Disk clamping device

A technology of clamping device and clamping rod, which is applied in the field of disk clamping device, can solve the problems of insufficient reliability of loading device and low performance of disk clamping device, and achieve the effect of stable pressing force and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment

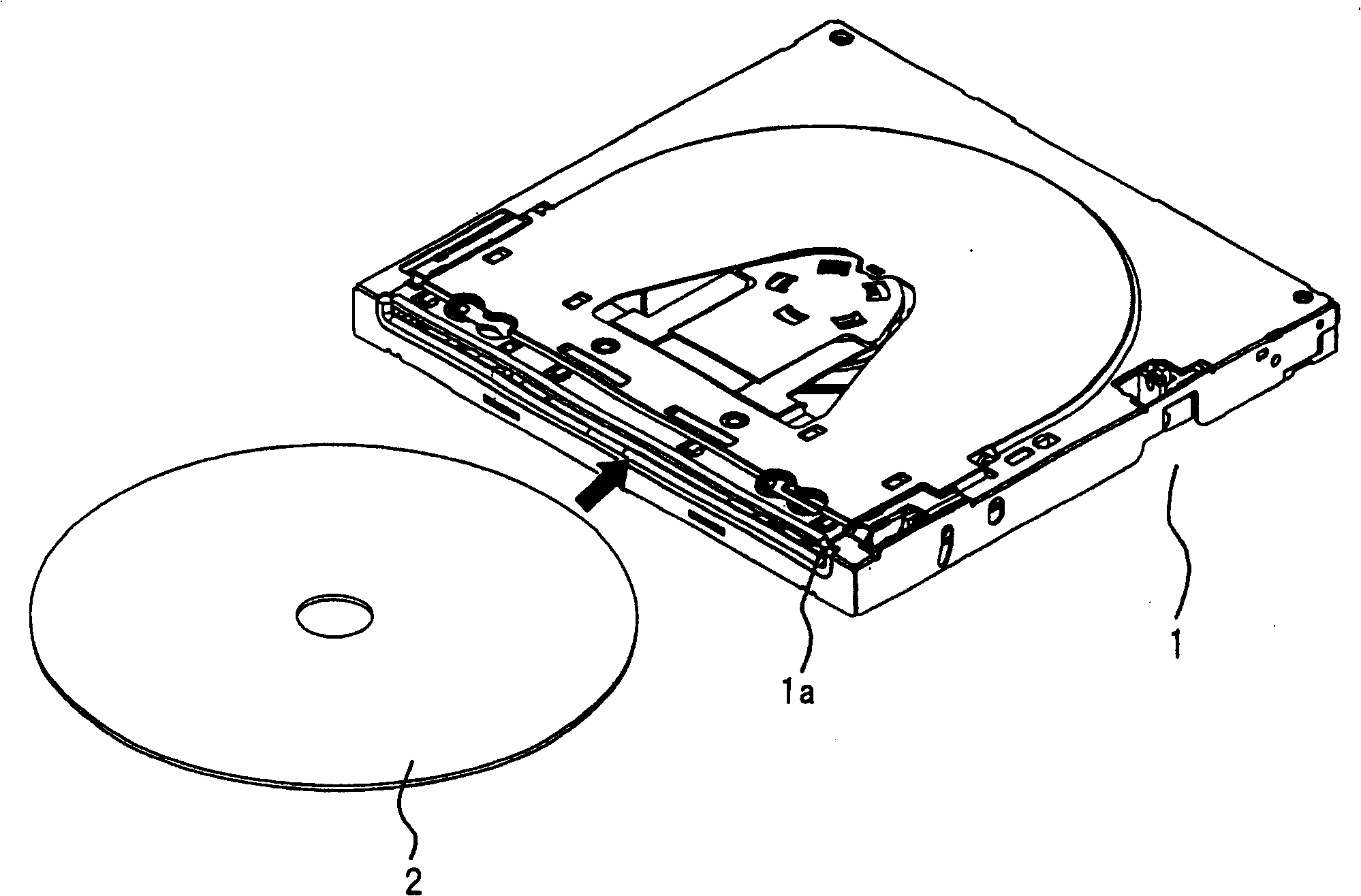

[0041] refer to Figure 1 to Figure 8 , the loading device provided with the disc clamping device according to the first embodiment of the present invention will be described. figure 1 It is a diagram showing a schematic configuration of a slotting system loading device in this embodiment. figure 1 In the loading device 1, when a disk 2 is inserted from the disk insertion port 1a, a part of the inserted disk 2 is clamped and loaded into the device, and the disk 2 is seated on the turntable (turntab1e) inside the loading device 1. given location.

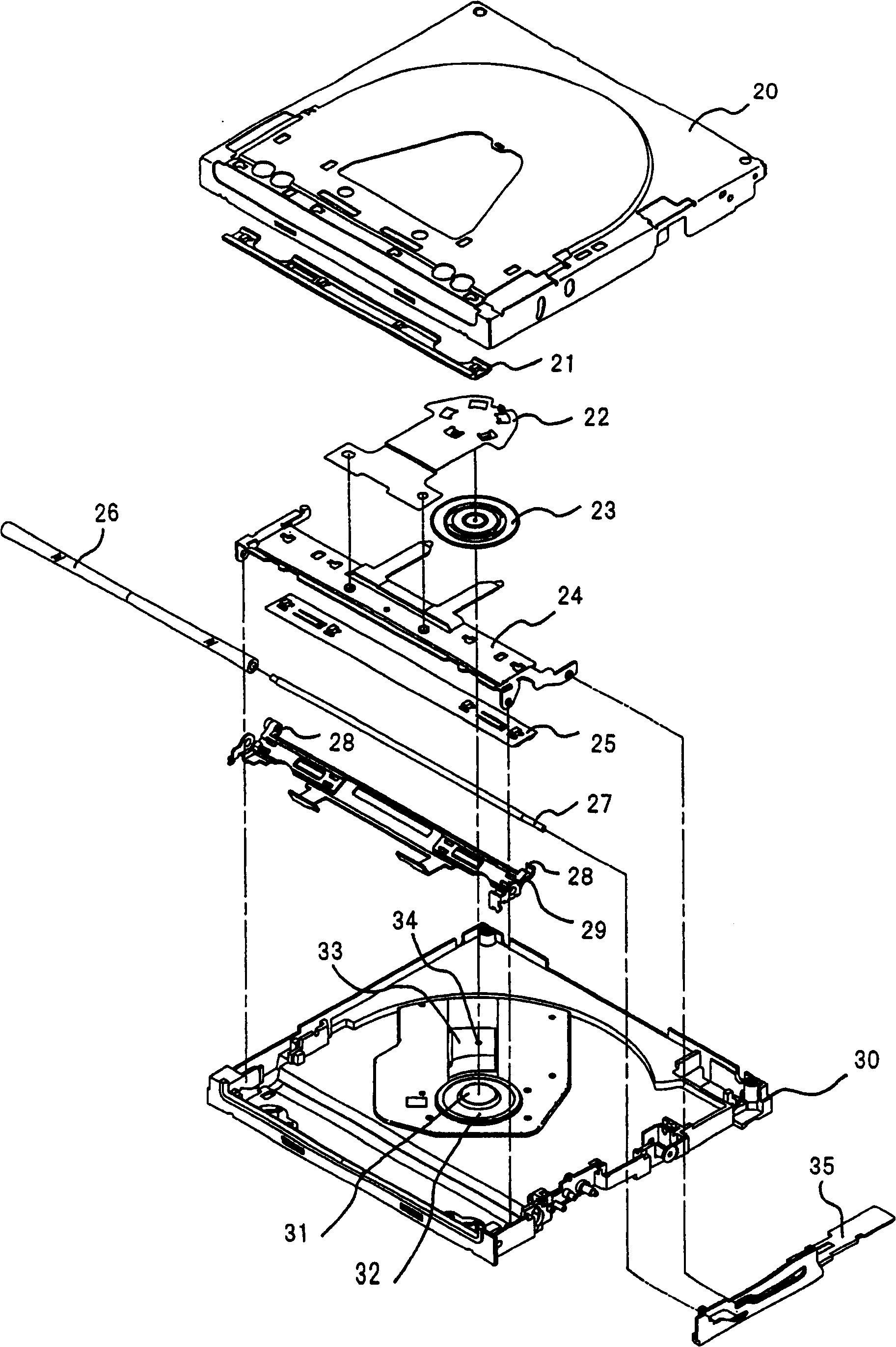

[0042] figure 2 express figure 1 An exploded perspective view of the loading device 1 in .

[0043] Disk insertion port 1a ( figure 1 ), formed by the base plate 20 and the mechanical base plate 30. The disc guide 21 is fixed near the disc insertion opening 1 a of the base pan 20 .

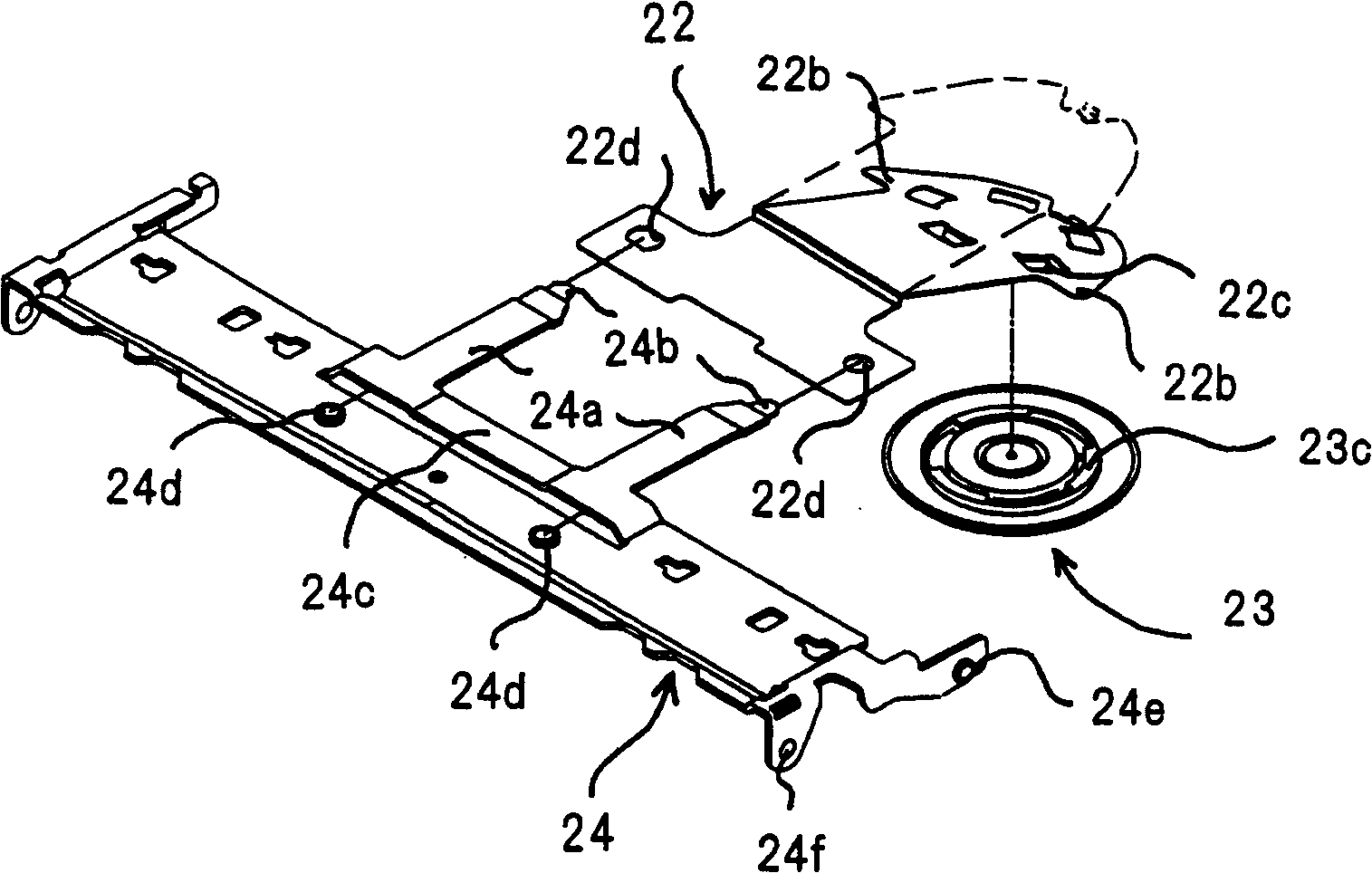

[0044] A leaf spring 22 is fixed on one side in a clamping lever 24 . The jig 23 is freely rotatably supported by the back of the leaf spring 2...

no. 2 Embodiment

[0073] Referring to Figs. 9 to 11, a description will be given of a loading device including a disc clamping device according to a second embodiment of the present invention. FIG. 9 is a schematic view showing the outline of the configuration of the slotting system loading device of the present embodiment. In FIG. 9, the loading device 100 of this embodiment, when inserting the disk 2 from the disk insertion port 100a, clamps a part of the inserted disk and carries it into the device, so that the disk 2 is seated on the inside of the loading device 100. The given position of the turntable.

[0074] FIG. 10 shows an exploded perspective view of the loading device 100 shown in FIG. 9 . In Fig. 10 , the point of having a leaf spring 22' instead of the leaf spring 22, the point of having a magnet 101 below the jig 23, and the point of having an adsorption plate 102 above the centering member 31, and figure 2 The loading device 1 of the first embodiment shown is different. In o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com