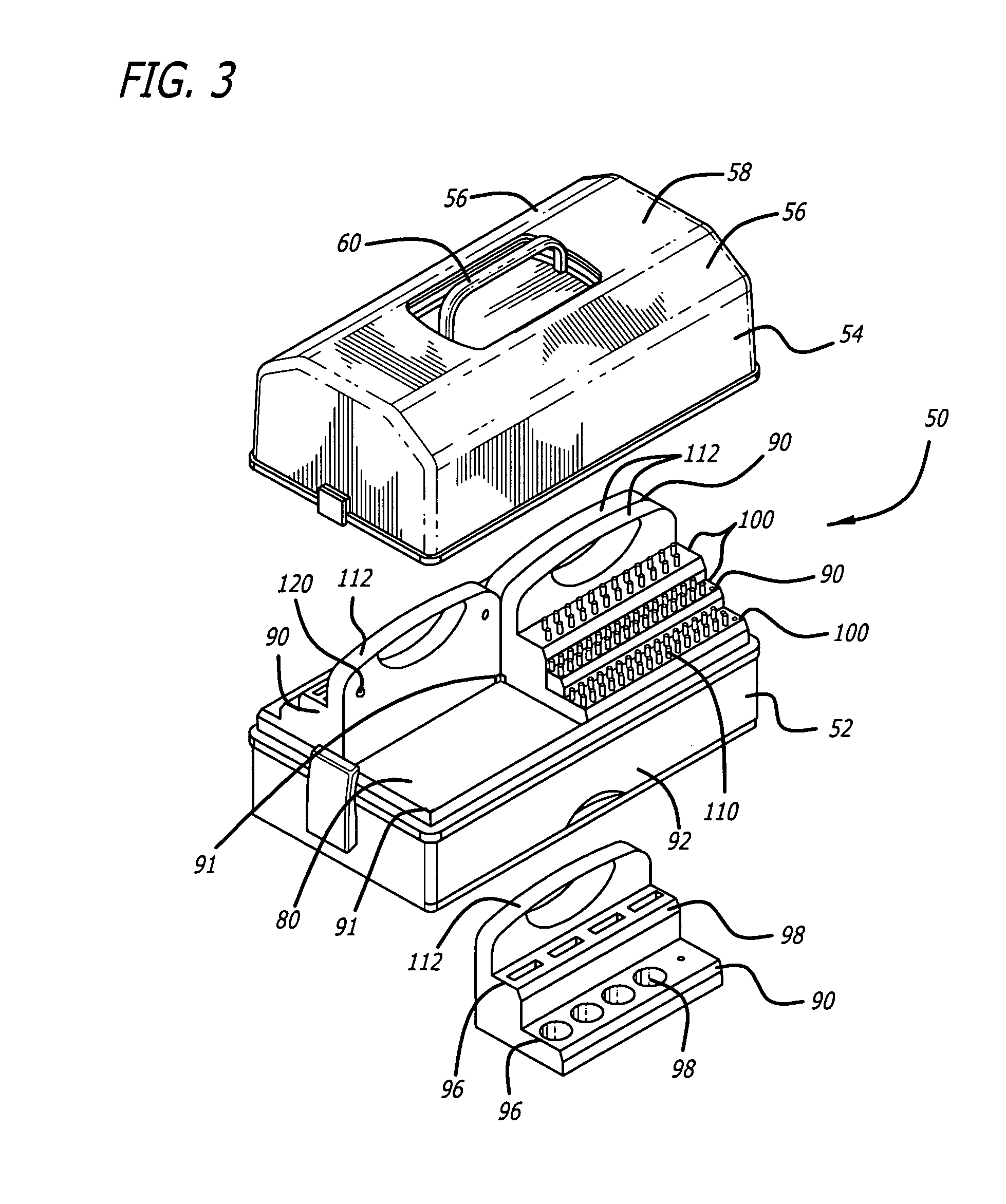

[0027]With reference to the drawings which are provided by way of example and not limitation, there is shown a tool case incorporating various features of the present invention. It is to be understood that a number of different embodiments are contemplated and that one particular embodiment may include all or fewer than all of the features of the present invention. The tool case includes modular components which can be displayed separate from a base and cover of the tool case. The tool case also embodies structure lending itself to conducting a quick inventory of its contents. An additional structural configuration is disclosed which facilitates the use of light weight translucent materials to enable inspection of the interior of the case.

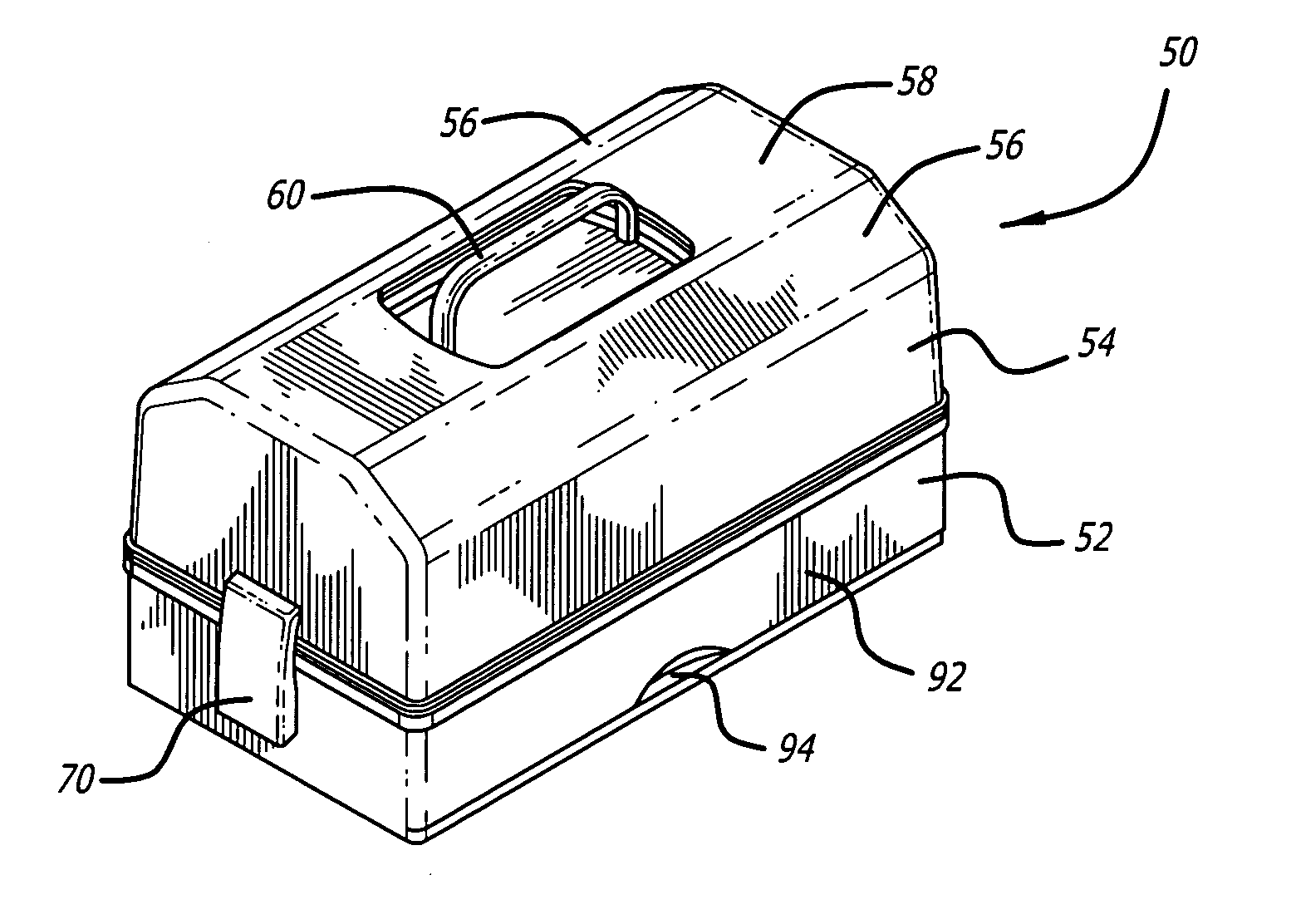

[0028]As shown in FIGS. 1 and 2, in one embodiments the present invention is embodied in a tool case 50 including a base 52 and a cover 54. Although various configurations are contemplated, the tool case 50 is generally rectangular in shape with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com