Method for manufacturing knitwear

A technology of knitting and weaving, applied in the directions of knitting, weft knitting, warp knitting, etc., can solve the problem of high cost, achieve the effect of fine opening degree and increase the pattern formation scheme

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

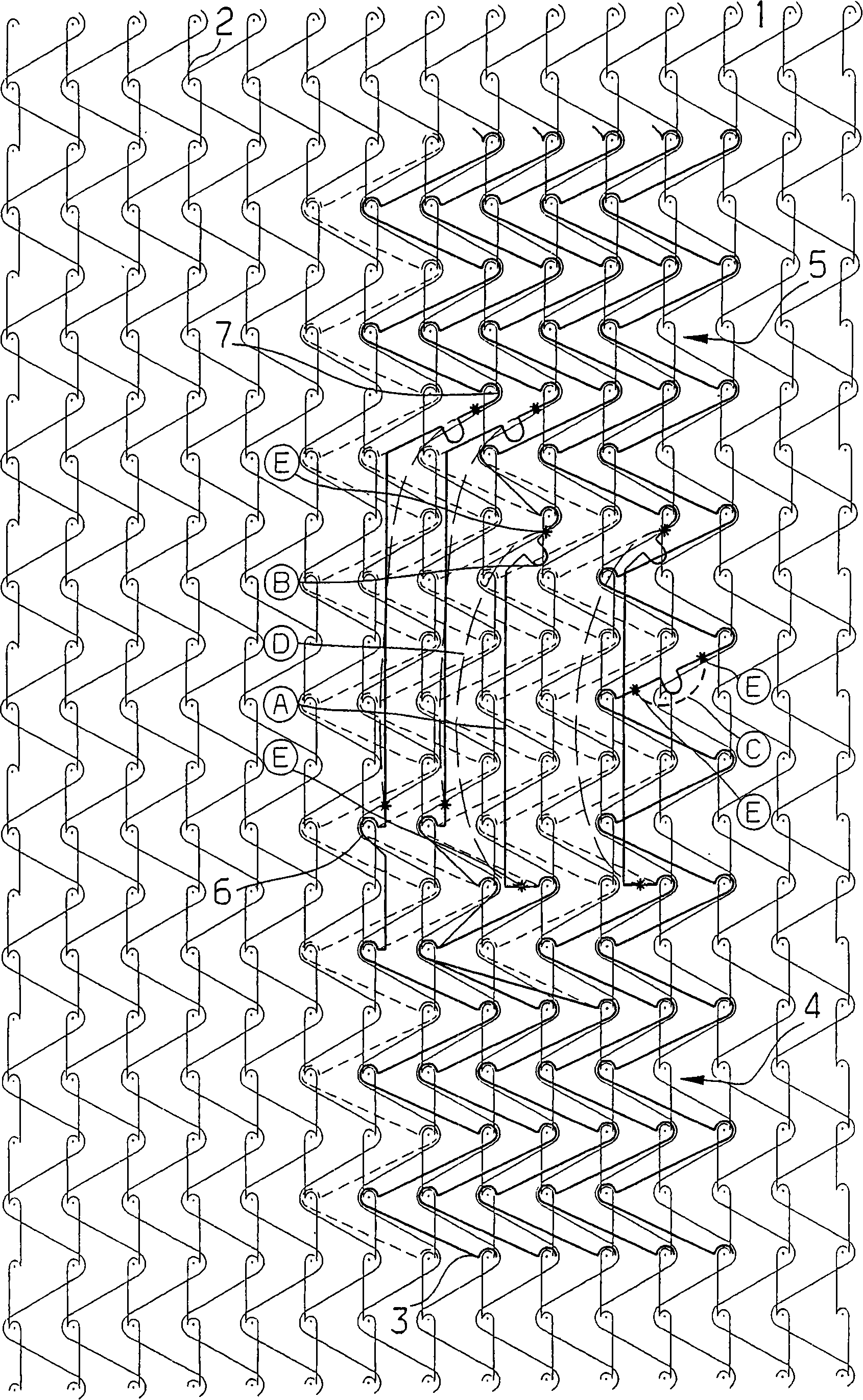

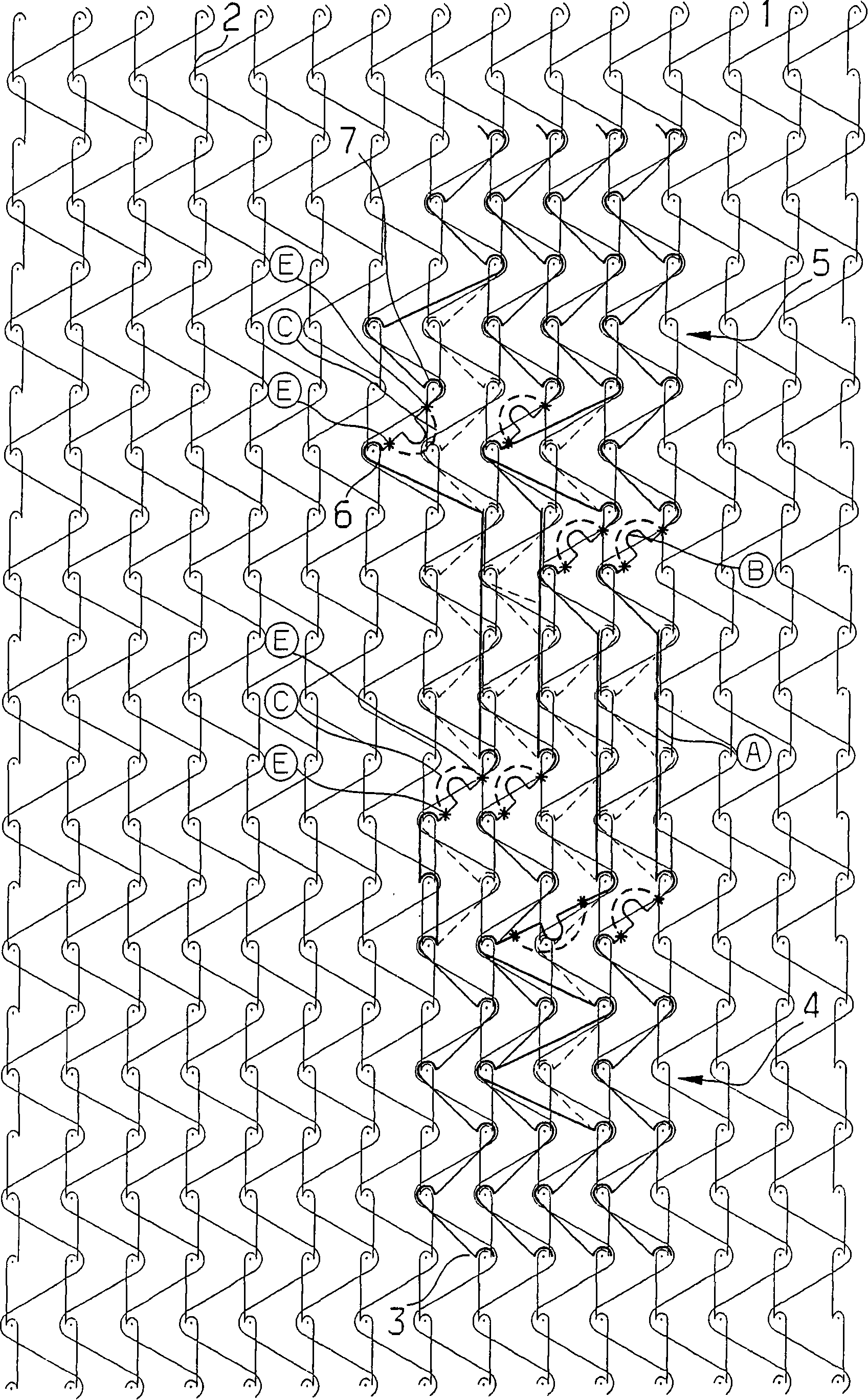

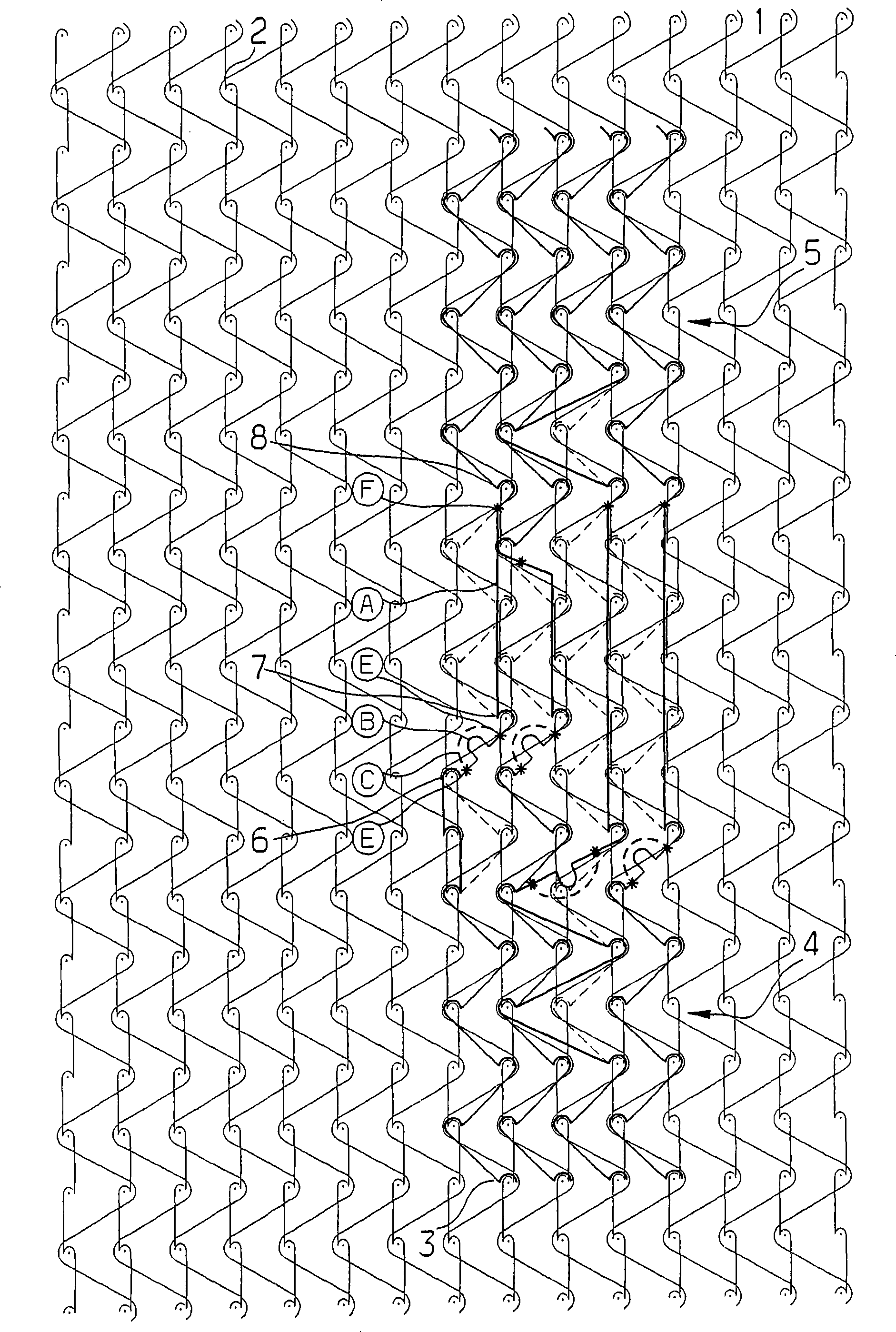

[0019] figure 1 Shown is a knitwear 1 with a base fabric 2 formed by chain-laying. For the manufacture of this base fabric two basic bars are used which work with the following laying movement needles:

[0020] GB 1: 1-0 / 0-1

[0021] GB 2: 0-0 / 2-2

[0022] When the base fabric 2 is manufactured, a plurality of jacquard threads are woven together to form the pattern 4, 5, and the pattern 4, 5 follows each other at a certain distance in the production direction of the knitted fabric. The pattern 4, 5 is carried out with a ground laying motion of the jacquard-bar in an open or closed structure as loops or tucks at half or full gauges, such as in tricot or woven fabrics Laying. Some flower patterns can also be produced by borrowing simple flower bars without using jacquard-bars.

[0023] After the pattern 4 has been laid, the jacquard thread 3 is not subjected to any lapping and is skipped (section A). This is accomplished by a well-known reverse displacement ( ) is realiz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com