Thermal development apparatus

A thermal development, photothermal technology, used in instruments, equipment for electrical recording processes using charge patterns, optics, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

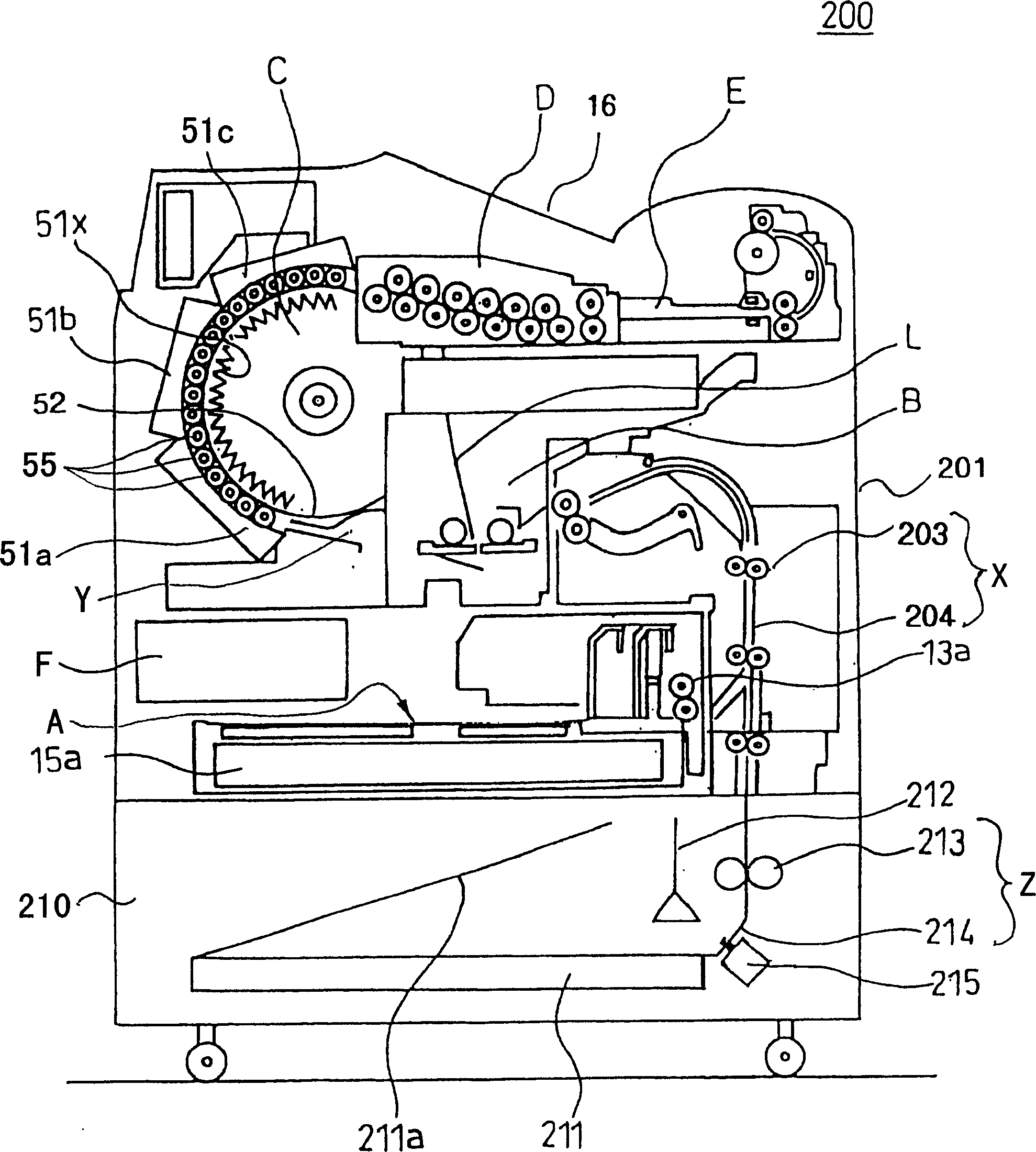

[0076] The thermal development recording apparatus according to the first embodiment of the present invention is capable of double-sided heating. thermal imaging device in figure 1 displayed in . exist figure 1 In , reference numeral 200 denotes a thermal development recording apparatus (image processing apparatus) of the first embodiment of the present invention. The thermal developing recording device 200 includes: (1) a thermal developing device 201 for exposing / developing an image obtained from CT or MRI; A double-sided photosensitive film cassette storage section 210 for a double-sided photosensitive film photographed by an X-ray device.

[0077] The thermal developing device 201 and the double-sided photosensitive film cartridge storage portion 210 are explained below. The thermal developing device 201 picks up slices of the photothermographic image material one sheet at a time from the supply tray 15a in the photothermographic image recording material feeding sect...

no. 2 approach

[0098] The thermal developing device according to the second embodiment of the present invention is capable of loading a raw film.

[0099] Typically, sheets of double-sided photosensitive film are loaded into double-sided film cassettes, and this loading is performed by an X-ray technician or by using a film loader (automatic film loading machine). Therefore, the loading work for loading the double-sided photosensitive film into the double-sided photosensitive film cassette is troublesome. In addition, film loaders are expensive and require installation space.

[0100] figure 1 The thermal developing device shown has a supply tray 15a containing a photothermographic material, and a film stock for laser recording is loaded therein. As described above, the raw film is usually conveyed from the supply tray to the laser recording section B by the first conveying section X (the conveying roller pair 203 and the conveying guide 204 ). In the laser recording section B, a latent ...

no. 3 approach

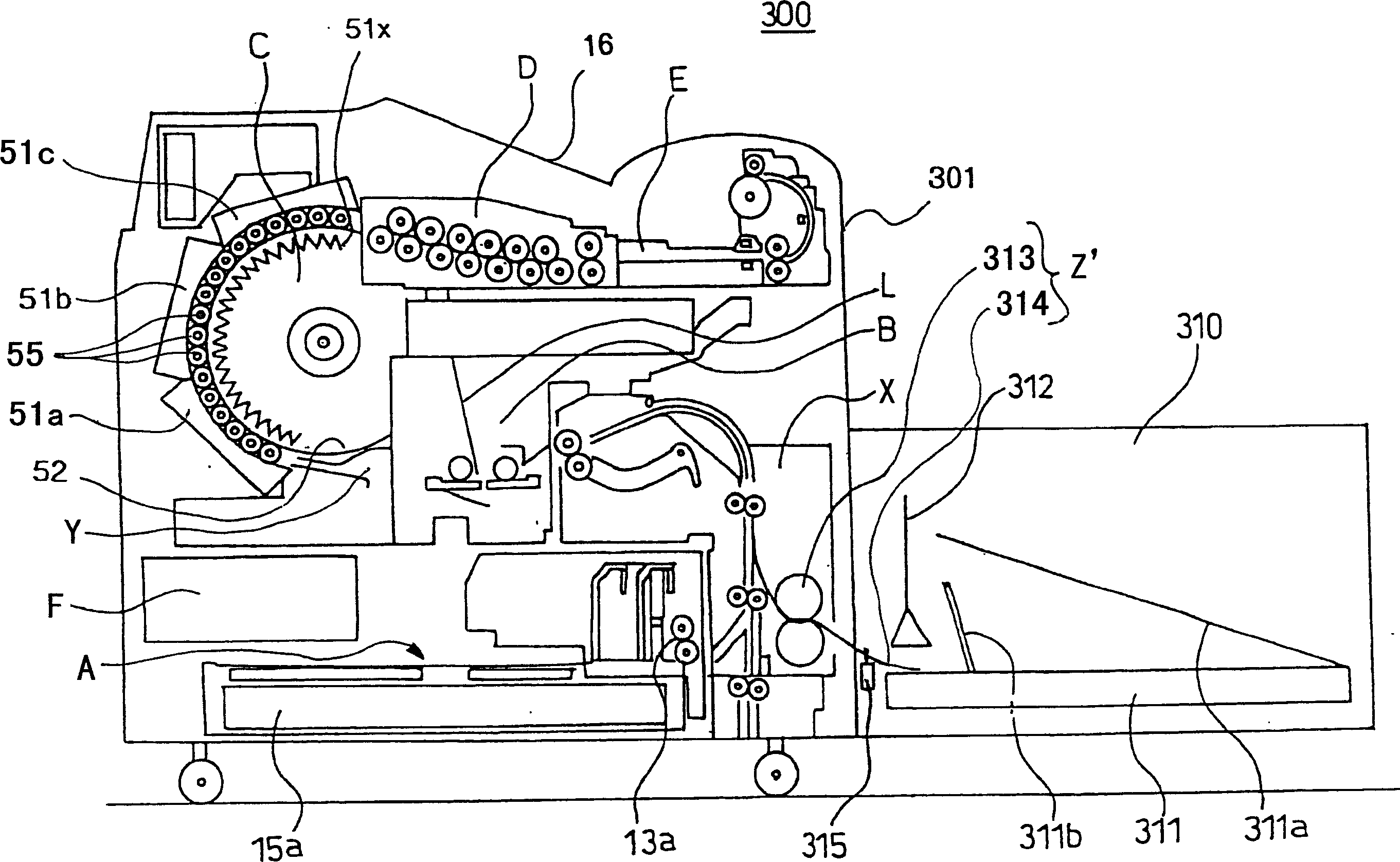

[0106] The thermal developing apparatus according to the third embodiment of the present invention may be provided with a position for loading a double-sided photosensitive film cassette. The thermal developing device is shown in image 3 .

[0107] figure 1 A thermal developing device having a cartridge storage portion at its lower portion is given, but the cartridge storage portion may be provided at its side. image 3 An example is given in which a cassette storage portion is provided on the side of the device.

[0108] exist image 3 In , 300 denotes a thermal developing device (image processing device) relating to the third embodiment of the present invention. The thermal developing device 300 includes: (1) a thermal developing unit 301 for exposing / developing images obtained from CT or MRI; and (2) a double-sided photosensitive film container 310 on a side of the thermal developing unit 301 for The double-sided photosensitive film photographed by the X-ray device i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com