Vehicle lamp inspection equipment and inspection method

A technology of car lights and inspection devices, which is applied in the direction of testing the alignment of automobile headlights, measuring devices, instruments, etc., can solve problems such as displacement, and achieve the effect of cheap construction, wide application, and rapid inspection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

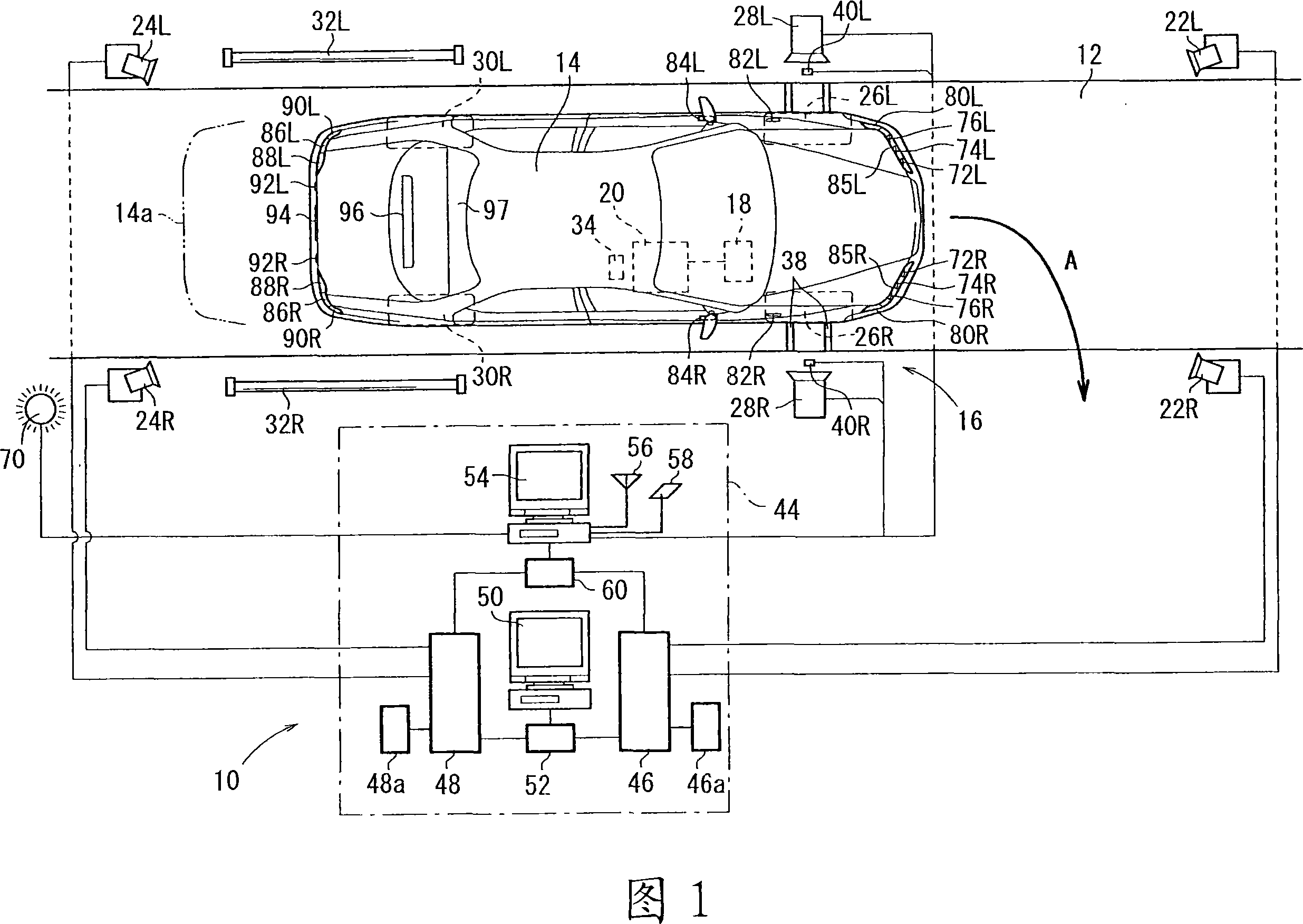

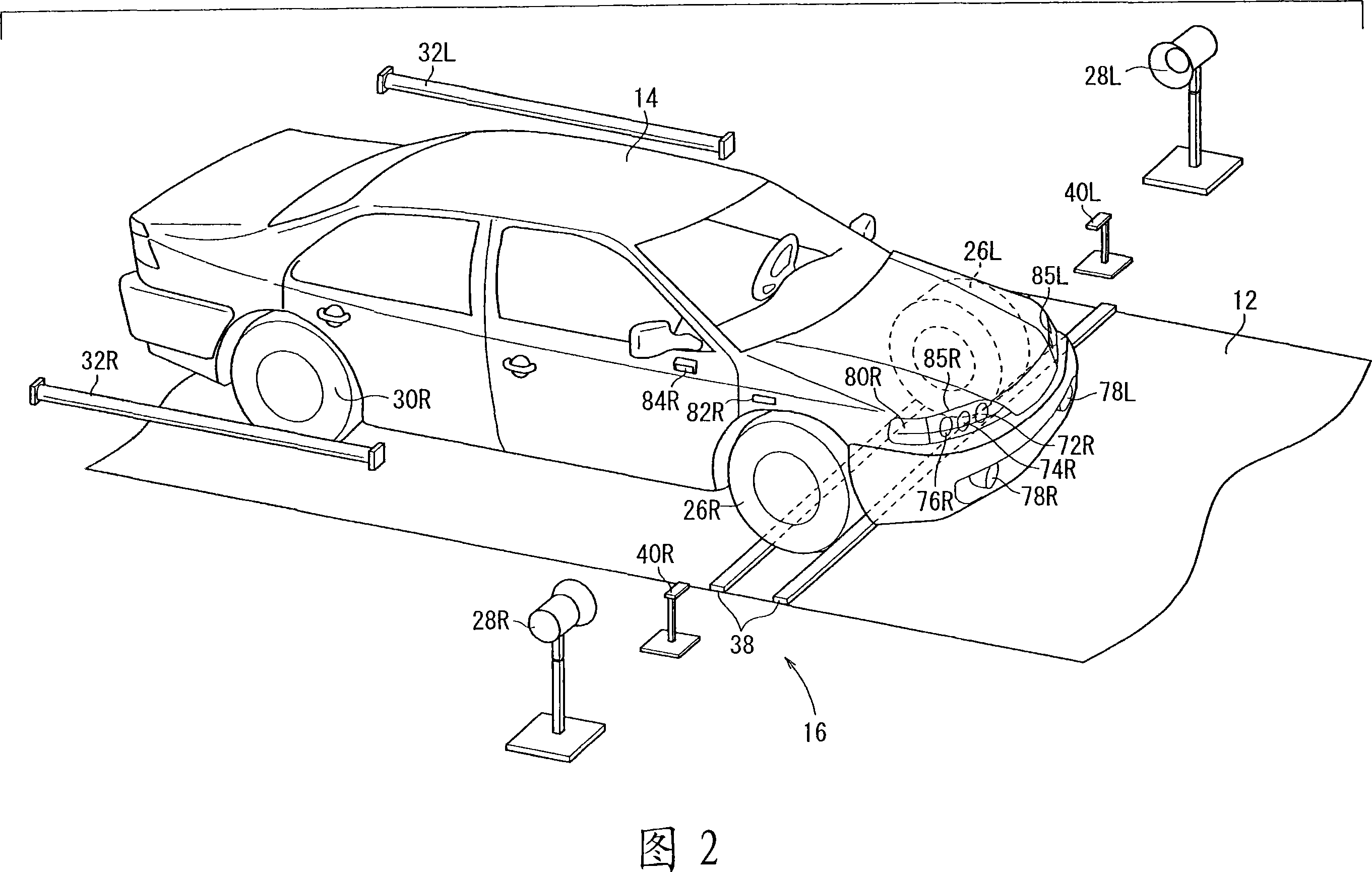

[0062] Next, a vehicle lamp inspection device according to an embodiment of the present invention will be described with reference to FIGS. 1 to 15 . In the lamp inspection device 10 and the vehicle 14 , mechanisms provided one on the left and one on the left and right are distinguished from each other by "L" added to the numerals assigned to the left mechanism and "R" added to the numerals assigned to the right mechanism.

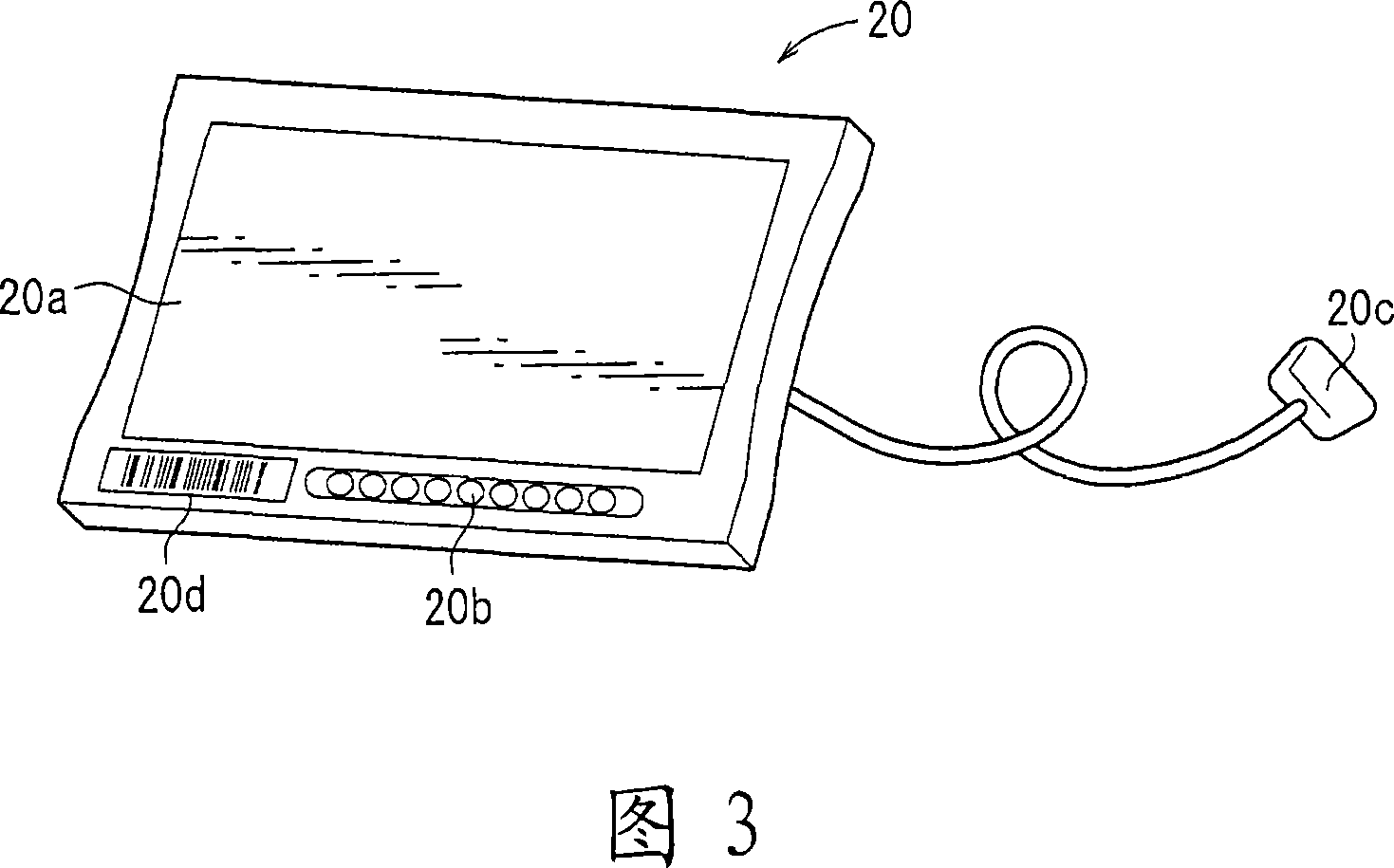

[0063] As shown in FIG. 1 , a vehicle lamp inspection device 10 according to the present embodiment is a device for inspecting various lamps of a vehicle 14 driven into a track 12 by an inspector. The vehicle lamp inspection device 10 has: a vehicle position recognition unit 16 for detecting when the vehicle 14 arrives and stops at a prescribed inspection position; a terminal unit 20 connected to an ECU (Electronic Control Unit) 18 mounted on the vehicle 14; Cameras (image capture devices) 22L, 22R for capturing images of lamps on the vehicle 14 that have ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com