Device for fixing a flat object, in particular a substrate, to a work surface by means of low pressure

A technology for fixing a plane and a working surface, which is applied in the field of substrate devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

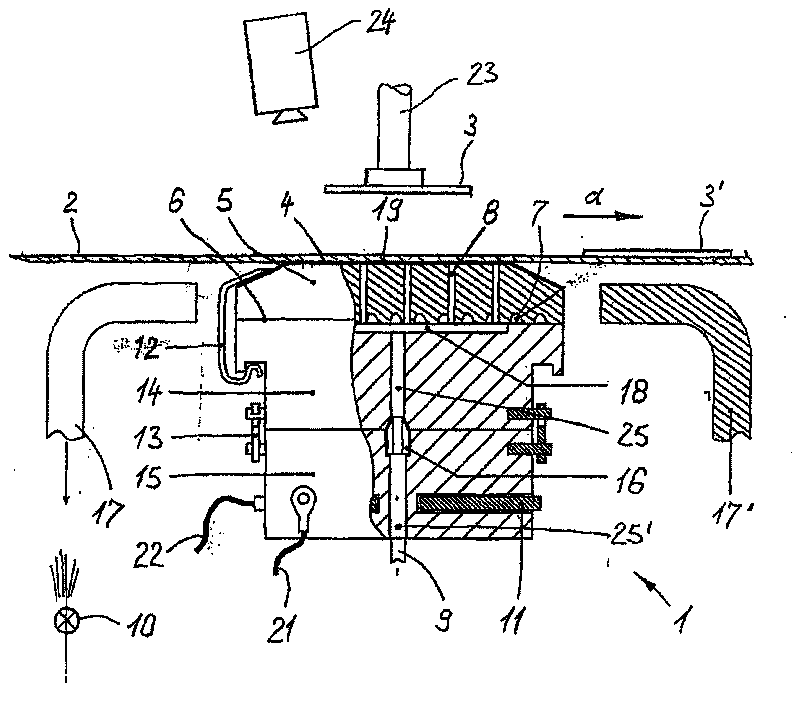

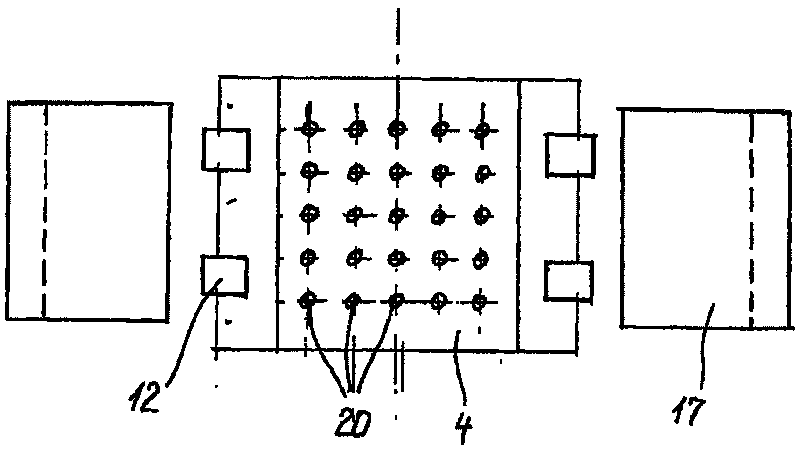

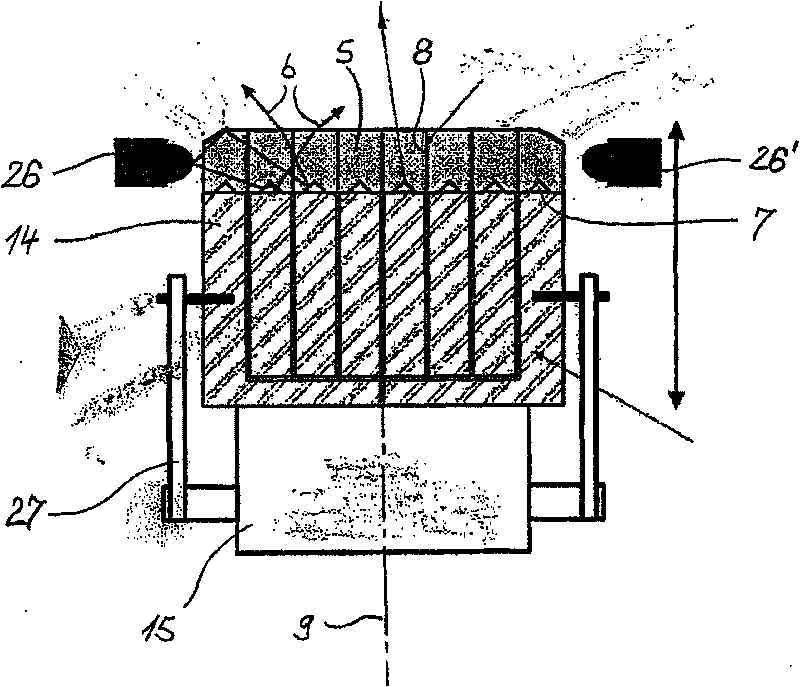

[0020] as by figure 1 and figure 2 It can be seen that the device generally marked with 1 mainly consists of a support plate 5 , for example made of glass and other transparent or partially transparent materials. The carrier plate has an approximately rectangular plane with a working surface 4 which can be provided, for example, with an electrically conductive layer 19 . The support plate 5 is slightly inclined on both long sides. This inclination facilitates the introduction or removal of the substrate which moves linearly in the direction of the arrow a. A light-reflecting structure 7 having a plurality of bowl-shaped pits is arranged on the back side 6 of the support plate 5 . Furthermore, the support plate is penetrated by a plurality of vacuum channels 8 , which terminate at holes 20 in the working surface 4 .

[0021] The carrier plate 5 rests on a plate base 14 and is detachably connected thereto by means of clamping elements 12 . The clamping part made of metal u...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap