Multifunction pulp stopping plug for anchor rod and its pulp filling adaptor

A technology of grouting joints and grouting stoppers, which is applied in construction, sheet pile walls, foundation structure engineering, etc., can solve problems such as grouting, and achieve the effect of simple grouting, simple structure, and full and uniform grouting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

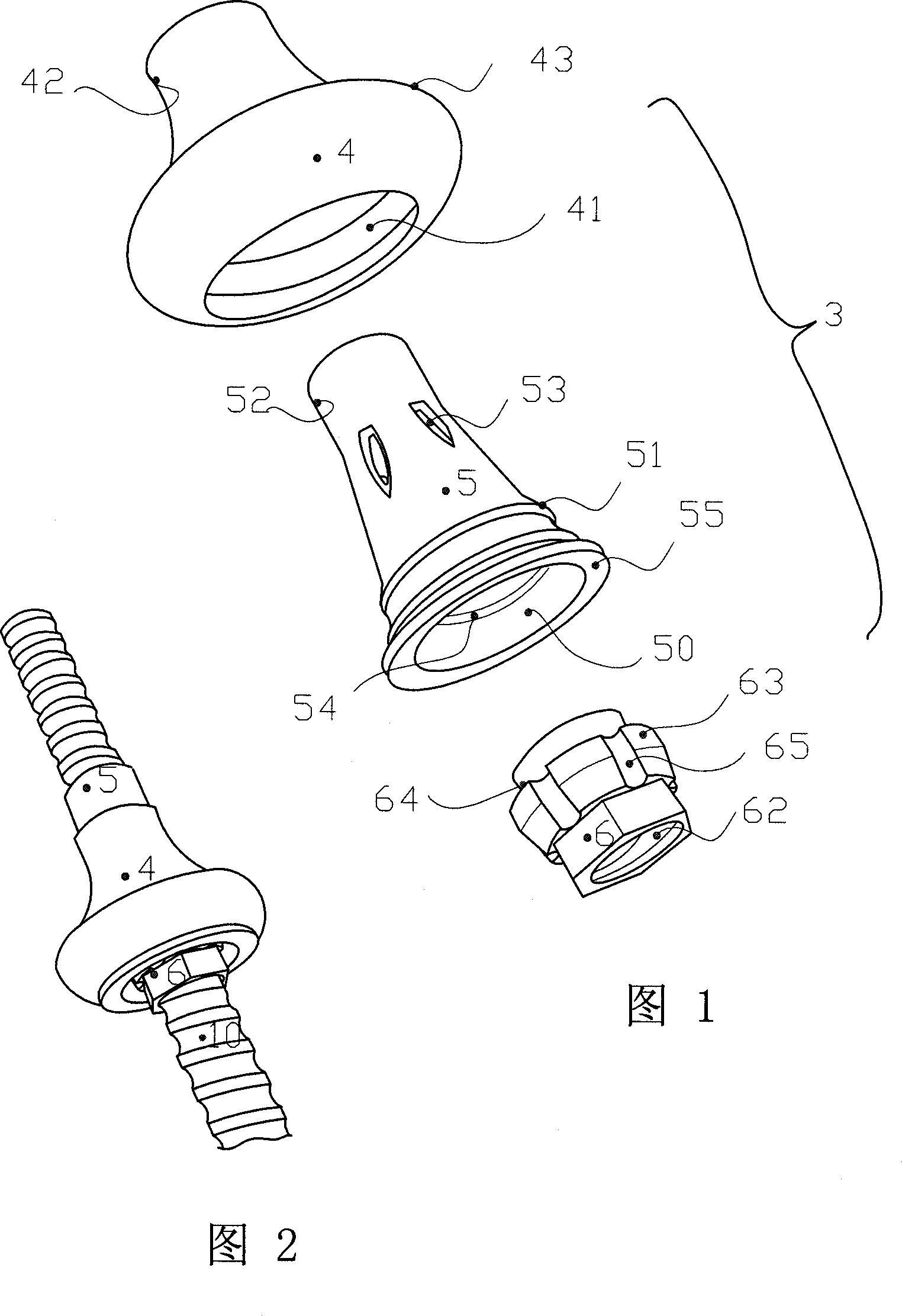

[0048] A grout stopper 3 as shown in FIG. 1 and FIG. 2 is composed of a flexible outer ring 4 , a hard inner ring 5 with a grouting hole 53 , and a locking member 6 with a longitudinal groove 63 . The flexible outer ring 4 is sleeved on the hard inner ring 5, and the locking part 6 is closely attached to the bell mouth of the hard inner ring 5, so that the grout stopper 3 formed in this way passes through the inner hole 62 of the locking part 6 It is threadedly connected with the surface of the anchor rod body 10 . The longitudinal groove 65 of the locking member 6 communicates with the inner cavity 50 of the hard inner ring 5 and the grouting hole 53 to form a grouting channel.

[0049] The flexible outer ring 4 is an inverted trumpet body with a cavity and the front and rear ends are connected. The front end 42 is small and thin, and the rear end 43 is large and thick. Its front end 42 is a high-elastic thin-layer ring, and the inner surface of the cavity is smooth, and can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com