Full-automatic jacquard towel sample knitting machine

A prototype loom, fully automatic technology, applied in jacquard looms, looms, flannel looms, etc., can solve the problems of long trial production cycle, large loom vibration, and long consumption of labor hours.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

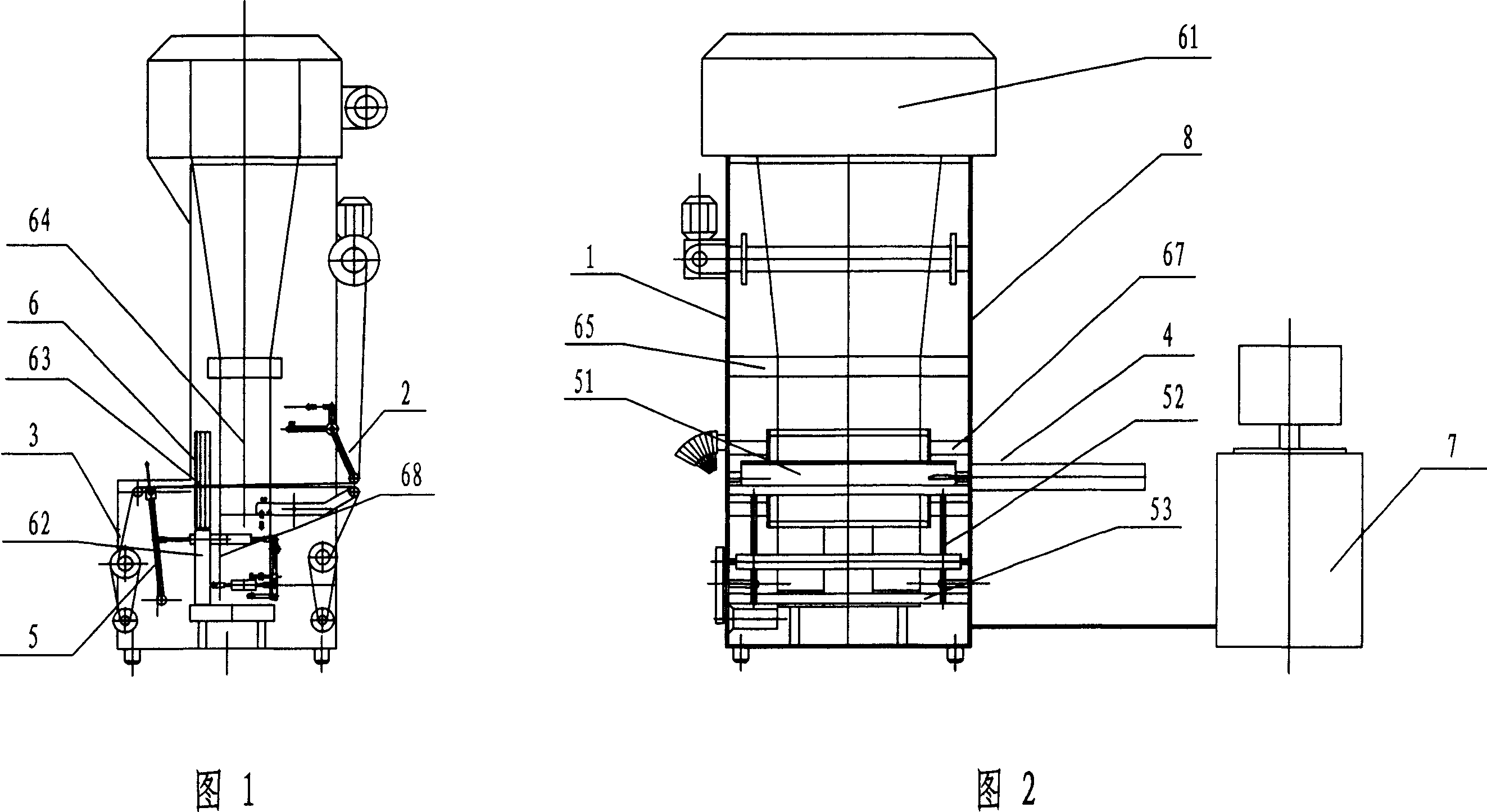

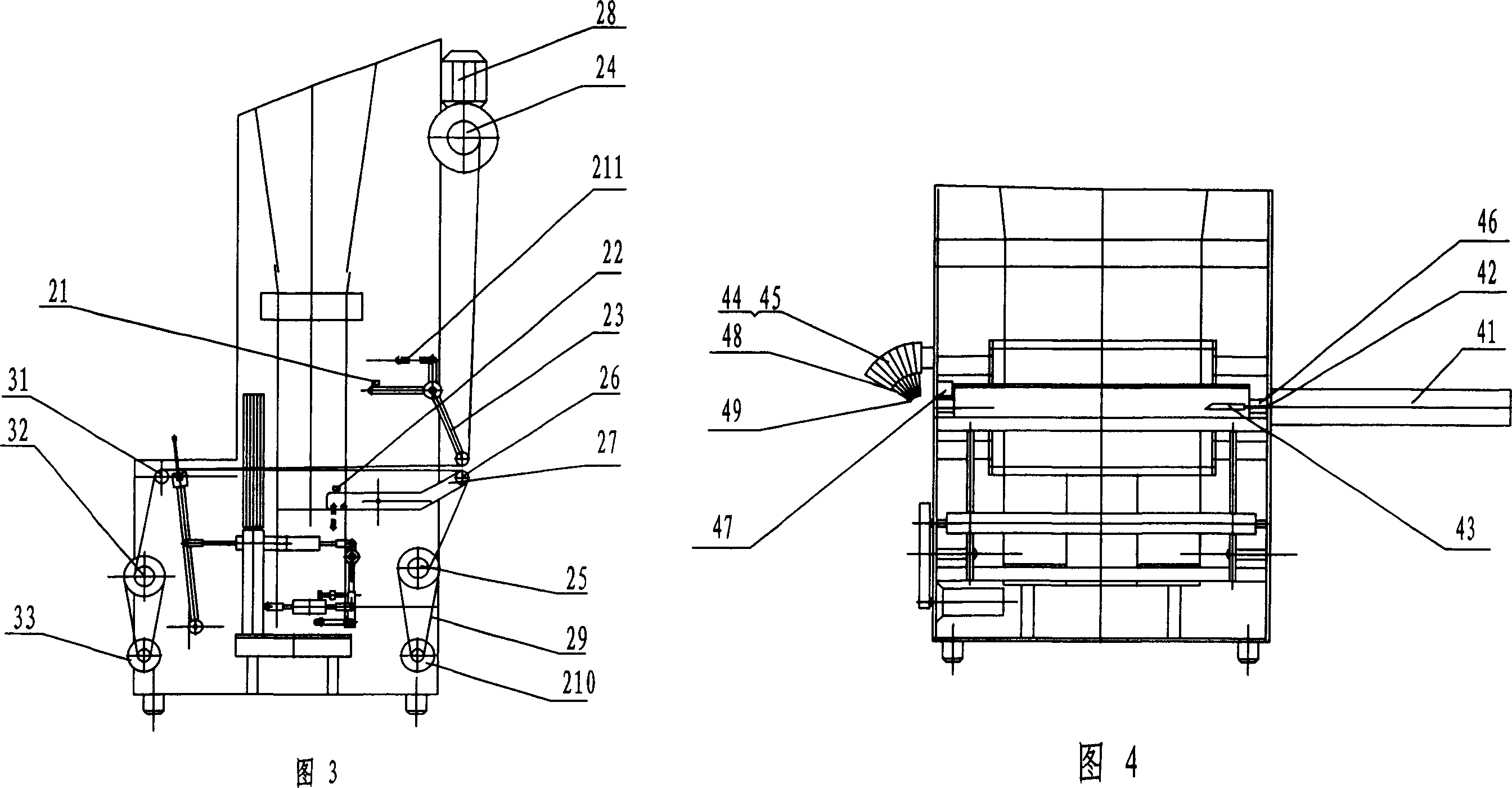

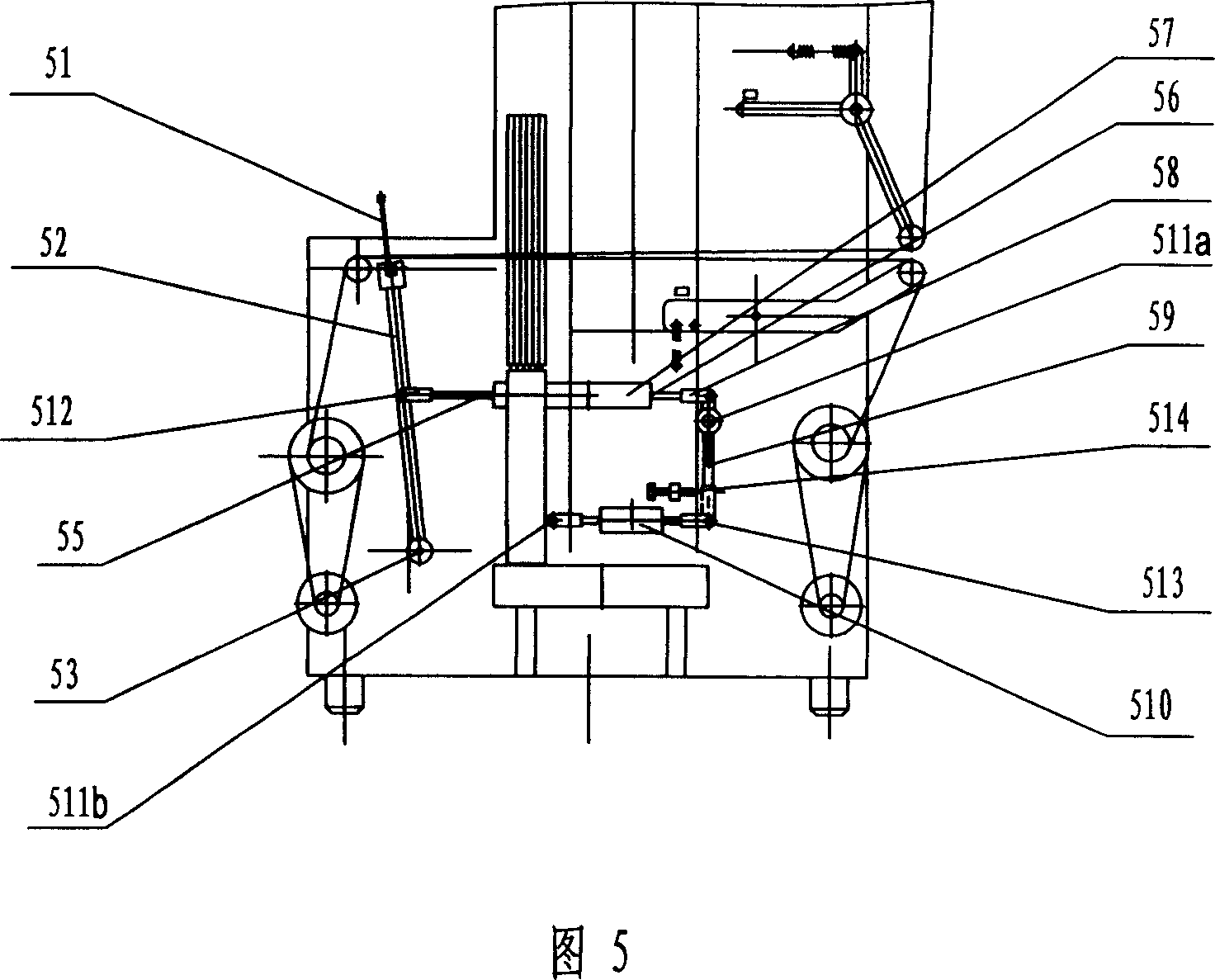

[0017] 1-left wallboard, 2-let-off mechanism, 3-coiling mechanism, 4-weft insertion mechanism, 5-beating-up mechanism, 6-opening mechanism, 7-electric control box, 8-right wallboard, 21-top Warp sensor, 22-bottom warp sensor, 23-fluffing swing arm, 24-up warp feed beam, 25-bottom warp beam, 26-rear shaft roller, 27-back beam swing arm, 28-top warp feed motor, 29- Synchronous belt, 210-let-off servo motor, 211-upper swing arm spring, 31-optical axis of front chest beam, 32-cloth roll, 33-take-up servo motor, 41-pneumatic weft inserter, 42-piston rod , 43-rapier head, 44-piston rod, 45-weft selection cylinder, 46-release cylinder, 47-weft cutter, 48-color rod for weft selection, 49-porcelain eye for weft insertion, 51-movable reed, 52-sley, 53-sley bar, 55-connecting rod, 56-piston rod, 57-beating-up cylinder, 58-fixed rod, 59-movable rocker arm, 510-raising cylinder, 511a-fixed pin, 511b-fixed pin, 512, 513-spherical joint bearing, 514-positioning screw, 61-electronic jacquard...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap