Heavy duty movable-point frog

A core rail and frog technology, which is applied in the field of heavy-duty movable core rail frogs, can solve the problems of poor bending resistance of the core rail section, large traffic interference, and insufficient service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

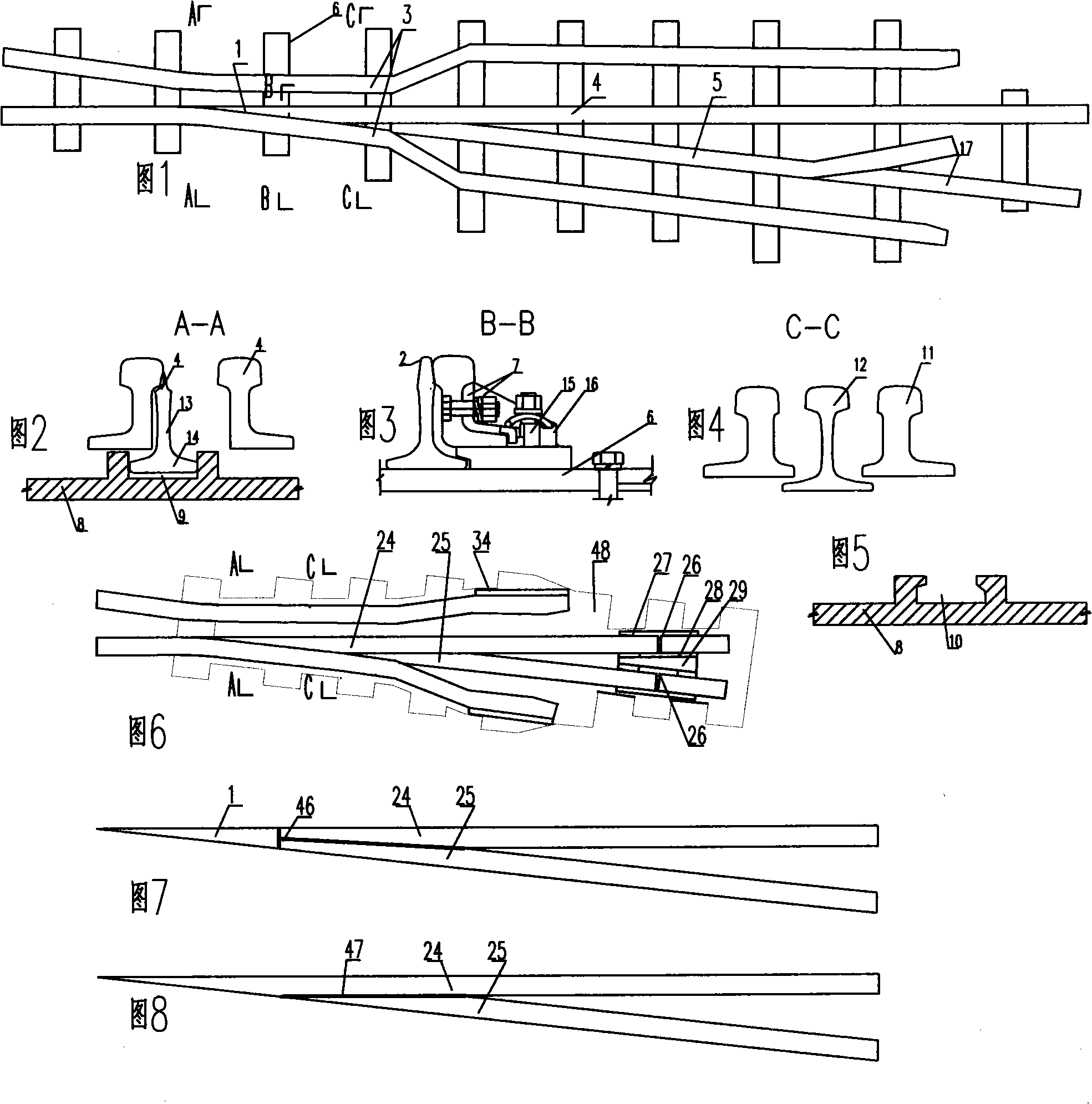

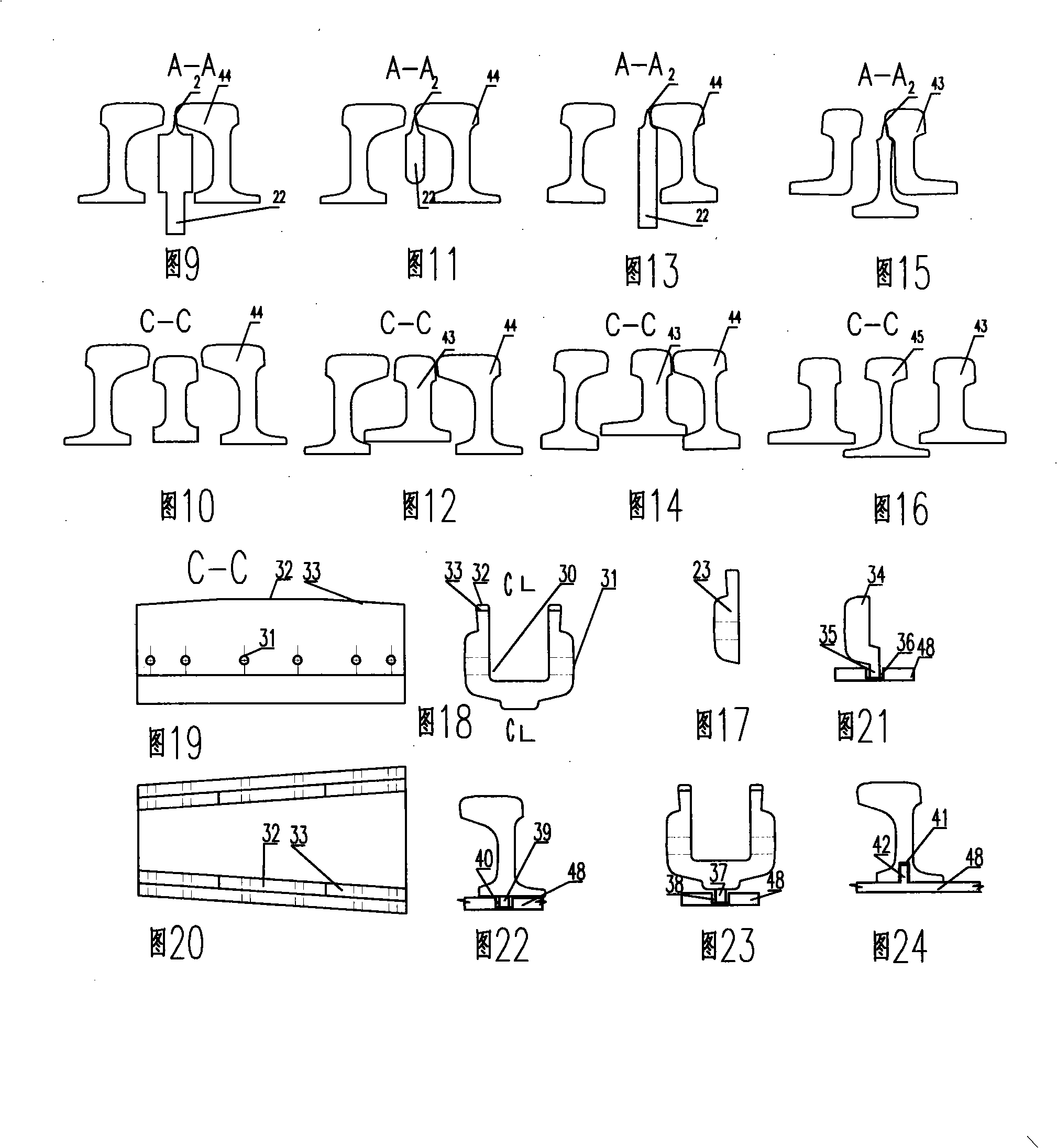

[0019] One of the embodiments of the present invention is shown in Fig. 1, Fig. 2, Fig. 3, and Fig. 4. Its structural technical characteristics are: the plane of the tip portion 1 of the heart rail is triangular so that the straight side strands of the heart rail can be driven; The upper part of the side is respectively processed into a convex curve 2 that matches the wheel tread and the shape of the rim, so that the wheel can pass through the center rail smoothly; there is a backing plate 6 under the center rail to support the center rail, and the center rail can slide on the backing plate; the wing rail The relative position of the wing rail can be maintained by connecting at least one limit rail support 7 with the backing plate 6 through fasteners: the hook lock 8 of the core rail has a groove-shaped cross-sectional structure 9 or a hook-groove type matching with the core rail bottom 14 The section structure 10 can pull the core rail through the movement of the hook lock; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com