Ready-made garment jimping wearing test method and device thereof

A wear test and test device technology, applied in the direction of testing wear resistance, etc., can solve problems such as difficult to detect durability performance indicators, and achieve the effect of simple and easy testing and grade evaluation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and specific examples.

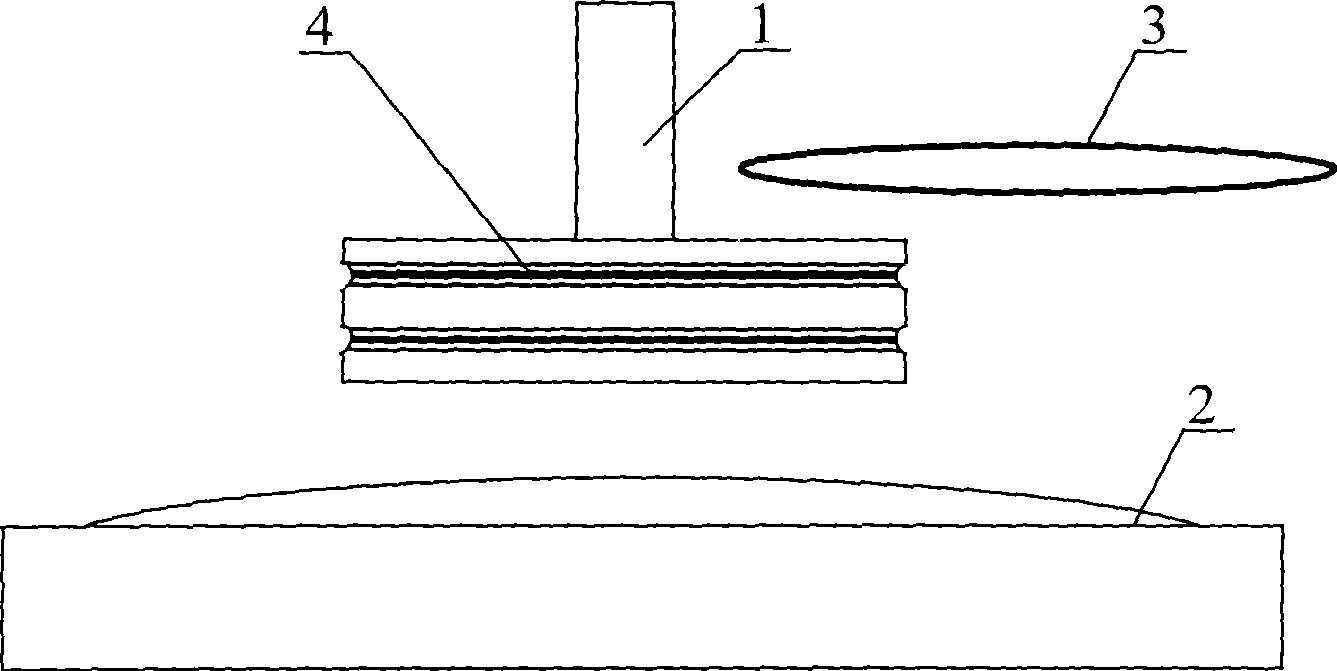

[0017] The basic structure of the test device used is as follows figure 1 As shown, it includes an abrasive loader 2 and a sample loader 1 with a disc installed above the abrasive loader 2 . Abrasives are fixed on the upper surface of the abrasive loader 2 . Two ring-shaped grooves 4 are formed in the circumferential direction of the disk of the sample loader 1 . The upper end of the sample to be tested is compressed and fixed in the annular groove 4 through the elastic ring 3 .

[0018] The abrasive can be a fabric abrasive: the same as the fabric of the mouth end or edge parts such as clothing cuffs. Other soft abrasives are also possible.

[0019] The abrasive can be lined with a foam pad. The foam padding weighs about 270g / m 2 , about 8 mm in thickness, and the diameter of the sample gasket conforms to the size of the abrasive loader.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com