Sealing device

A sealing device and sealing element technology, applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve the problems of uneven compression, easy leakage, loss of elasticity, etc., and achieve good sealing effect and clean and tidy equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

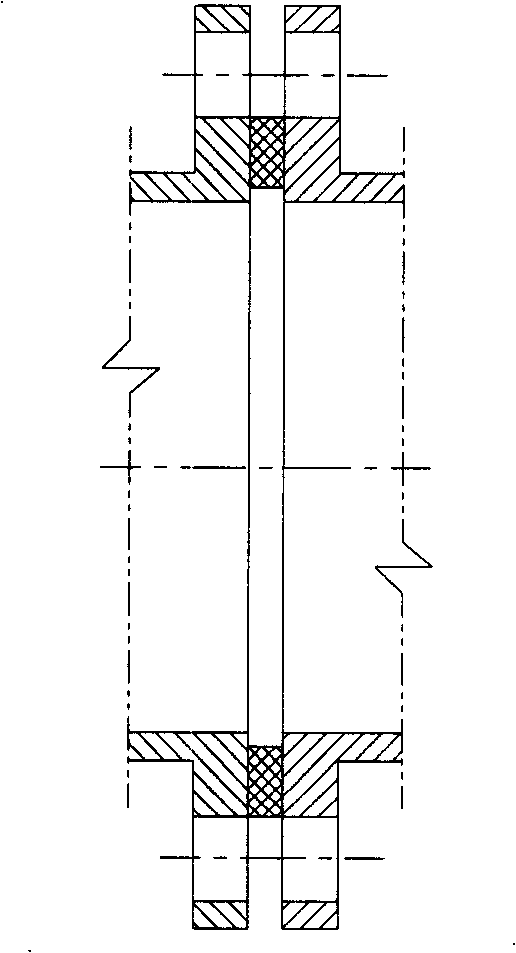

[0072] Such as Figure 4 to Figure 8 As shown, this embodiment uses the pressure of the extruded pressurized sealing ring itself and the radial elastic force of the elastic retaining ring to seal. It is mainly composed of inner and outer retaining rings and sealing rings. One of the inner and outer retaining rings is elastic. Yes, it can expand and contract when stressed, and one of the inner and outer retaining rings can be set to be elastic as required. exist Figure 4 to Figure 8 In the two cases of this method, Image 6 It is the property that the elastic ring 103 is outside, Figure 7 It is the situation that the elastic ring 105 is inside. The fixed-force inner retaining ring 101, the pressurized sealing ring 102, the elastic outer retaining ring 103, etc. are all annular. Their assembly, connection relationship, and the realization of the principle of action and purpose are as follows:

[0073] The pressure-inflating sealing ring 102 is a hollow ring like a bicycle...

Embodiment 2

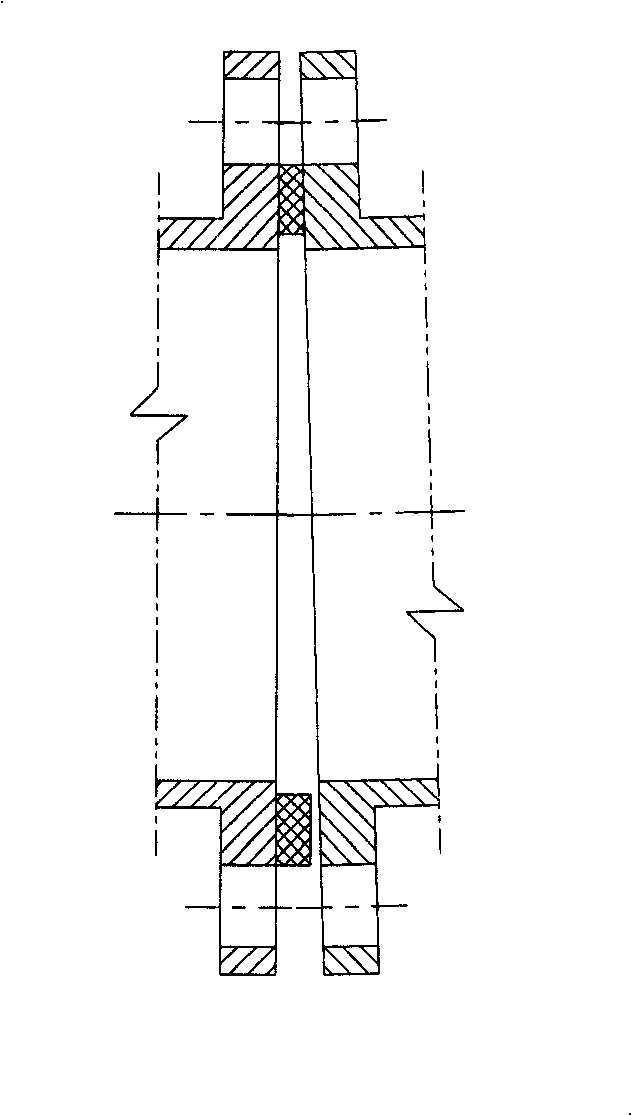

[0077] Such as Figure 9 to Figure 13 As shown, this embodiment uses the pressure of the extruded pressure-filled sealing ring itself and the axial elastic force of the butterfly spring to seal. It is also mainly composed of inner and outer retaining rings and a pressure-filled sealing ring. The difference from Embodiment 1 The outer (or inner) retaining ring of this embodiment is composed of dynamic and static parts, and a butterfly spring is added to the dynamic retaining ring, so that the dynamic and static retaining ring can be set as the outer retaining ring, Such as Figure 11 as shown; it is also possible to set the dynamic and static retaining rings as inner retaining rings, such as Figure 12 shown.

[0078] by Figure 11 and Figure 9 , Figure 10 , Figure 13 For example, the pressure sealing ring 202 is installed between the inner retaining ring 201, the static outer ring 203, and the moving outer ring 204. The pressure sealing ring 202 is a hollow ring like ...

Embodiment 3

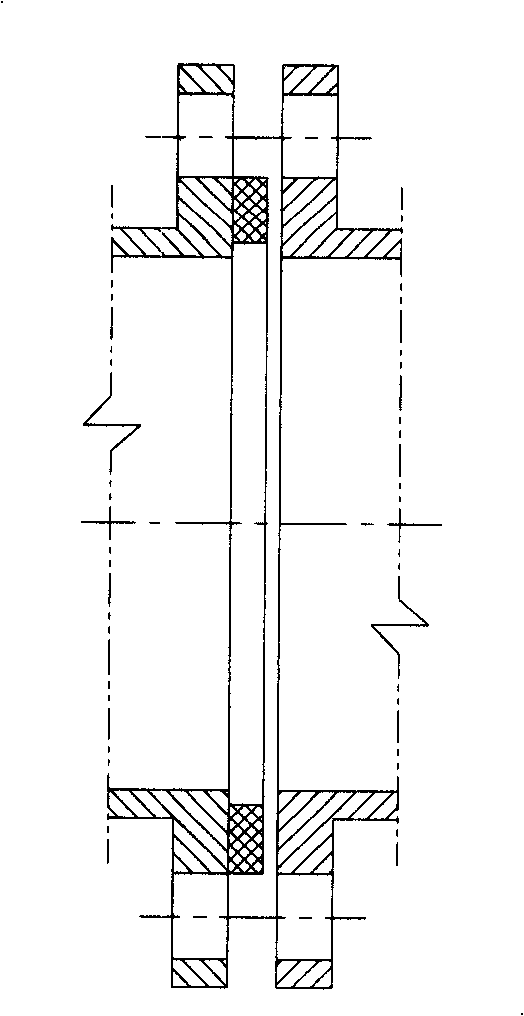

[0081] Such as Figure 14 to Figure 18 As shown, in this embodiment, the whole gasket is firstly installed between the two flanges, and after the fastening is completed, the pressure is charged, and after the pressure is charged, it is sealed. Can be filled with compressible pressurized fluid medium.

[0082] The pressure charging sealing ring 502 is installed between the inner retaining ring 501 and the outer retaining ring 503 , and after the installation and fastening is completed, the pressure charging sealing ring 502 is charged through the pressure charging pipe 504 . Fill the pressure tube 504 with clamp 506 after filling the pressure. The protection tube 505 is set outside the pressure tube 504 and connected with the outer retaining ring. The protection tube 505 is to prevent the pressure tube 504 from being deformed after being pressurized. The function of the positioning gap measuring block 507 is to be sealed on both sides of the fastening When ensuring the axial ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com