Bearing monitoring device

A monitoring device and bearing technology, applied in the direction of bearing assembly, bearing components, shafts and bearings, etc., can solve problems such as bearing condition monitoring, and achieve the effect of preventing the phenomenon of stalling and affecting production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

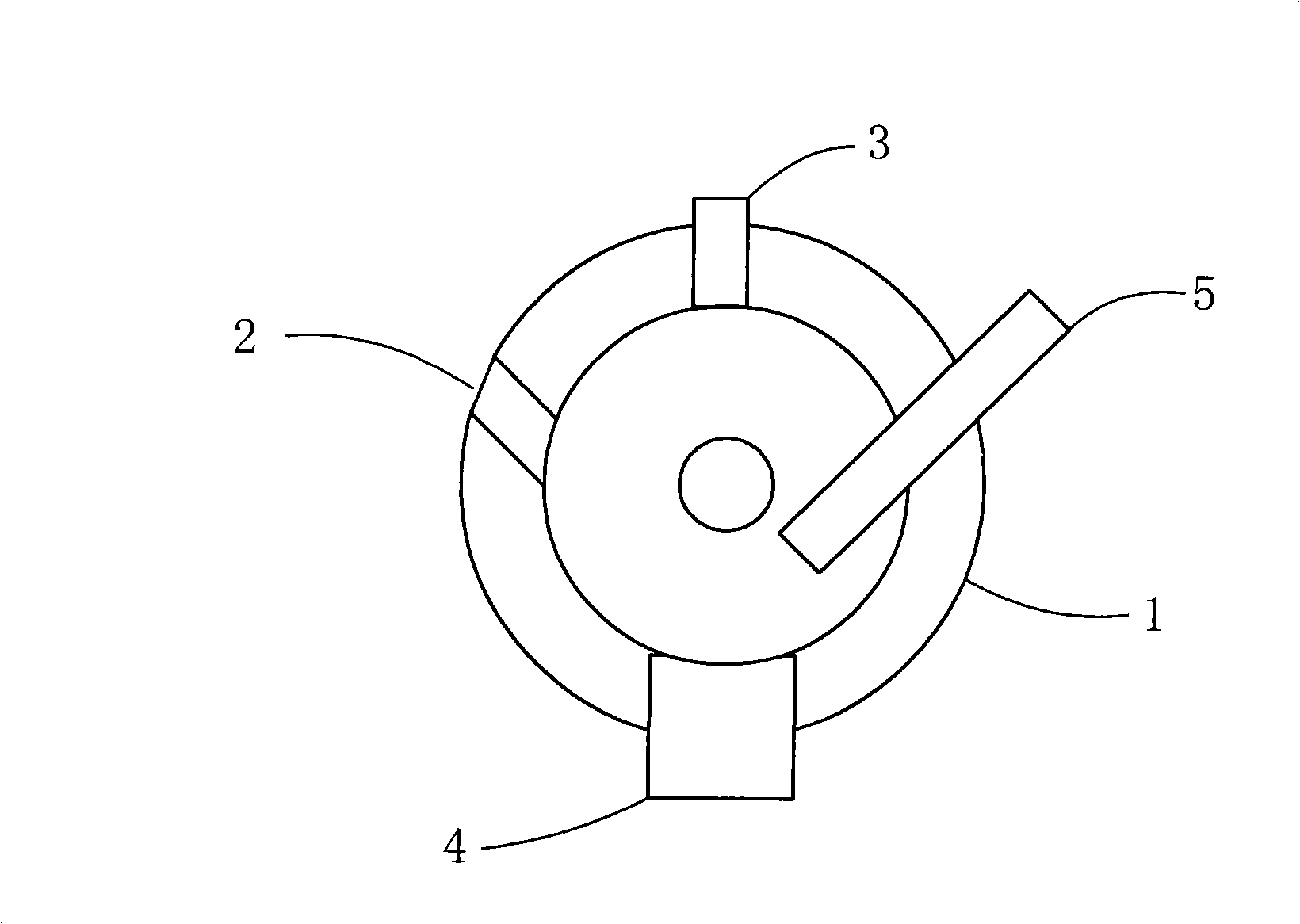

[0012] according to figure 1 As shown, the upper part of the bearing cover 1 is provided with an oil filling port 3, and the lower part is provided with an oil discharge port 4, and observation holes 2 are respectively arranged on both sides of the oblique upper side of the bearing cover, and an endoscope 5 is installed in one side observation hole.

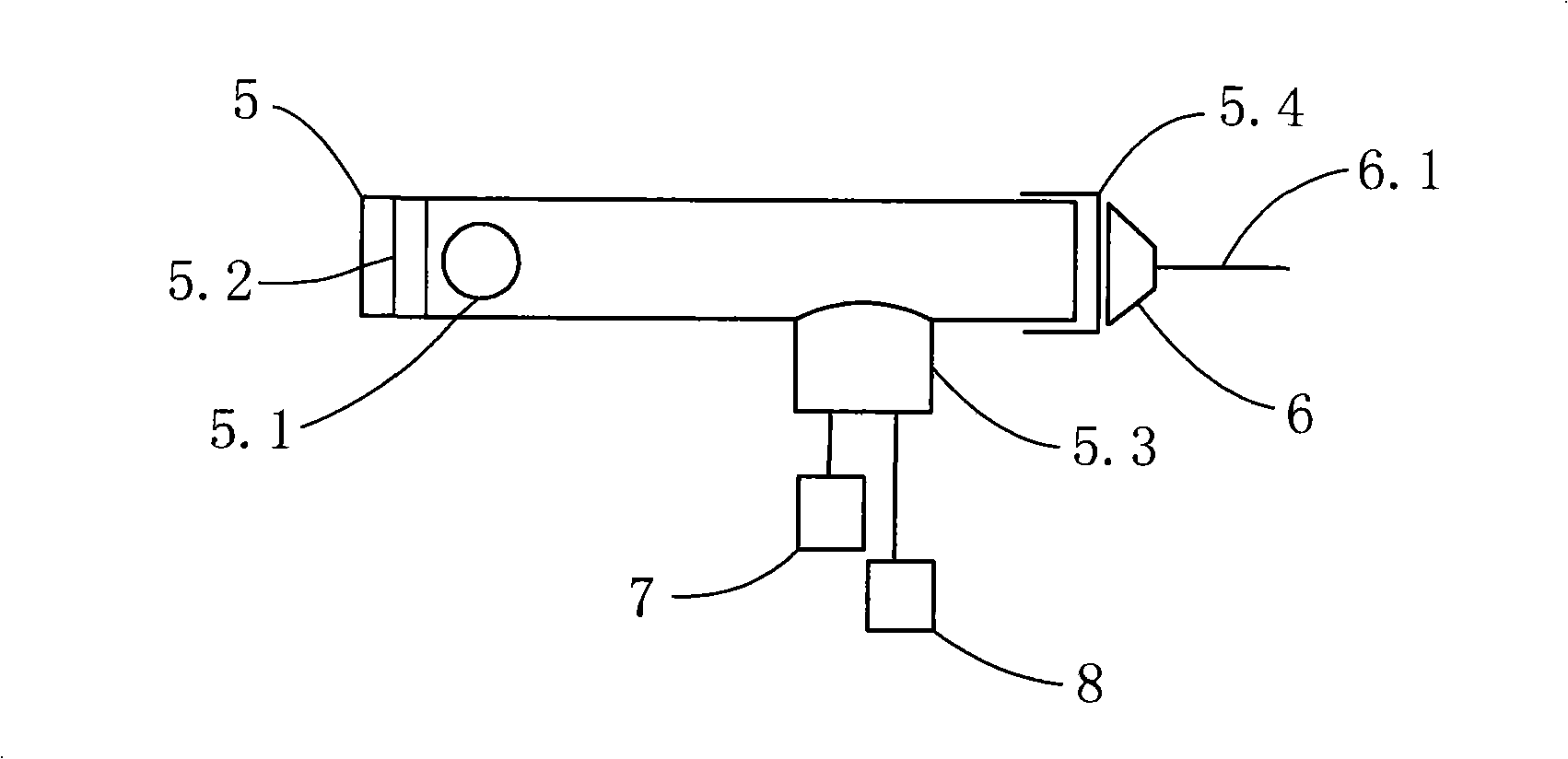

[0013] according to figure 2 As shown, the endoscope has a tubular shell, one end is provided with an inner viewing hole 5.1, a reflector 5.2 is installed on the inner side, a focusing mirror 5.4 is installed at the other end of the tubular shell, and a video head 6 and a video head connecting line 6.1 are installed , on the housing wall between the reflective mirror and the focusing mirror, an illuminating lamp 5.3 is installed, and the illuminating lamp is respectively connected with the constant light source 7 and the frequency light source 8 through an optical fiber.

[0014] The video head connecting line can be connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com