Modular system

a module system and modular technology, applied in the field of modules, can solve the problems of affecting the use of modules, not providing specifics, and the assembly method of the system is rather complicated, and achieve the effect of simple and secure way

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

second embodiment

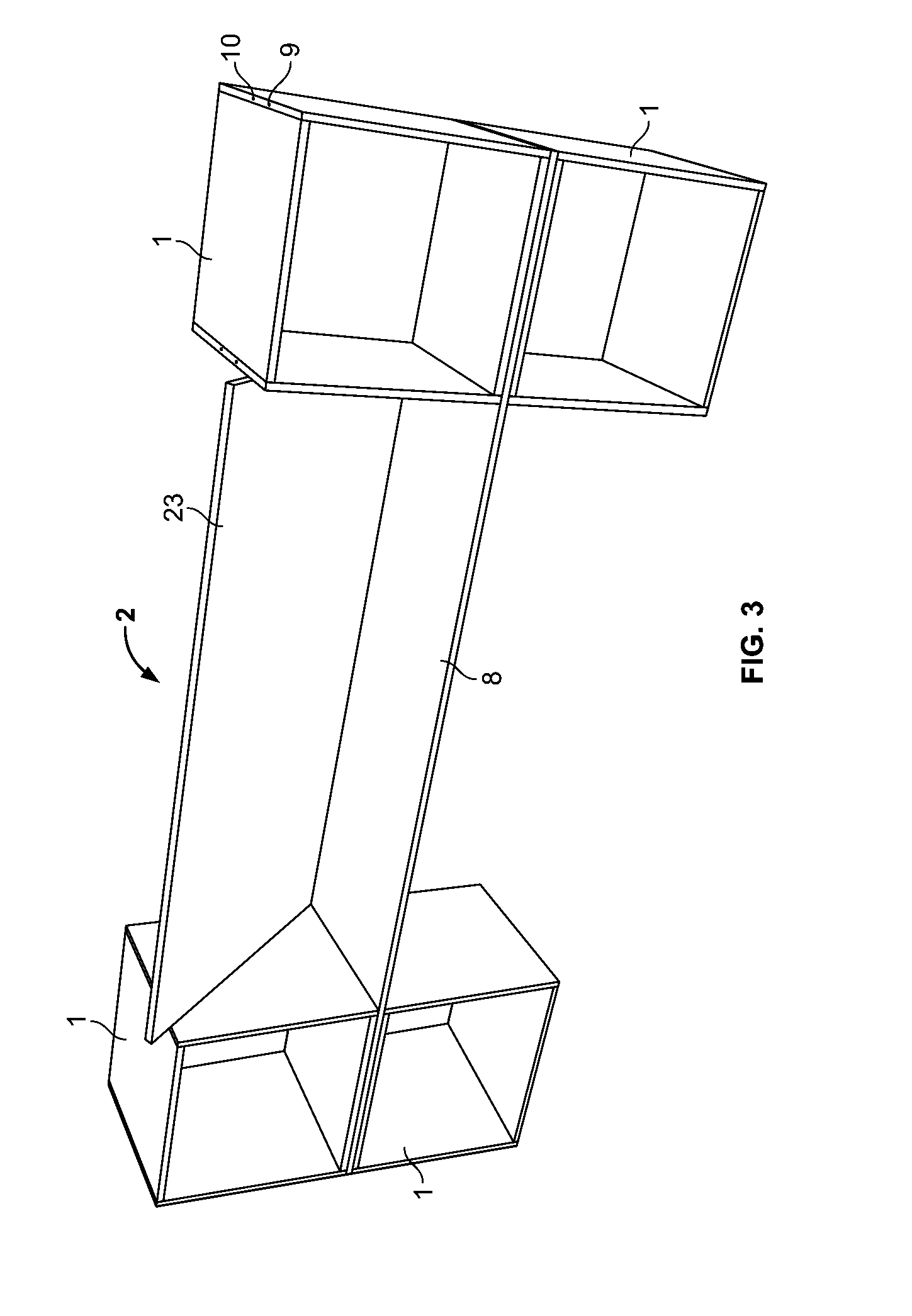

[0038]FIG. 3 shows a modular system (2) according to the invention as this comprises a very long extension panel (8), said extension panel being rectangular and extending from the placement between a left module rack consisting of an upper module (1) and a lower module (1) wherebetween the extension panel (8) is arranged and secured with its fastening means as stated above with reference to FIG. 2. At the other end, the extension panel (8) is also placed between a module rack, i.e. the right side is placed in a corresponding way between upper and lower modules and likewise with its fastening means (12) fixed to their positioning means (9). This way a less compact shelf system is achieved and an additional shelf is provided without having to use several modules (1) which are the expensive part. Further, it is possible to place a loose board (23) on top of the long rectangular extension panel (8), said loose board thus being able to constitute a desk top with extra width. If after the...

third embodiment

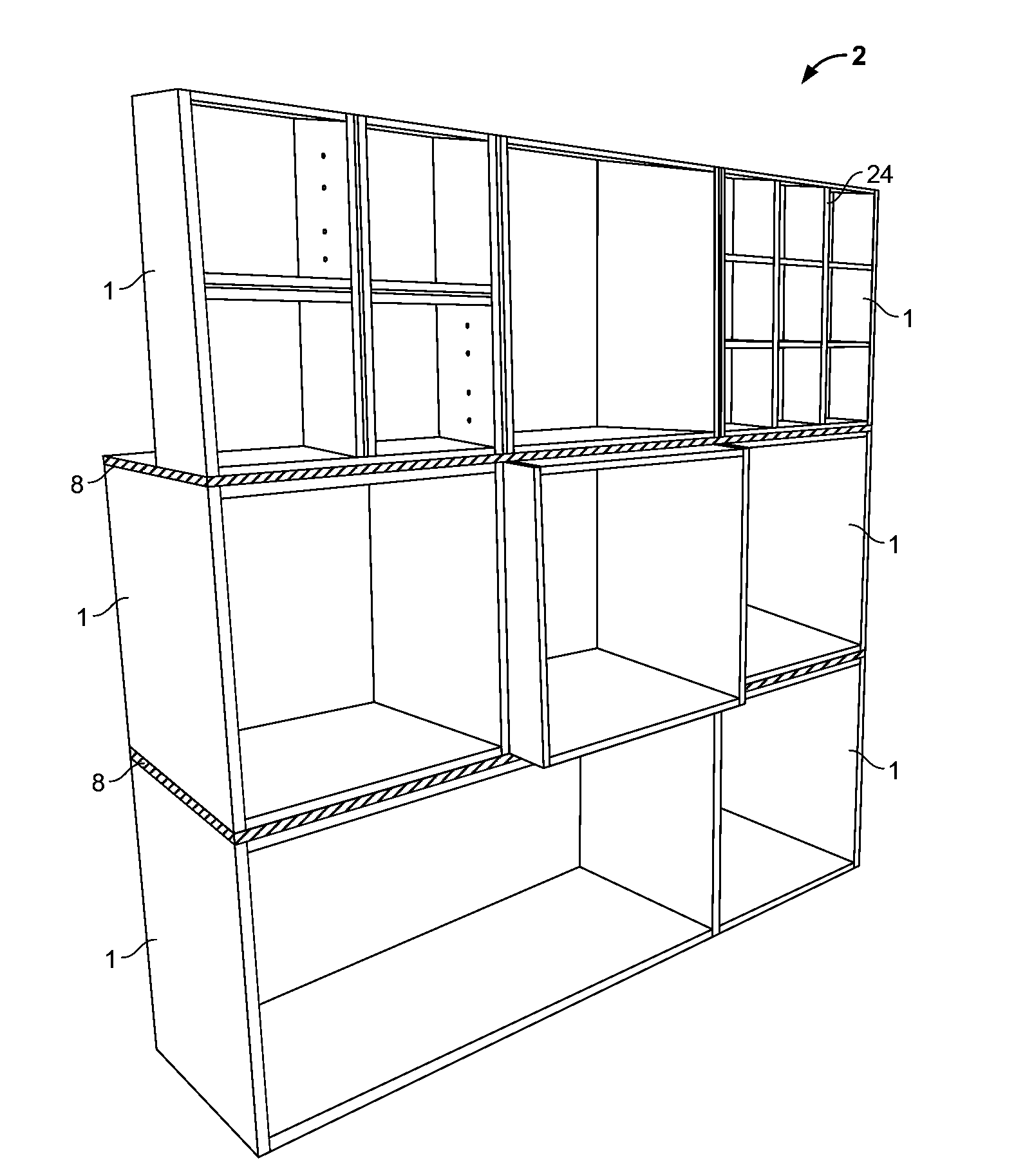

[0039]FIG. 4 shows a modular system (2) according to the invention which is also constructed by the previously described modules (1) and extension panels (8). In this case the modules (1) are shaped in rectangular and square units, but with very different sizes, and as is also evident, the actual modules may naturally also be offset in relation to each other so that a front surface of a module can be offset in relation to the front surface of the module below. Inside the individual modules it is also possible to insert a partition (24) for separating each individual module into even smaller compartments.

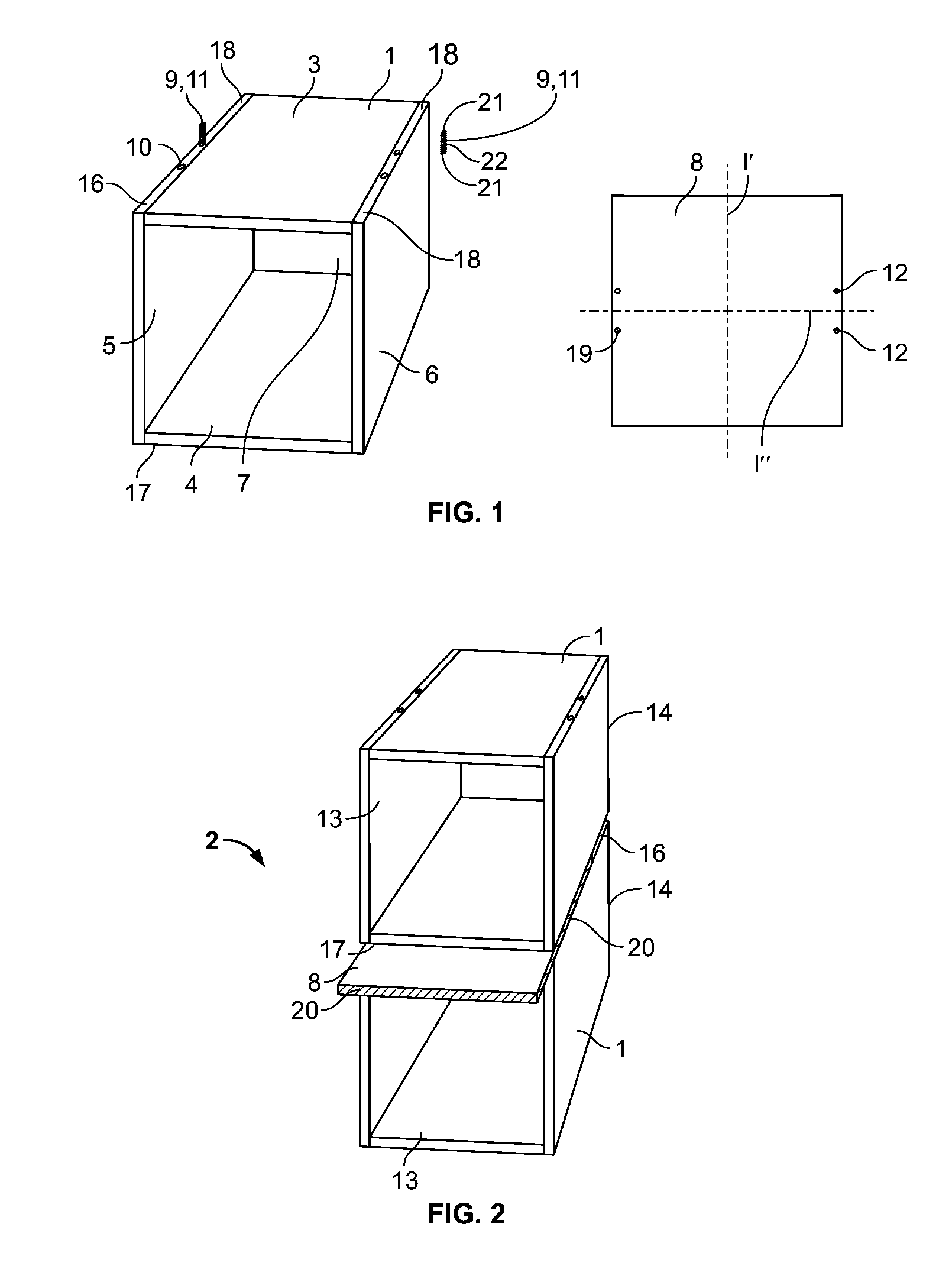

[0040]It is noted that the shelf top panel (3) and the shelf bottom panel (4) in each module (1) have the same geometry and dimension and are rectangular or square boards.

[0041]Each module (1) is comprised by boards being assembled with known joining elements as is known from other types of furniture which can be assembled at home. By assembly of the square or rectangular boards, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| distance | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com