Severable film package for stacked product pieces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example

DETAILED DESCRIPTION OF THE DRAWINGS

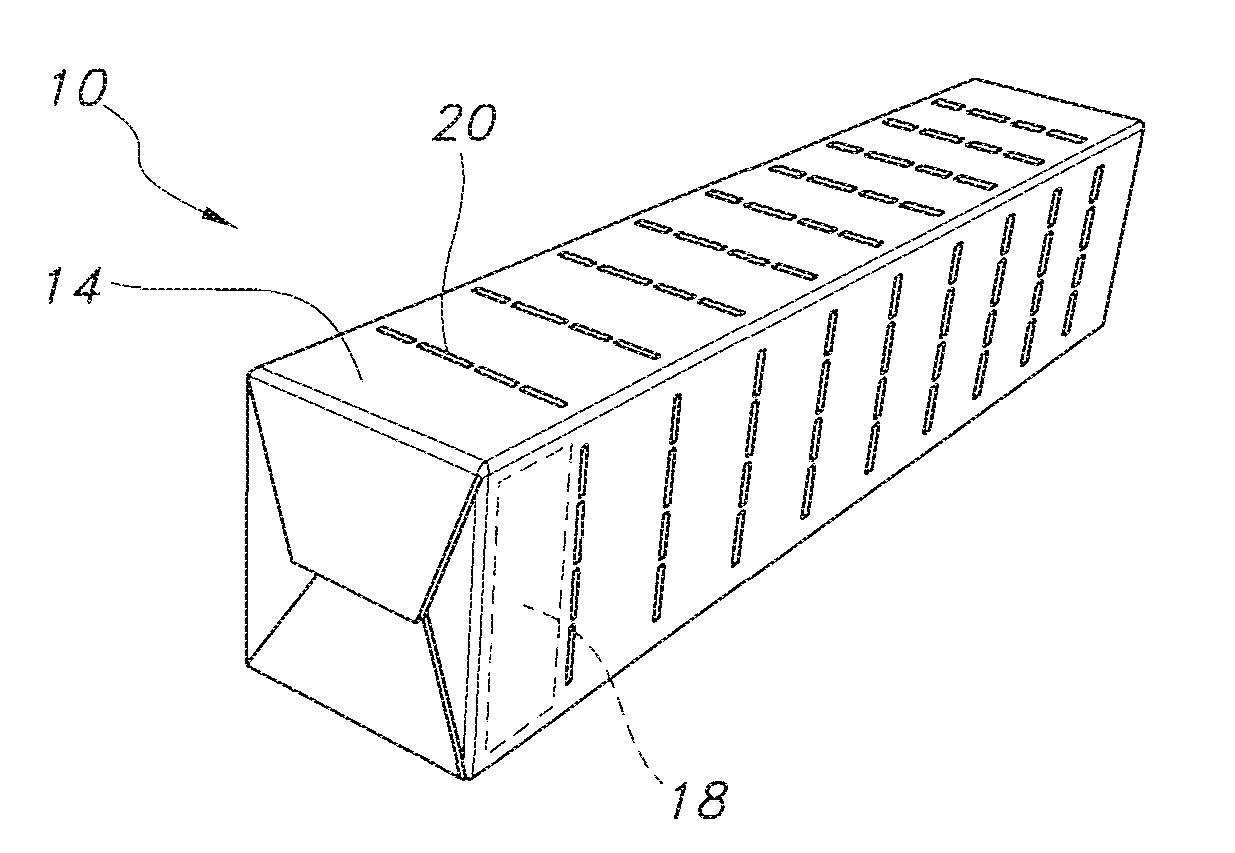

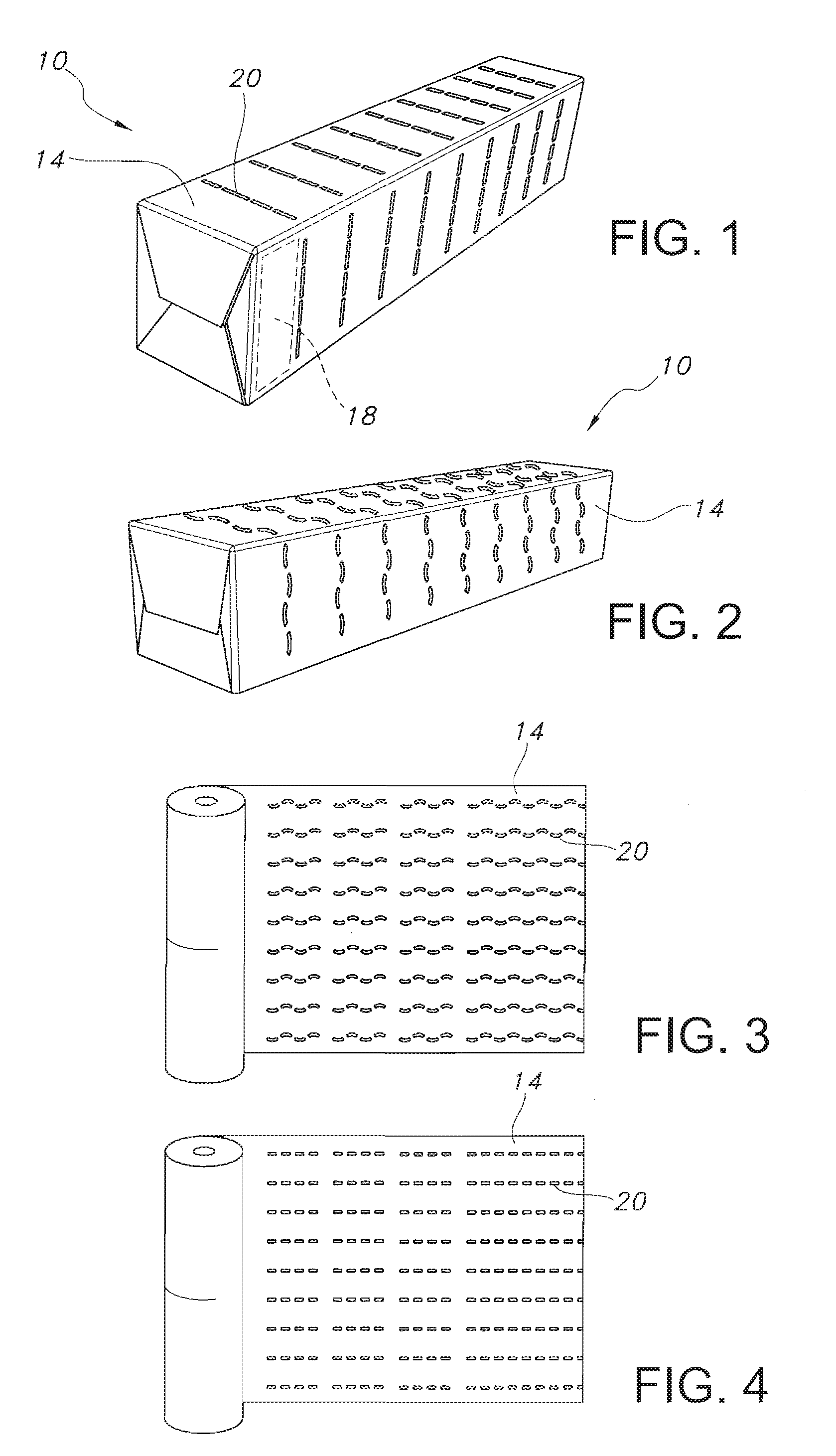

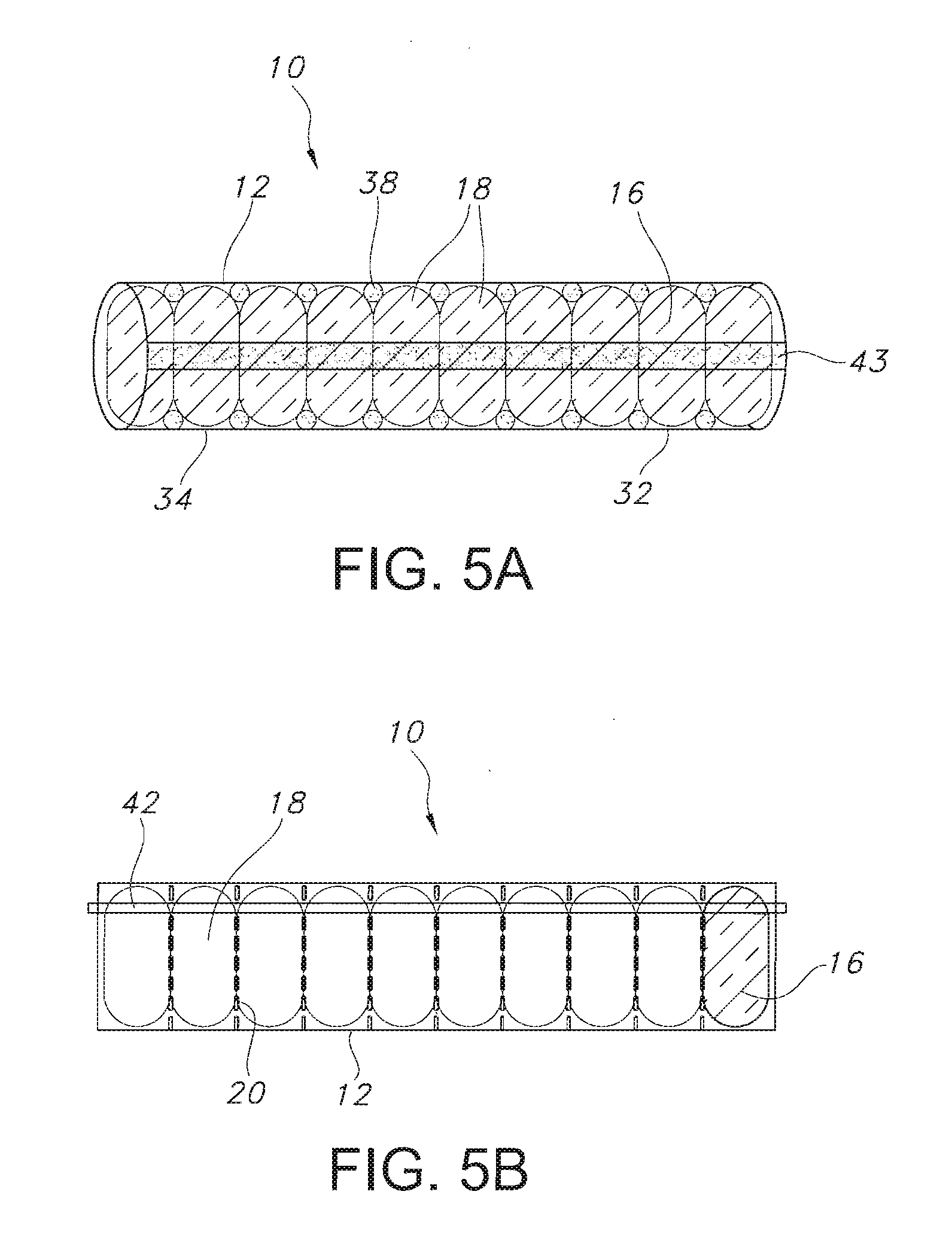

[0022]The present invention provides various embodiments directed to a packaging device for supporting a plurality of consumable product pieces in longitudinal or stacked array, in sealed accommodation. The packaging device provides retaining support for the plurality of consumable product pieces as well as ease in dispensing one or more of the consumable product pieces from the packaging 10. Consumable products or product pieces, as used herein, may include but not be limited to confectionery products, such as gum and candy, lozenges, stacked product pieces, and the like.

[0023]The embodiments of the present invention relate generally to a packaging device for a plurality of consumable product pieces that are arranged and packed in a longitudinally adjacent direction to one another. The packaging device of the present invention allows for the consumable product pieces to be stored and dispensed from their longitudinally adjacent configuration, The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Shape | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com