Vane pump

A vane pump and vane technology, used in pumps, pump components, rotary piston pumps, etc., can solve problems such as pump efficiency drop, and achieve the effect of reducing load and oil pressure pulsation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

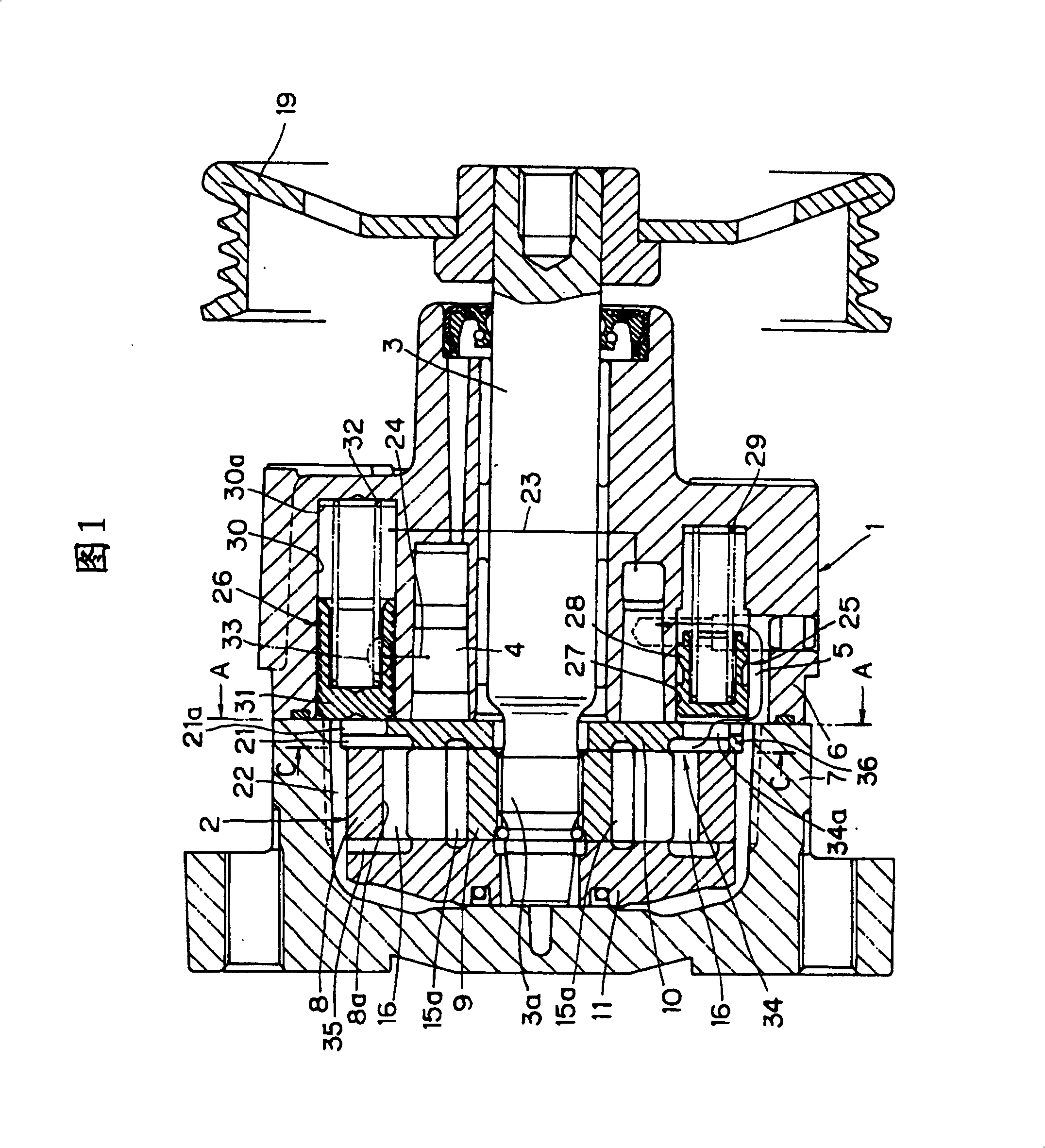

[0033] Next, embodiments of the vane pump of the present invention will be described in detail with reference to the drawings.

[0034] This vane pump is a pump suitable as a supply source of oil pressure for a hydraulic machine such as a power steering device of a vehicle, like a conventional pump. As shown in Fig. 1, it is mainly driven by a pump casing 1 fixed to a cylinder block of an internal combustion engine with screws, a pump main body 2 arranged in the pump casing 1, and a drive unit with one end side inserted inside the pump casing 1. Axis 3 constitutes.

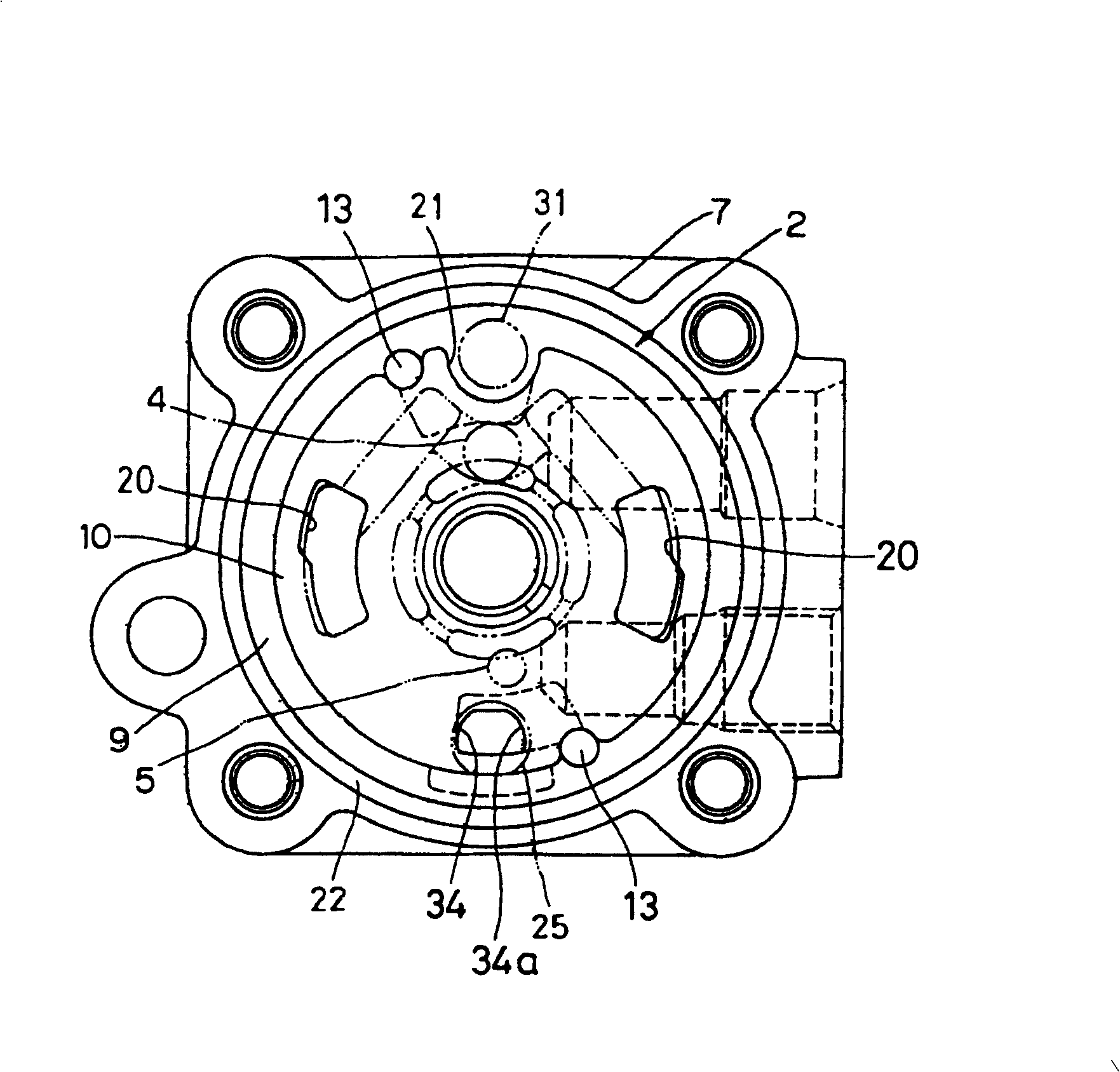

[0035] Described pump housing 1 is as shown in Figure 1 and figure 2 As shown, it consists of a block-shaped pump body 6 with a suction passage 4 and a discharge passage 5 and a pump cover 7 combined with the pump body 6, and a space for placing the pump body 2 is provided between the pump body 6 and the pump cover 7. department.

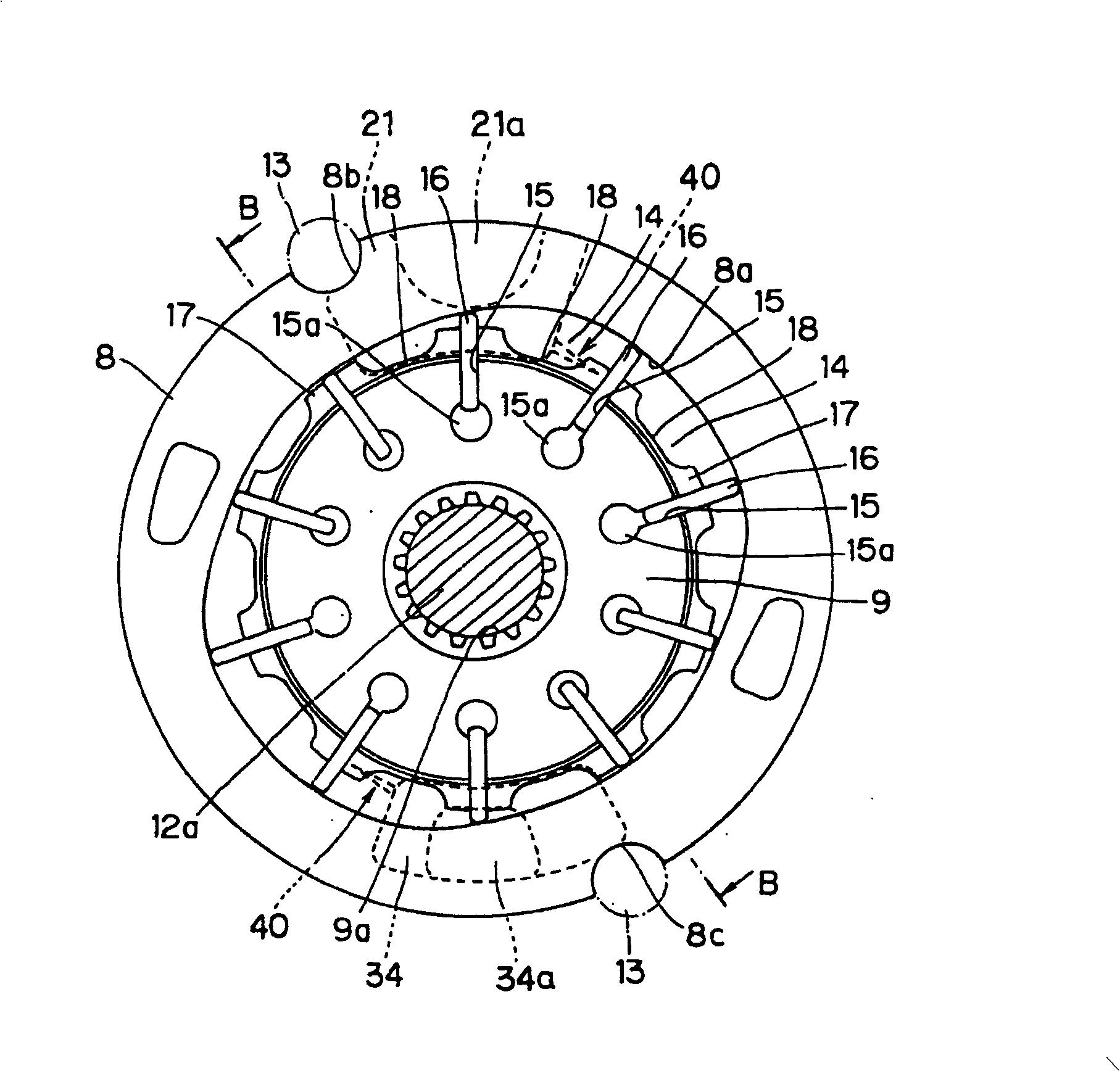

[0036] Described pump main body 2 is as shown in Figure 1~ Figure 4 As shown, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com