Switching device

A technology for equipment and circuit breakers, applied in the field of opening and closing equipment, can solve the problems of equipment length, reduce the degree of freedom of configuration, and widen the setting space, and achieve the effect of easy transportation, maintenance and repair, and expansion of the degree of freedom of configuration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

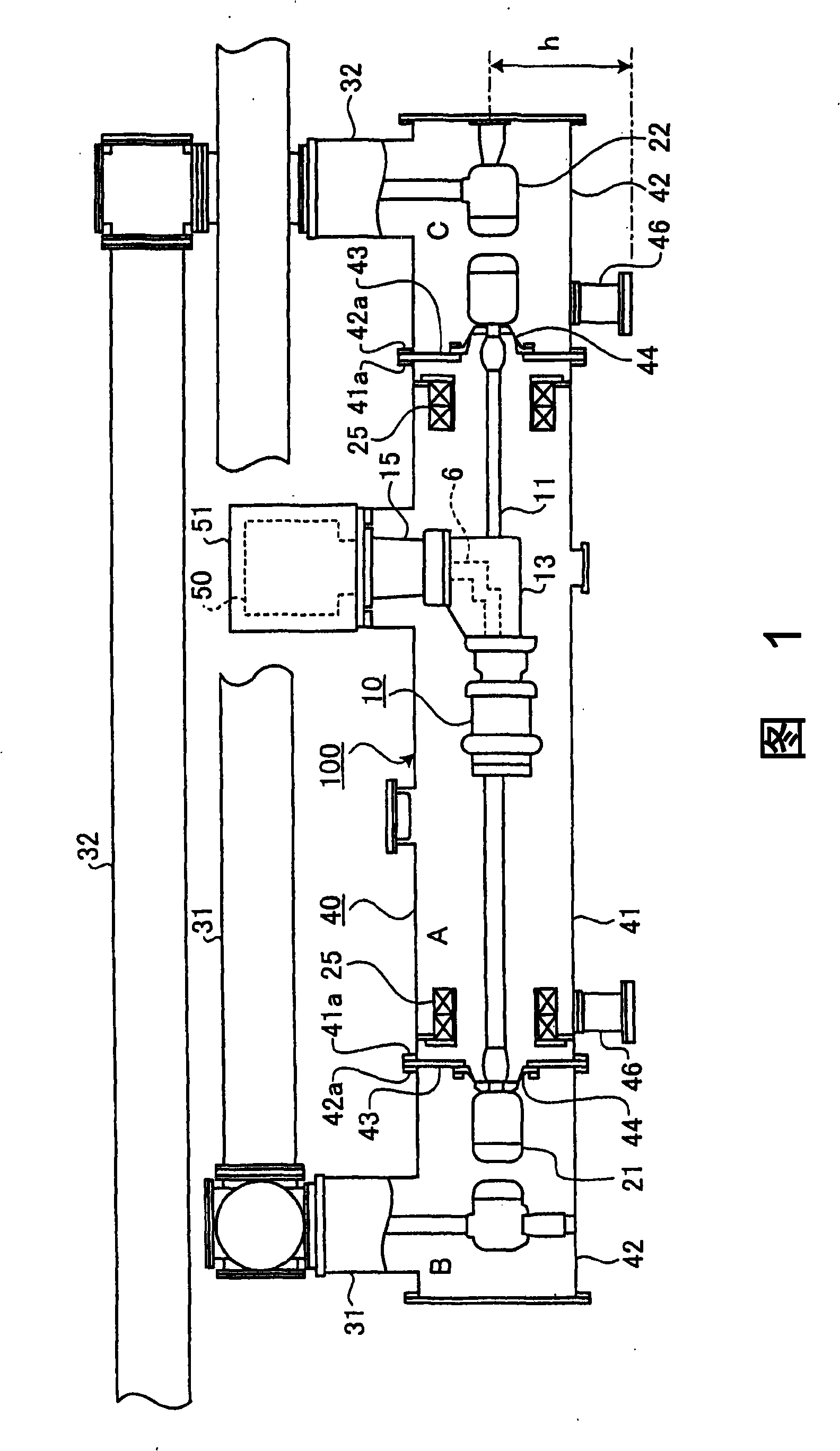

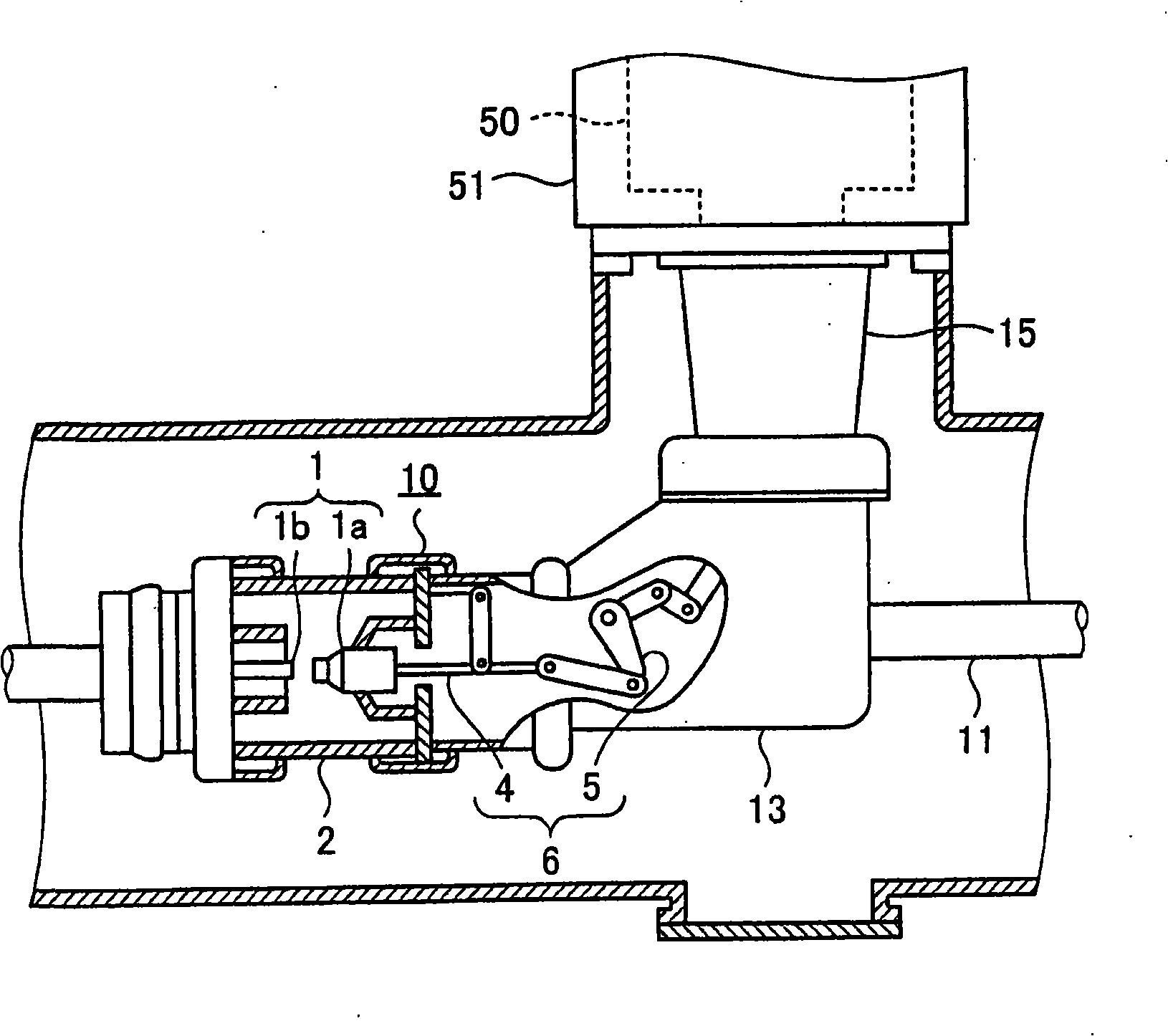

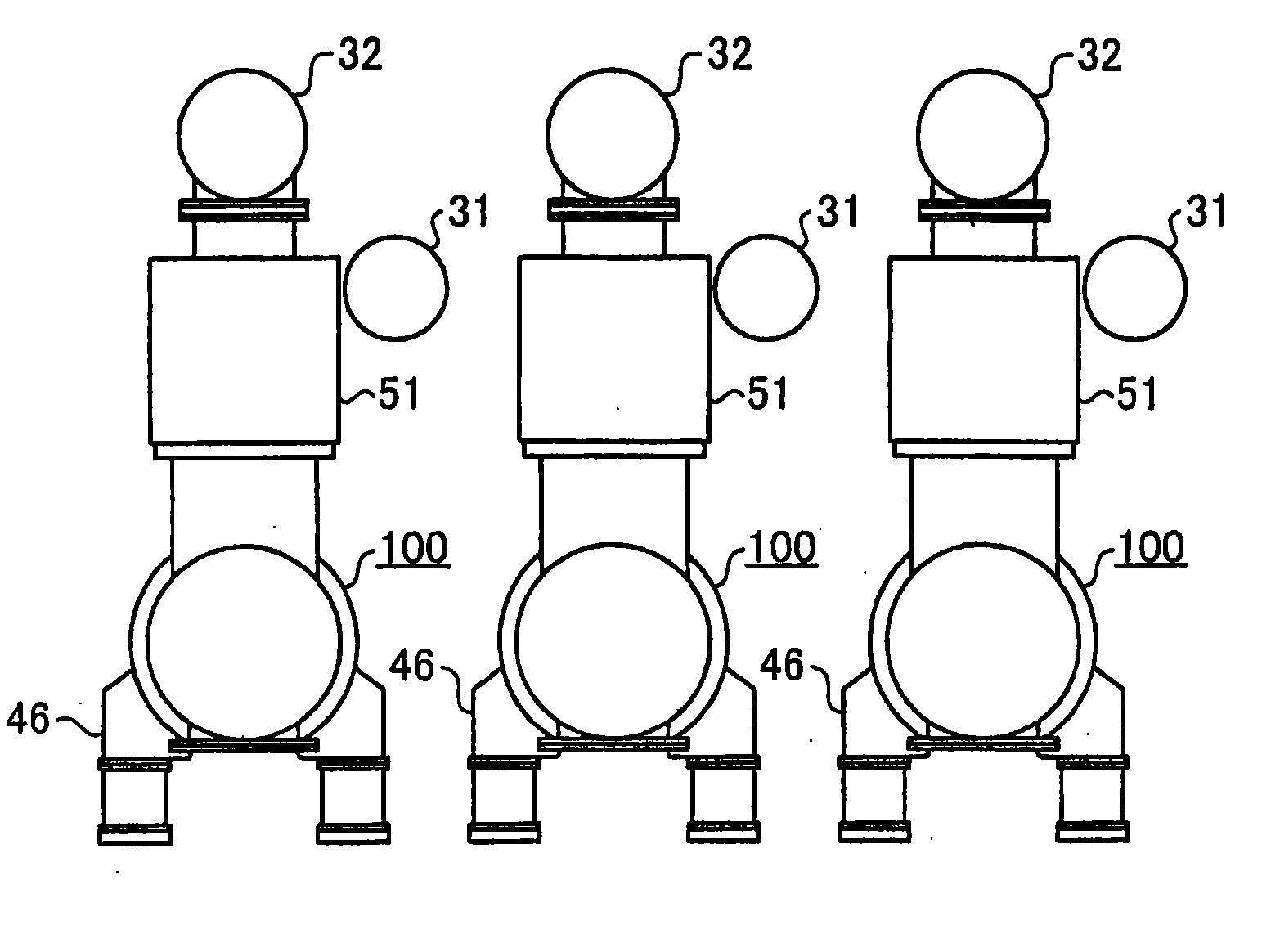

[0037] figure 1 It is a transverse sectional view showing the structure of Embodiment 1 of the switchgear of this invention. figure 2 will be figure 1 An enlarged cross-sectional view of the main part of the switchgear near the breaker is enlarged and cut away. image 3 yes figure 1 Side view of the opening and closing device. Figure 4 yes figure 1 A top view of the switchgear.

[0038] figure 1 Among them, the switchgear 100 includes: a breaker 10 installed in the center of the pressure vessel 40; The circuit breaker 21 and the second circuit breaker 22; the pressure vessel 40 for housing the circuit breaker 10 and the circuit breakers 21, 22; The operating mechanism 50 is accommodated in an operating mechanism case 51 provided on the upper portion of the pressure vessel 40 . The circuit breaker 10 and the operating mechanism 50 are connected by a connection mechanism 6 .

[0039] The pressure vessel 40 is installed at a position raised by a height h from the insta...

Embodiment approach 2

[0050] In the second embodiment, the resistance contact part connected to the resistor is connected in parallel with the main contact part to reduce the pulse at the time of restarting. Figure 5 It is a transverse sectional view showing the structure of Embodiment 2 of the switchgear of this invention. Figure 6 will be Figure 5 An enlarged cross-sectional view of the main part of the switchgear near the breaker is enlarged and cut away. Figure 5 and Figure 6 Among them, in the switchgear 100A of the present embodiment, the circuit breaker 10A has the structure of the circuit breaker 10 of the first embodiment, and the resistance contact part 3 is added thereto. The resistance contact part 3 is connected in parallel with the main contact part 1 . In addition, the resistance contact part 3 is connected in series with the resistor 9 .

[0051] Figure 6 Among them, the circuit breaker 10A is equipped with: a main contact part 1 composed of a movable main contact 1a and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com