Waterproof armoured optical fiber and grease injection coating machine in protecting-layer apparatus

A technology of armored optical cable and armor layer, which is applied in the field of ointment injection device, can solve the problems of large wear of pneumatic pressure filling pump, easy carbonization of colloid, high price, etc., to reduce material and production costs, strong wear resistance and Corrosion resistance, the effect of precise control of the amount of paste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

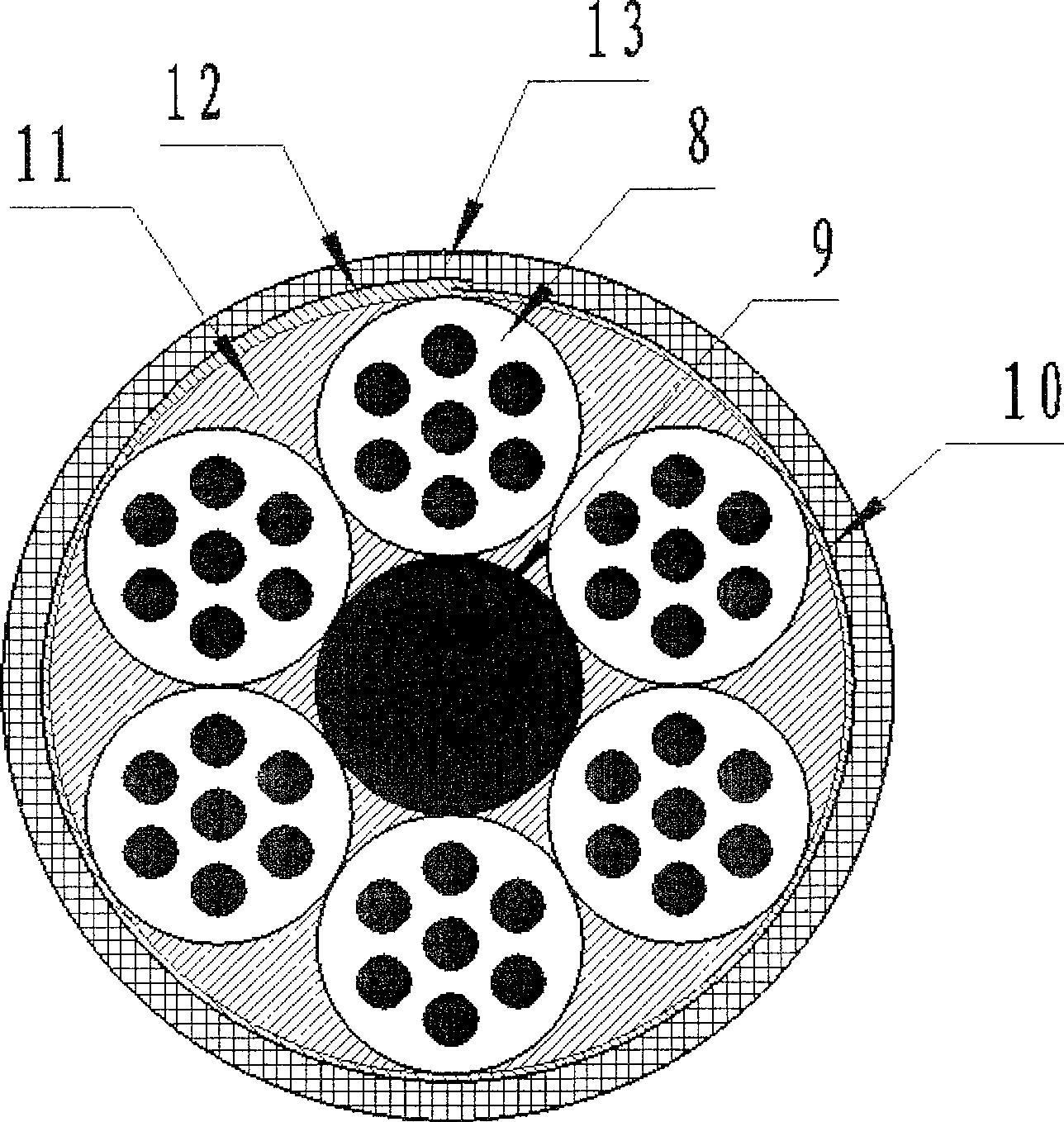

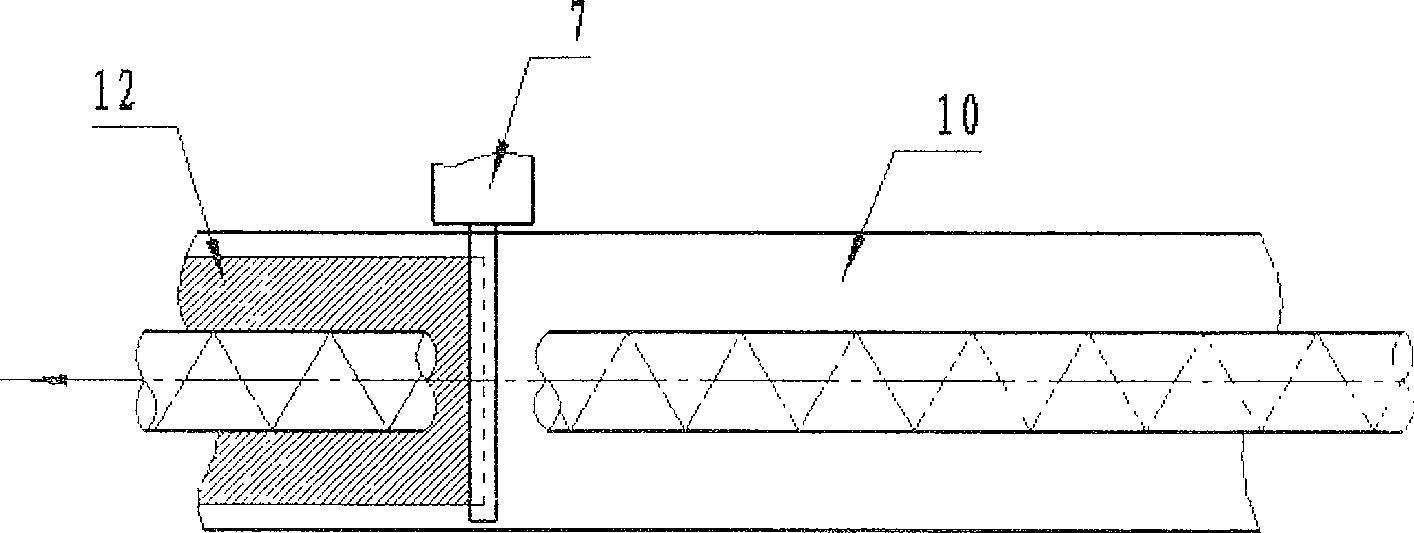

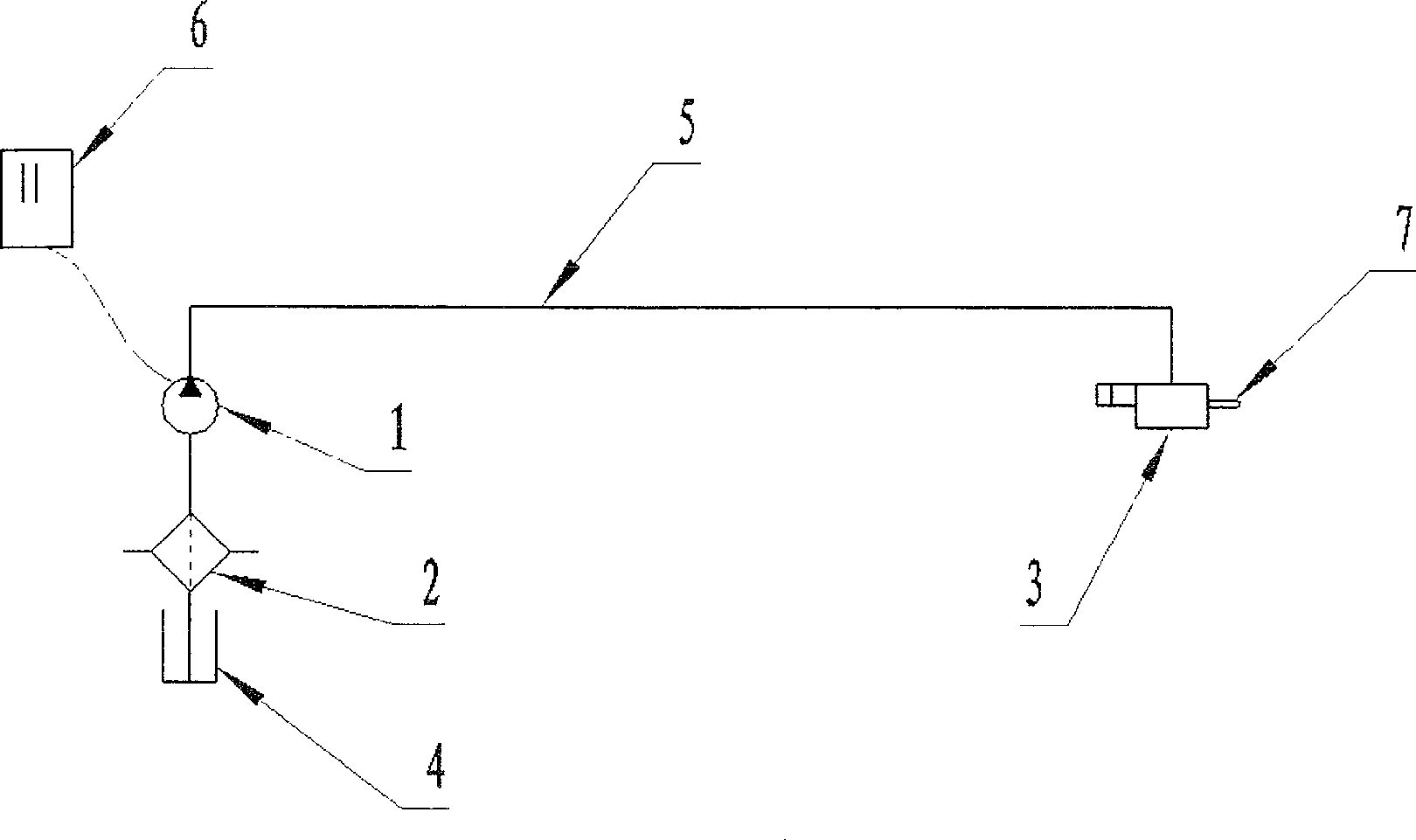

[0014] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings. Examples of layer-stranded waterproof armored optical cables figure 1 , 2 As shown, it includes a layer-stranded cable core, an armor layer 10 and an outer sheath 13. The layer-stranded cable core is formed by twisting a plurality of sleeves 8 with optical fibers and an intermediate reinforcing core 9. There are usually 5 to 12 casing tubes for the optical fiber, and the space between the tubes in the layer-stranded cable core is filled with waterproof ointment 11, and the layer-stranded cable core is covered with an armor layer 10, and the armor layer consists of The cable core is composed of steel strip or aluminum strip, and the inner surface of the armor layer is coated with a water-swellable ointment layer 12, which is to inject a layer of 1.5-2mm thick water-swellable ointment layer on the inner surface of the metal strip and then It is made of met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com