Container closure sterilising unit

a sterilising unit and container technology, applied in the field of container processing, can solve the problems of not being able to guarantee complete, reliable sterilisation, and ionising radiations failing to fully perform their functions, and positively affecting the environmental effect of sterilising agents using sources of ionising radiation as sterilising agents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

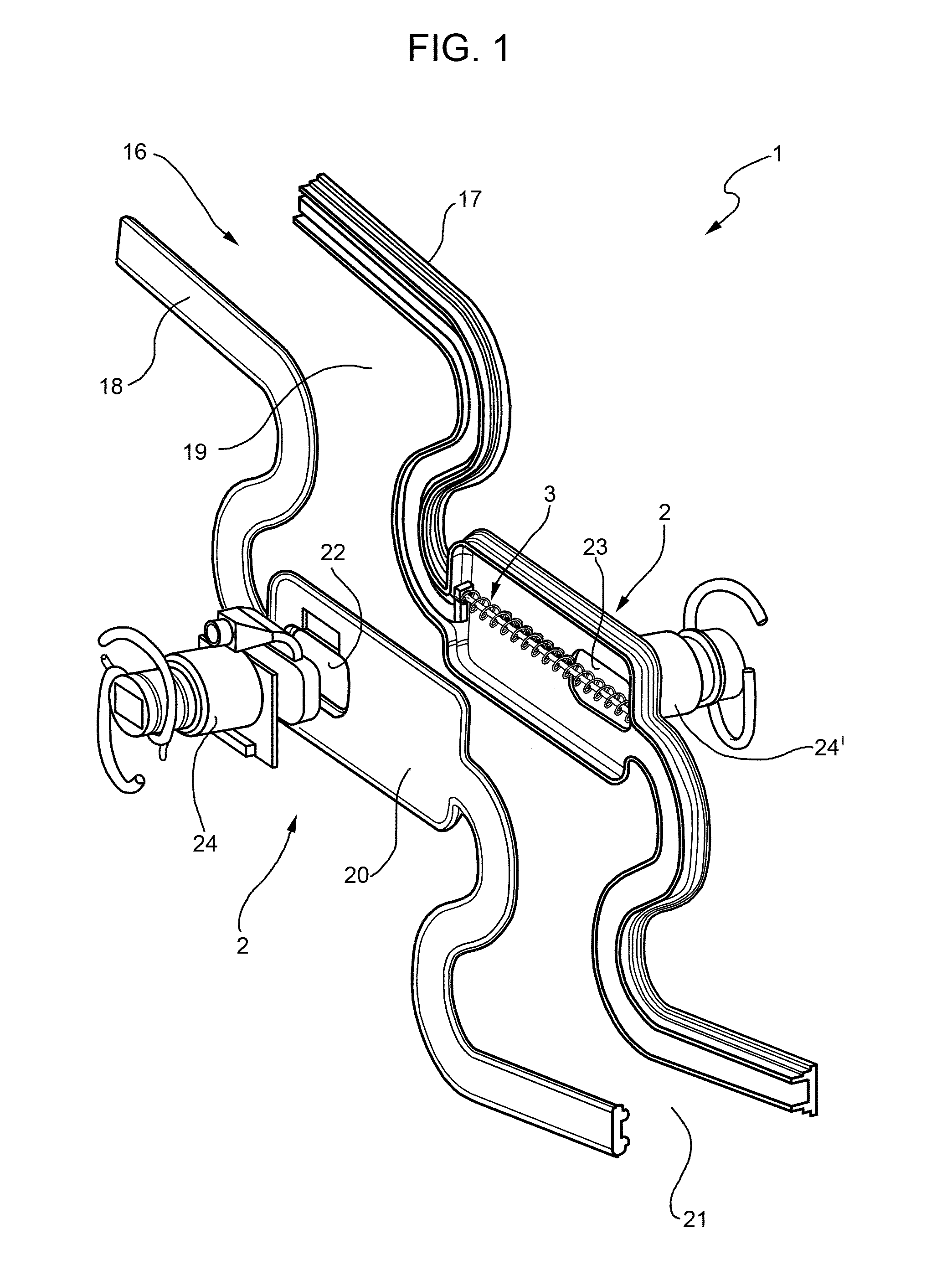

[0027]Number 1 in FIG. 1 indicates as a whole a container closure sterilising unit, in particular for caps and stoppers to be applied to relative containers, such as bottles.

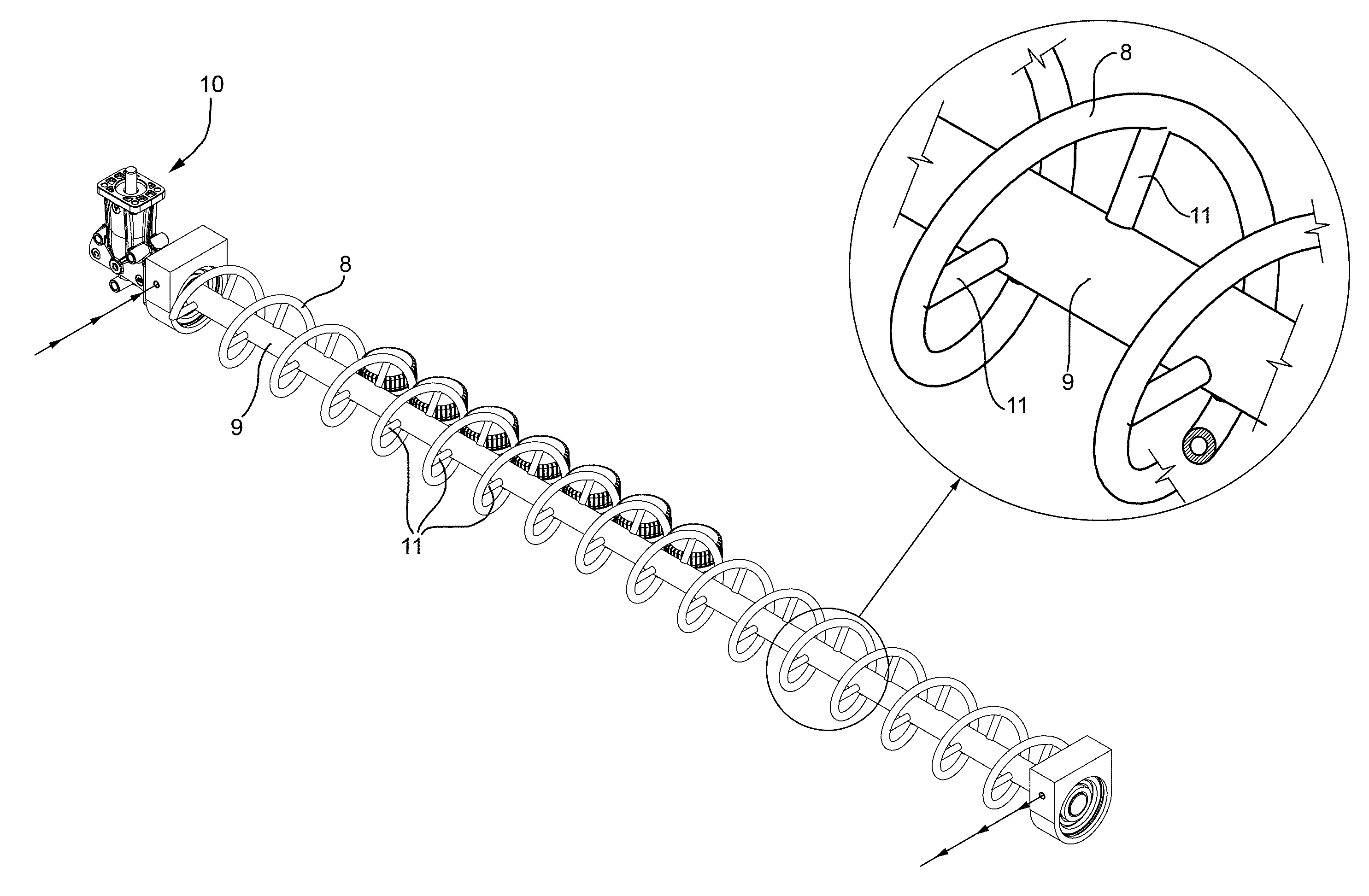

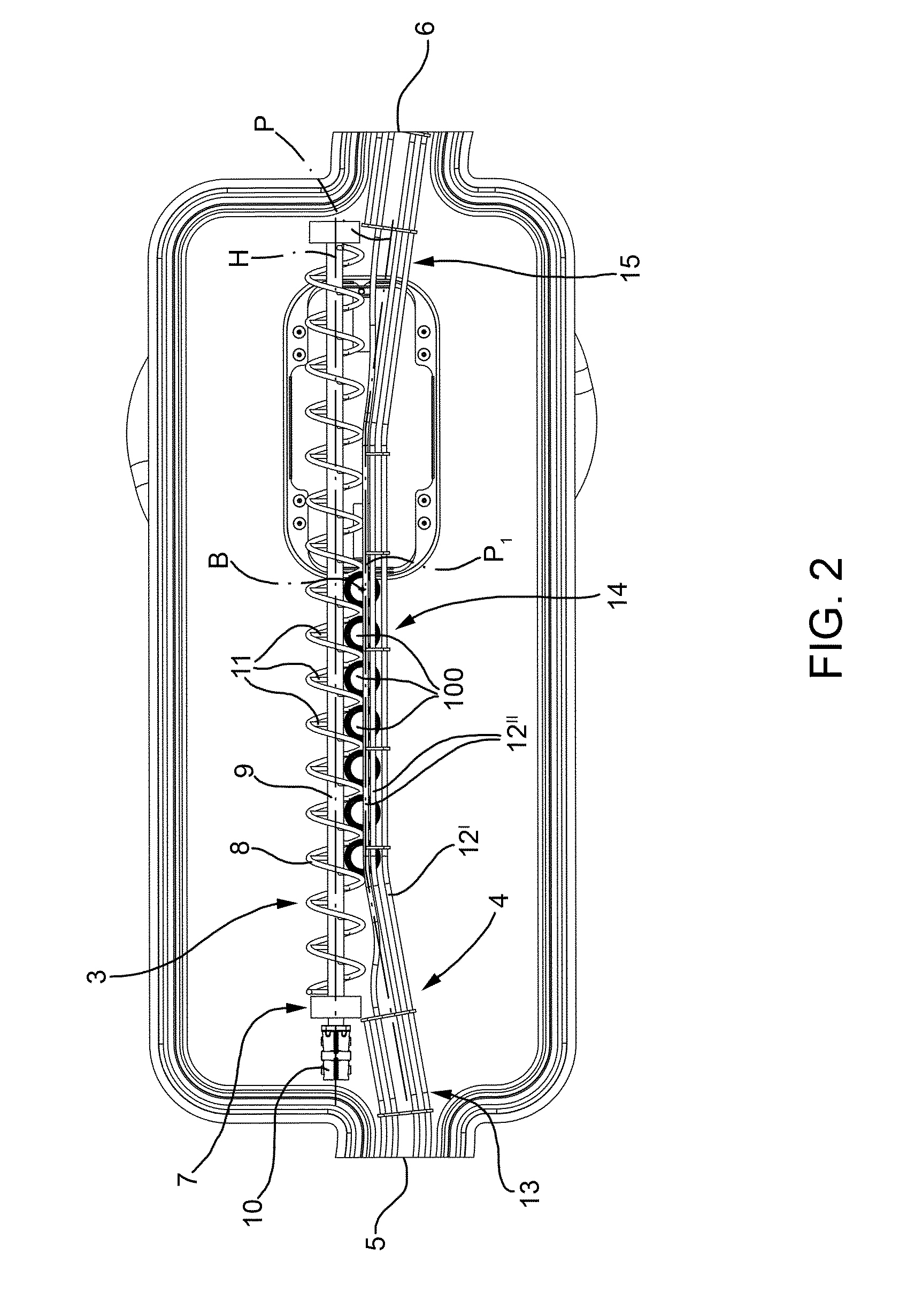

[0028]Sterilising unit 1 comprises at least one closure treatment station 2 and a device 3 for feeding a plurality of container closures 100 (see FIGS. 2 and 3) to closure treatment station 2.

[0029]As illustrated in greater detail in FIG. 2, feeding device 3 comprises guiding means 4 defining: an entrance 5 for closures 100, which entrance 5 communicates with loading means or a closure storage unit (not shown) from which closures 100 to be sterilised are supplied; a conveying path P comprising at least one linear tract P1 (i.e. one tract having constant inclination relative to the vertical direction) and along which the at least one treatment station 2 is arranged; and an exit 6 for closures, which exit 6 communicates with a further unit (not shown) arranged downstream from sterilising unit 1.

[0030]Advantageousl...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap