Double-layer bushing straight-line flexuosity restriction support with transverse diaphragm

A double-layer casing, buckling restraint technology, applied in building components, anti-vibration and other directions, can solve the problems of high cost, limited material selection, cumbersome manufacturing and installation, etc., to achieve cost savings, convenient long-distance transportation, and improve installation accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

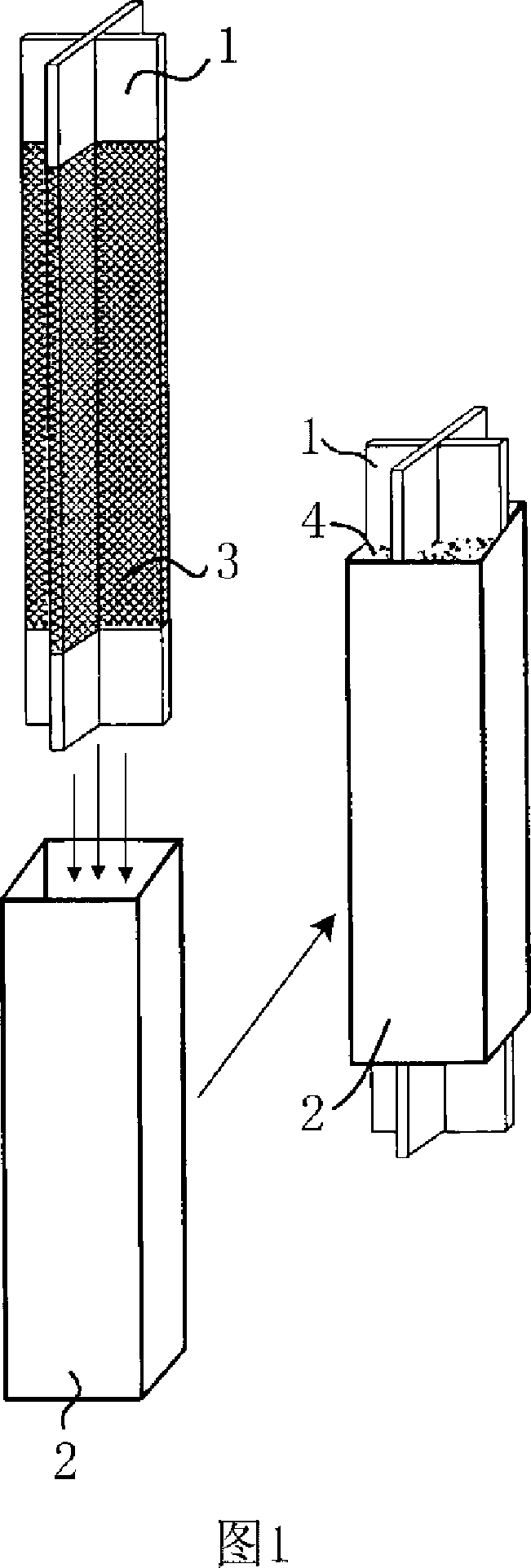

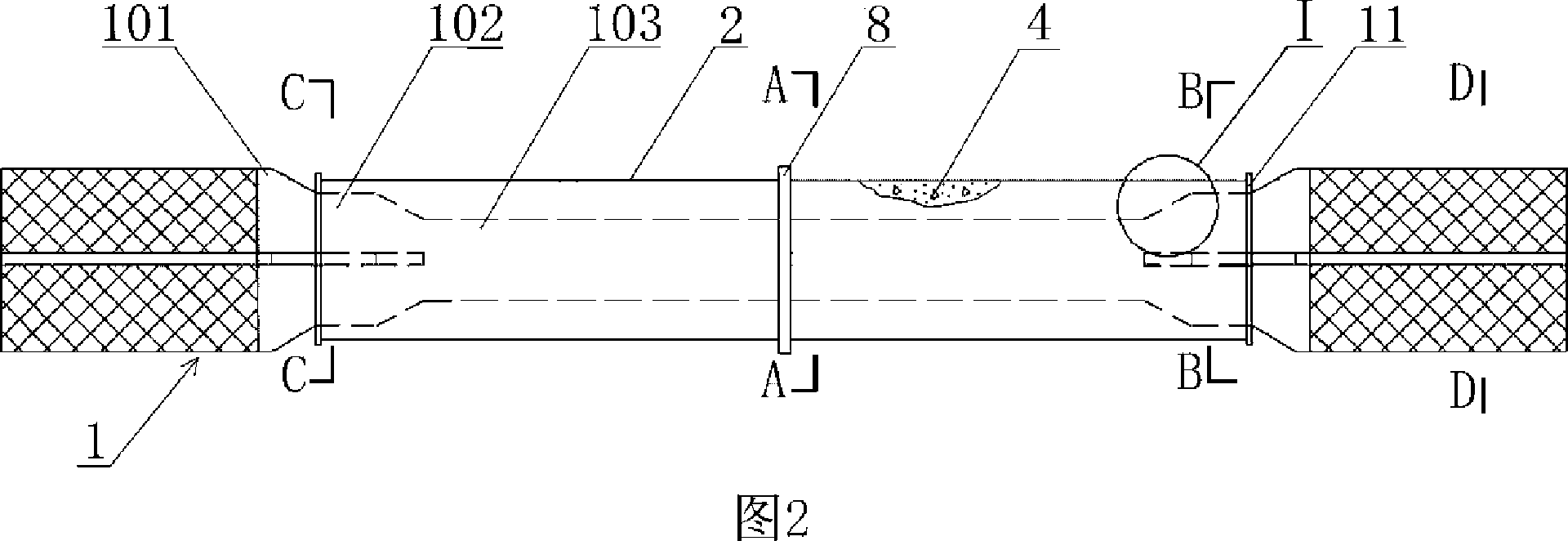

[0048] Referring to FIG. 2 , this cross-shaped buckling-restrained brace with a double-layer casing with a diaphragm includes a core steel brace 1 and a steel jacket restraint steel pipe 2 . The above-mentioned jacket restraint steel pipe 2 is divided into two sections, which are respectively set on the outer side of the core steel support 1 and located on both sides of the diaphragm 8 .

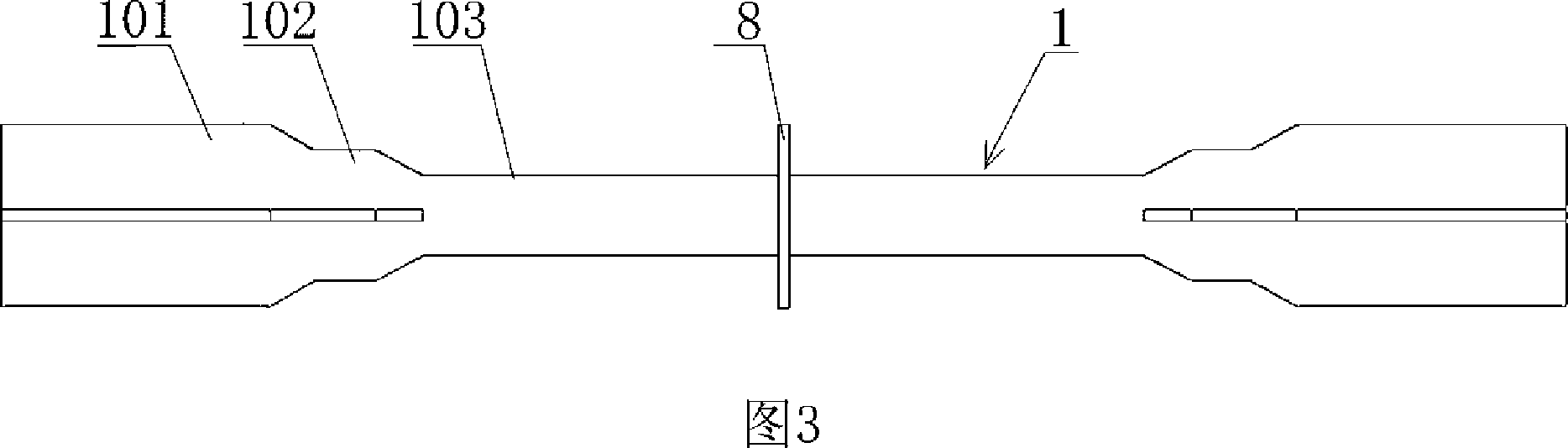

[0049] Referring to Fig. 3-7, the above-mentioned core steel support 1 is along its axial direction. Between them is the transition section 102, the cross section of the yield section 103 is in-line shape, the cross section of the transition section 102 and the overhanging section 101 is cross-shaped, and a radial diaphragm 8 is welded in the middle of the yield section 103 , a reserved hole 10 is provided on the diaphragm.

[0050] Between the jacket restraining steel pipe 2 and the core steel support 1, it is located outside the yield section 103 and the transition section 102 of the core...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com