Method and parts for assembling and molding ball and rods

A technology of parts and spheres, applied in the field of parts assembly, which can solve the problems of inability to move, lack of three-dimensional sense, and single combination.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

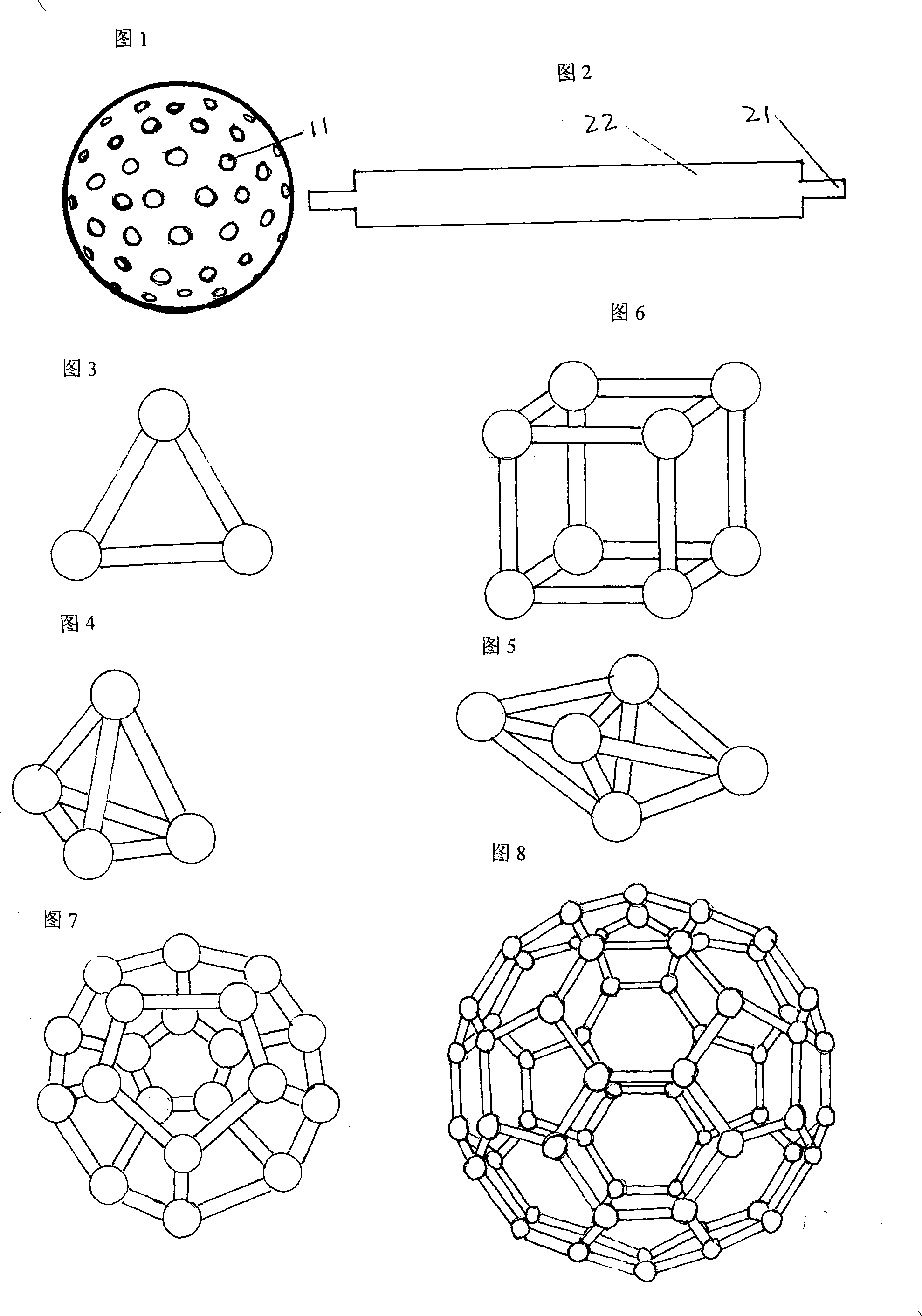

[0031] Modeling example 1: a plane triangular shape assembled with 3 spheres and 3 rods (see Figure 3);

[0032] Modeling example 2: a three-dimensional triangle model assembled with 4 spheres and 6 rods (see Figure 4);

[0033] Modeling example 3: a three-dimensional rhombus shape assembled with 5 spheres and 9 rods (see Figure 5);

[0034] Modeling example 4: a cube model assembled with 8 spheres and 12 rods (see Figure 6);

[0035] Modeling example 5: a perfect circular three-dimensional model 1 assembled with 20 spheres and 30 rods (see Figure 7);

example 6

[0036] Modeling example 6: a perfect circular three-dimensional model 2 assembled from 60 spheres and 90 rods (see Figure 8).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com