Fabrication technology of strap wheel with locking and adjusting nut

A technology for adjusting nuts and manufacturing processes, which is applied to the parts of strapping machines and strapping materials, etc., can solve problems such as unsatisfactory tension adjustment effects, achieve unsatisfactory tension adjustment effects, reasonable technology, and ingenious ideas Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

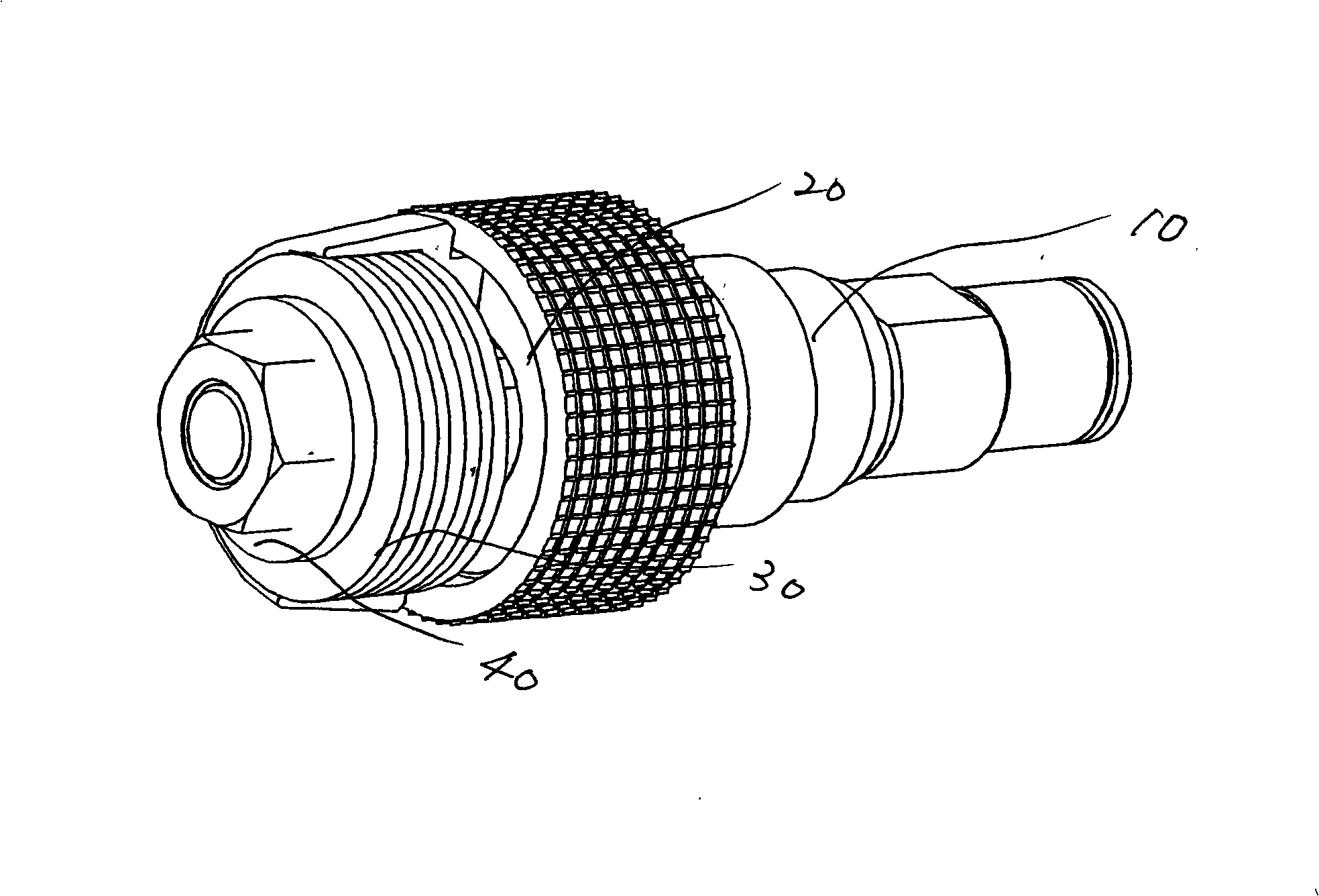

[0008] A manufacturing process of a pulley with locking and adjusting nuts mainly includes the following steps: locking and adjusting nuts are provided outside the folded springs provided in the body. Below in conjunction with accompanying drawing, the structure of the pulling pulley with locking, adjustment nut that the invention manufactures is described in further detail. A pulling pulley with locking and adjusting nuts is mainly composed of a body 10 in which a friction clutch 20 is provided with a folded spring 30 outside the folded spring and a lock nut 40 outside the folded spring.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap