Modified catalyst supports

A catalyst carrier and catalyst technology, applied in molecular sieve catalysts, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of high solvent cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

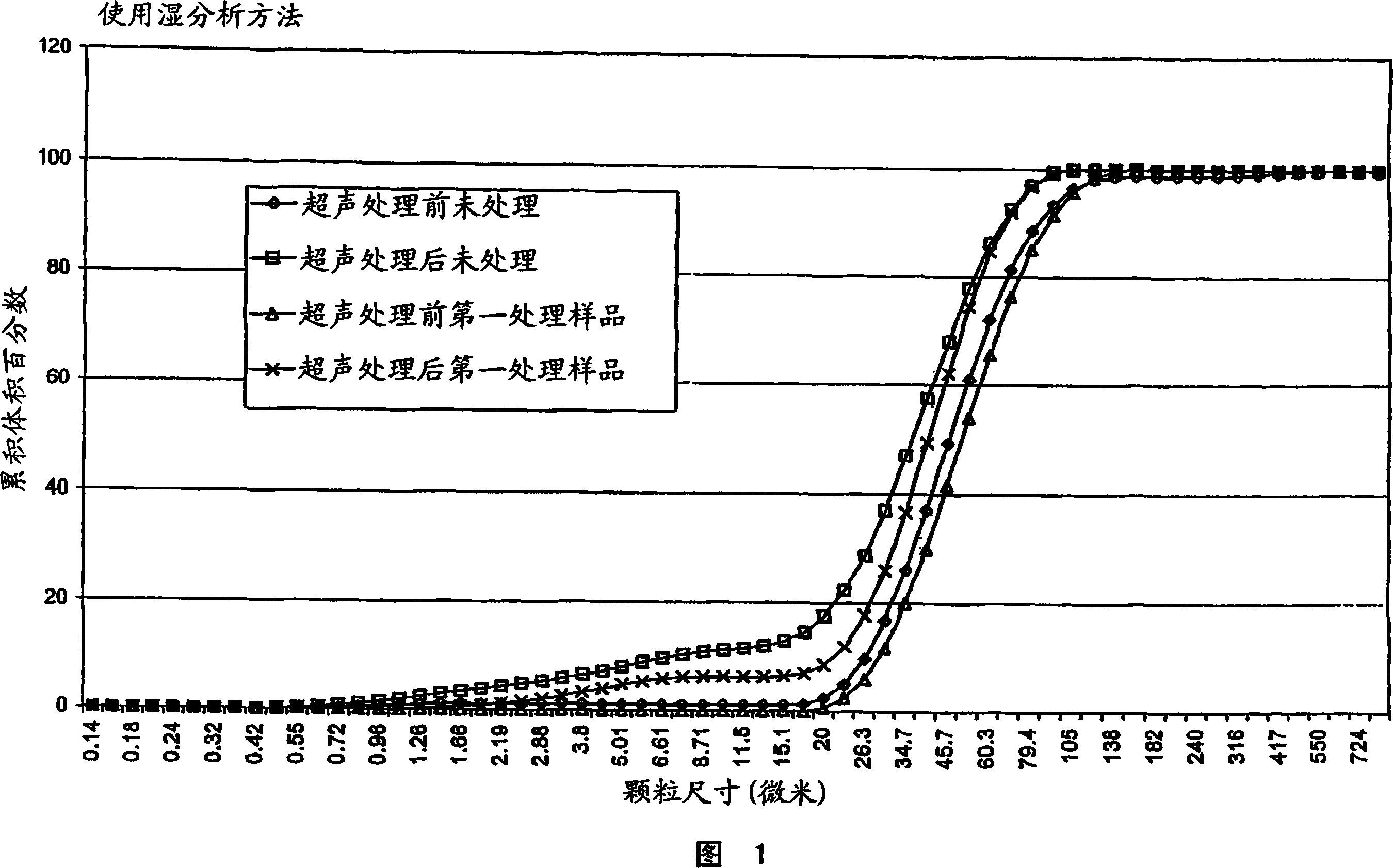

[0046] The preparation of embodiment 1-catalyst sample 1

[0047] The MSA reagent solution was prepared as follows: 94.9 g of TEOS was quickly added to 4 L of acidified demineralized water with vigorous stirring. Add enough HNO to the water 3 , so that the pH value reaches 2.2 to 2.5, and kept at 3°C to 8°C. Fifteen minutes after the addition of TEOS, an aliquot was removed and tested for the rate of color change. Over 90% of total color developed within 5 minutes. In another stirred heating vessel, a slurry of alumina support containing 640 g of alumina suspended in 2 L of demineralized water was heated. MSA reagent was added thereto at a rate of 35ml / min, and the slurry was kept at 50±5°C during the whole process of adding MSA. After the addition of the MSA reagent, the slurry was stirred and kept at 50±5°C until more than 95% of the silicon had reacted with the alumina. Once the reaction is complete, the stirring is stopped, the solids are allowed to settle, and the ...

Embodiment 2

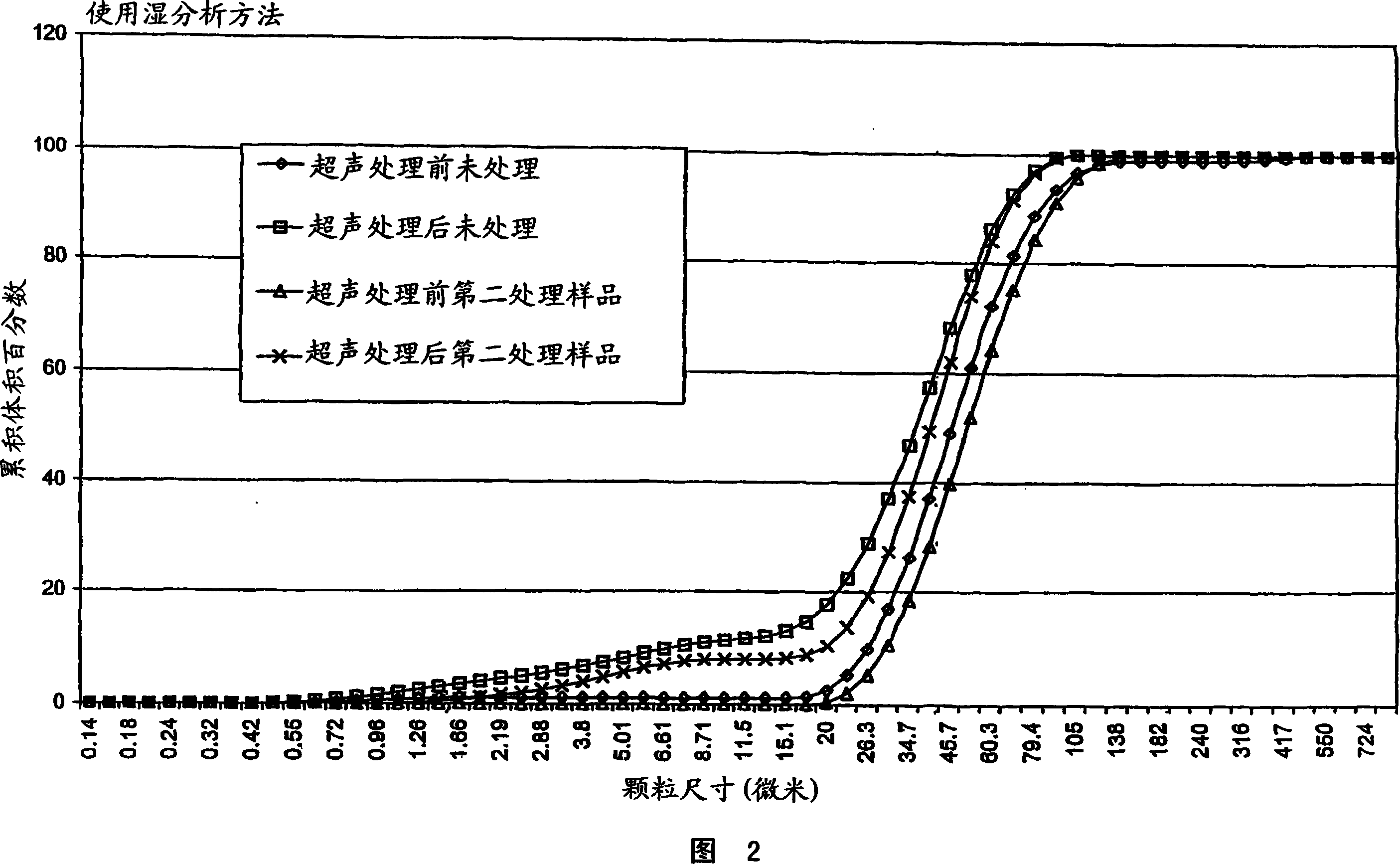

[0049] The preparation of embodiment 2-catalyst sample 2

[0050] The MSA reagent solution was prepared as follows: 73.6 g of TEOS was quickly added to 667 mL of acidified demineralized water under vigorous stirring. Add enough HNO to the water 3 , so that the pH value reaches 2.2 to 2.5, and kept at 3°C to 8°C. Fifteen minutes after the addition of TEOS, an aliquot was removed and tested for the rate of color change. Over 90% of total color developed within 5 minutes. In another stirred heating vessel, a slurry of alumina support containing 100 g of alumina suspended in 333 mL of demineralized water was heated. MSA reagent was added thereto at a rate of 5 ml / min, and the slurry was kept at 50±5°C during the whole process of adding MSA. After the addition of the MSA reagent, the slurry was stirred and kept at 50±5°C until more than 95% of the silicon had reacted with the alumina. Once the reaction is complete, the stirring is stopped, the solids are allowed to settle, a...

Embodiment 3

[0052] The preparation of embodiment 3-catalyst sample 3

[0053] The MSA reagent solution was prepared as follows: 94.9 g of TEOS was quickly added to 4 L of acidified demineralized water with vigorous stirring. Add enough HNO to the water 3 , so that the pH value reaches 2.2 to 2.5, and kept at 3°C to 8°C. Fifteen minutes after the addition of TEOS, an aliquot was removed and tested for the rate of color change. Over 90% of total color developed within 5 minutes. A slurry containing 640 g of alumina suspended in 2 L of demineralized water was added to the MSA. The mixture was then maintained at 50±5°C. The mixture was stirred and maintained at 50±5°C until more than 95% of the silicon had reacted with the alumina. Once the reaction is complete, the stirring is stopped, the solids are allowed to settle, and the clear mother liquor is decanted from the vessel. The remaining thick slurry was vacuum filtered to remove residual solution. Spread the filtered solid on a dryi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com