Machine body of electronic device

A technology for electronic devices and bodies, applied in the direction of electrical equipment casings/cabinets/drawers, electrical components, etc., can solve problems such as the breakage of tenons 130, affecting the assembly quality of the body 100, the appearance of electronic devices, and reducing the structural reliability of the body 100, etc., to achieve The best structural reliability, the improvement of poor assembly quality, and the effect of good assembly quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

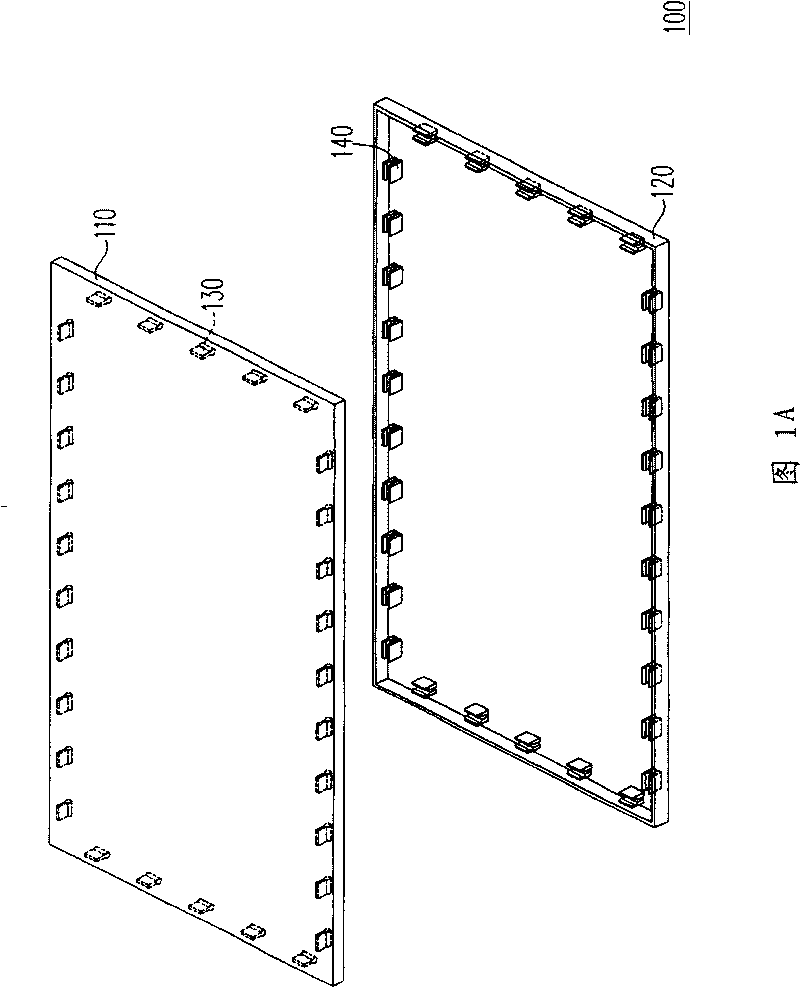

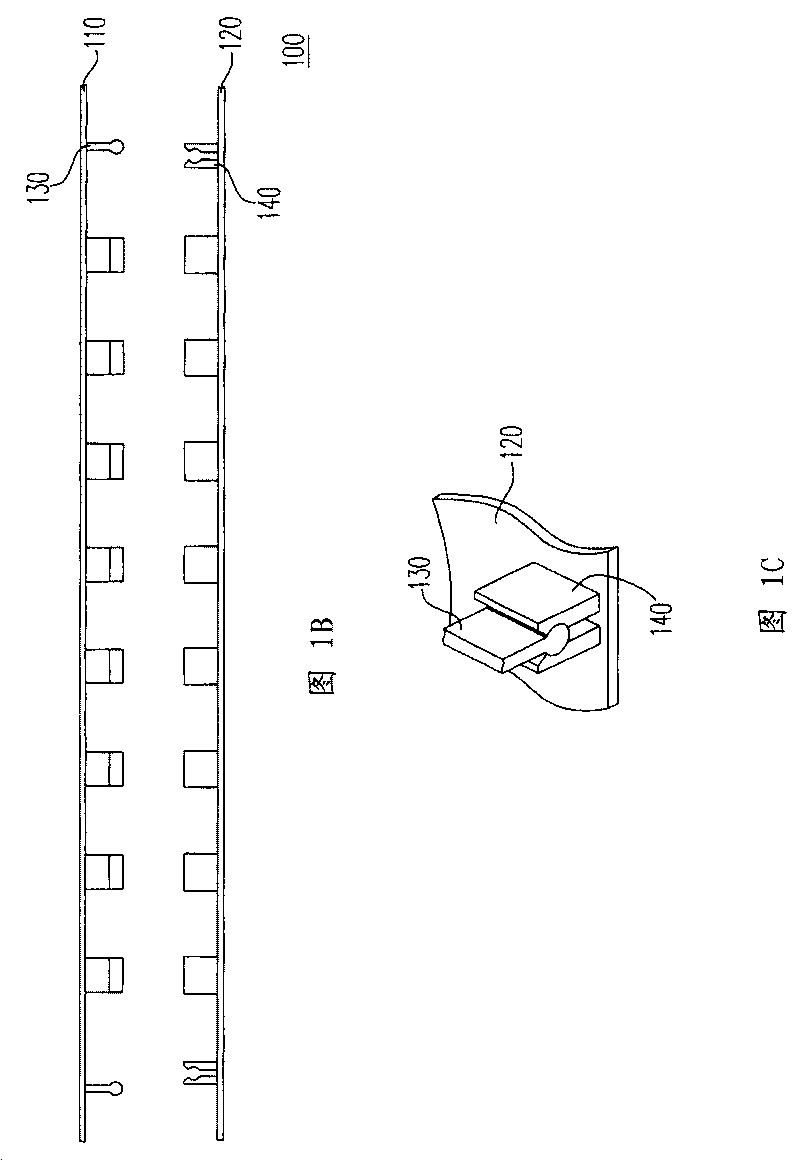

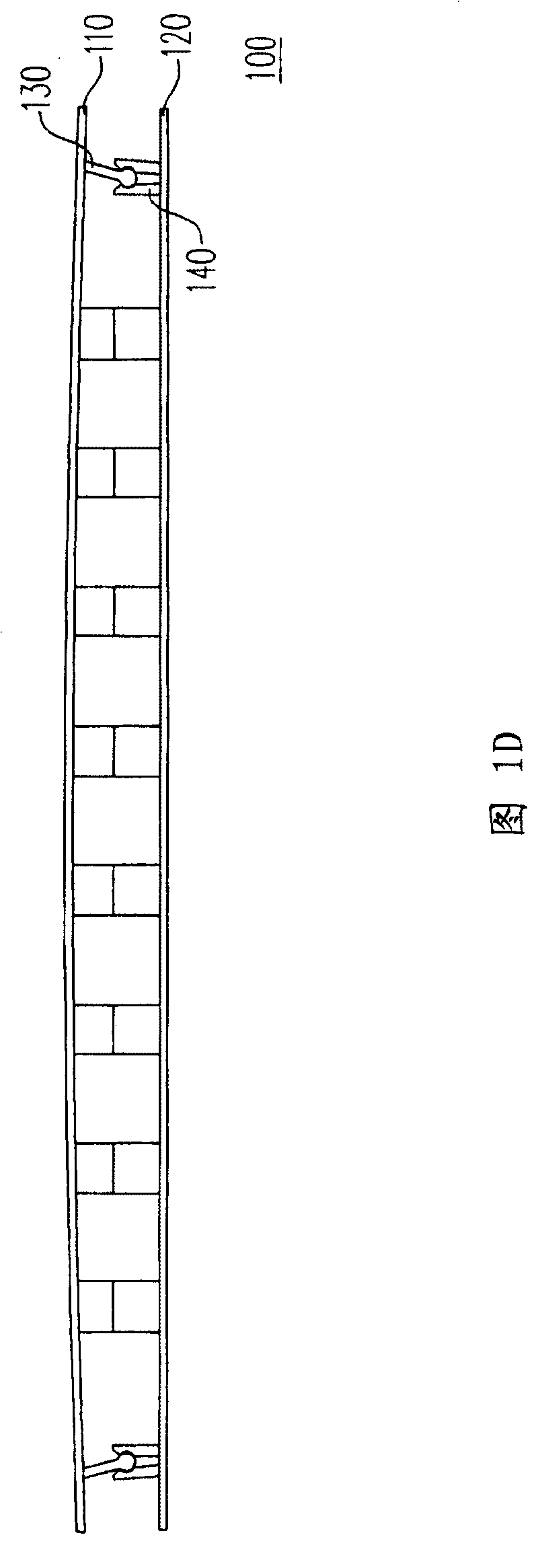

[0026] Figure 2A Shown is an exploded view of the body of an electronic device according to a preferred embodiment of the present invention, Figure 2B shown as Figure 2A side view of the body. Please also refer to Figure 2A and Figure 2B , the body 200 of this embodiment is a body of an electronic device, and the electronic device is, for example, a portable electronic device. In this embodiment, the electronic device is a notebook computer. The body 200 includes a first housing 210 , a plurality of tenon sets 220 , a second housing 230 , and a socket 240 corresponding to the plurality of tenon sets 220 . In this embodiment, the tenon set 220 is integrally formed with the first housing 210 , and the socket 240 is integrally formed with the second housing 230 , for example. In this embodiment, the first housing 210 is, for example, the upper cover of the electronic device, the second housing 230 is, for example, the lower cover of the electronic device, and the second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com