Terminal crimping method, terminal crimping device, and terminal-crimped electric wire manufacturing apparatus

A terminal crimping and wire technology, which is applied in the direction of connection, circuit, connection and other directions by deformation, which can solve the problems of increasing time-consuming and labor-intensive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

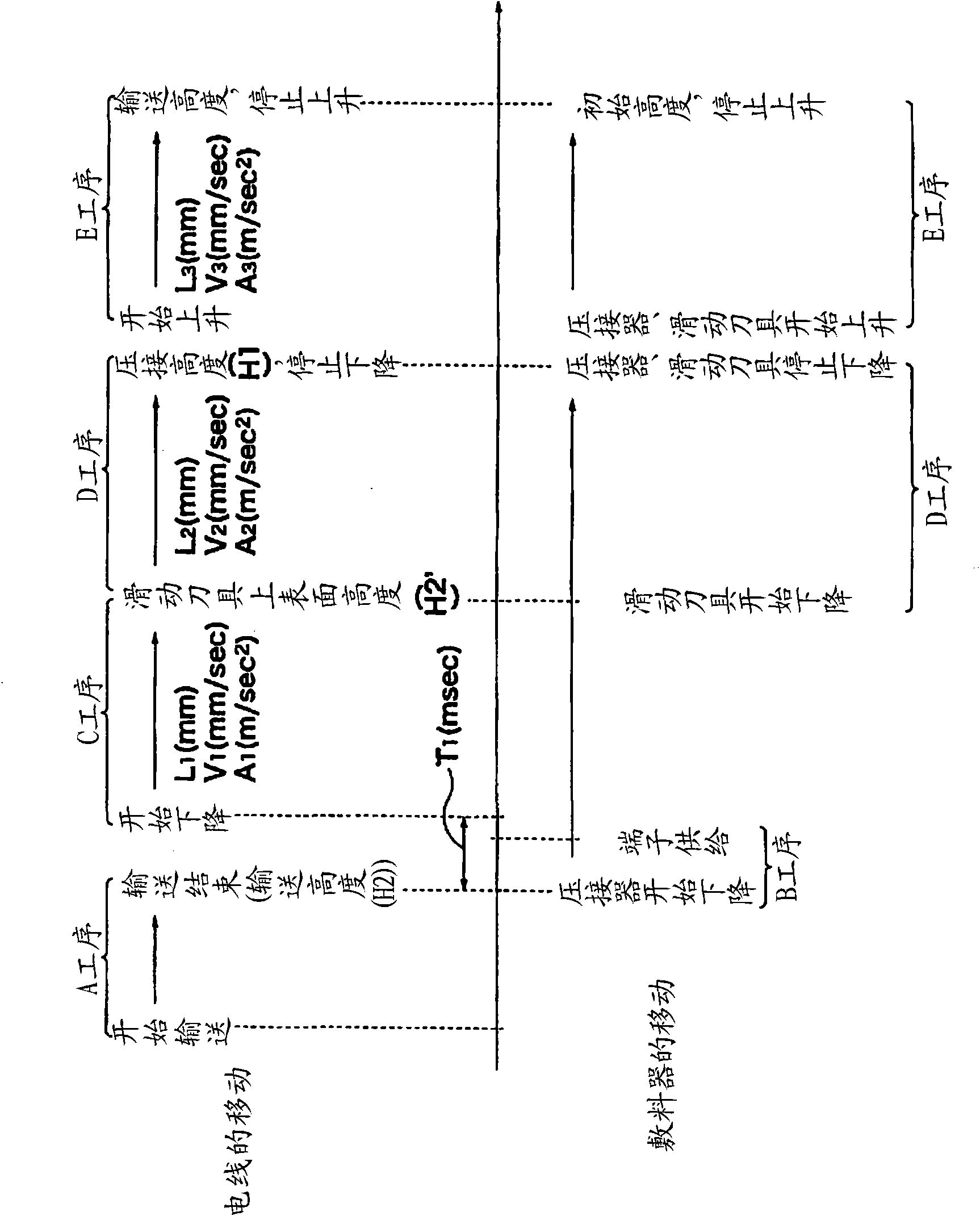

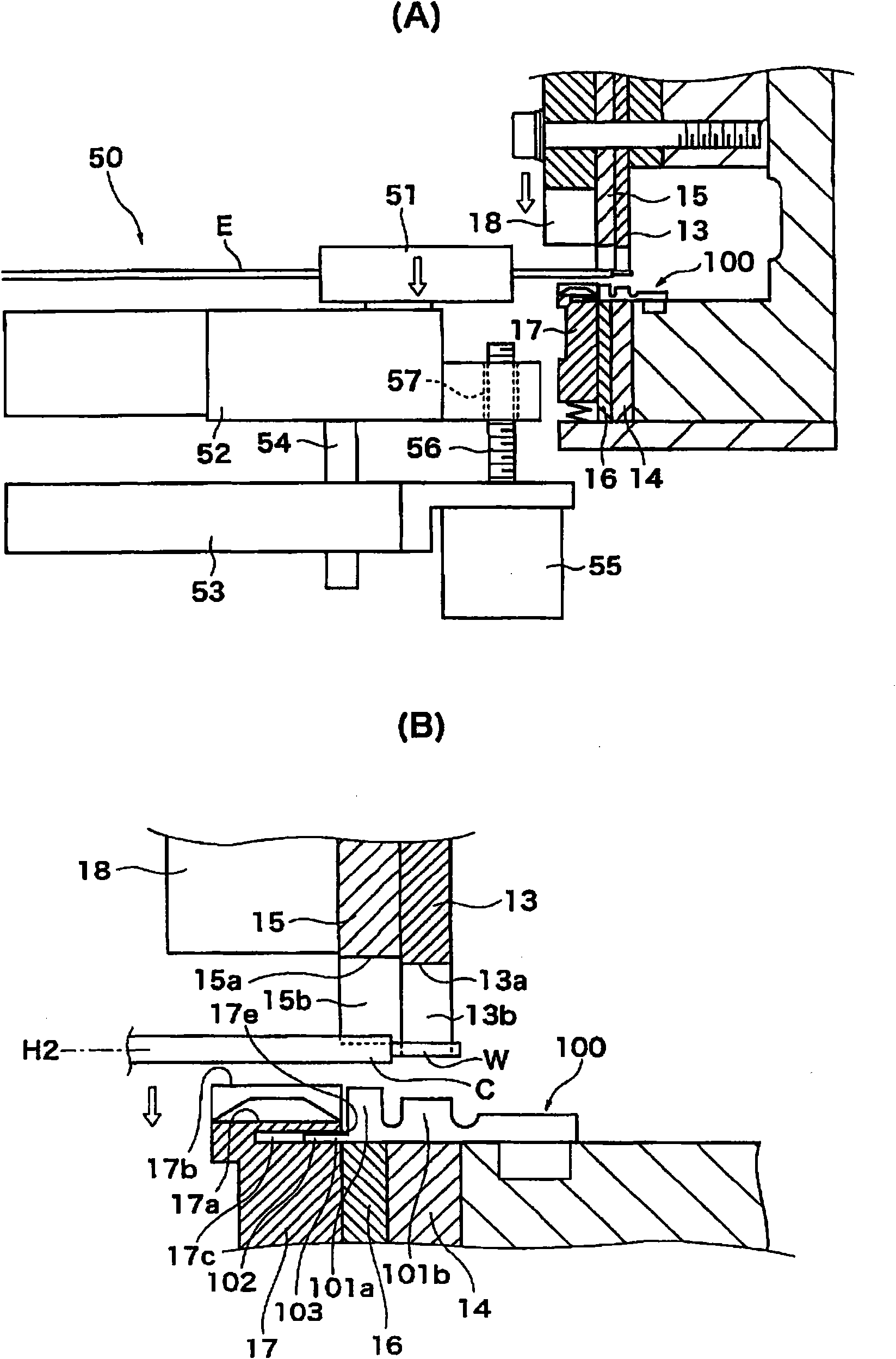

[0104] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings.

[0105] First, a terminal crimping electric wire manufacturing apparatus will be described.

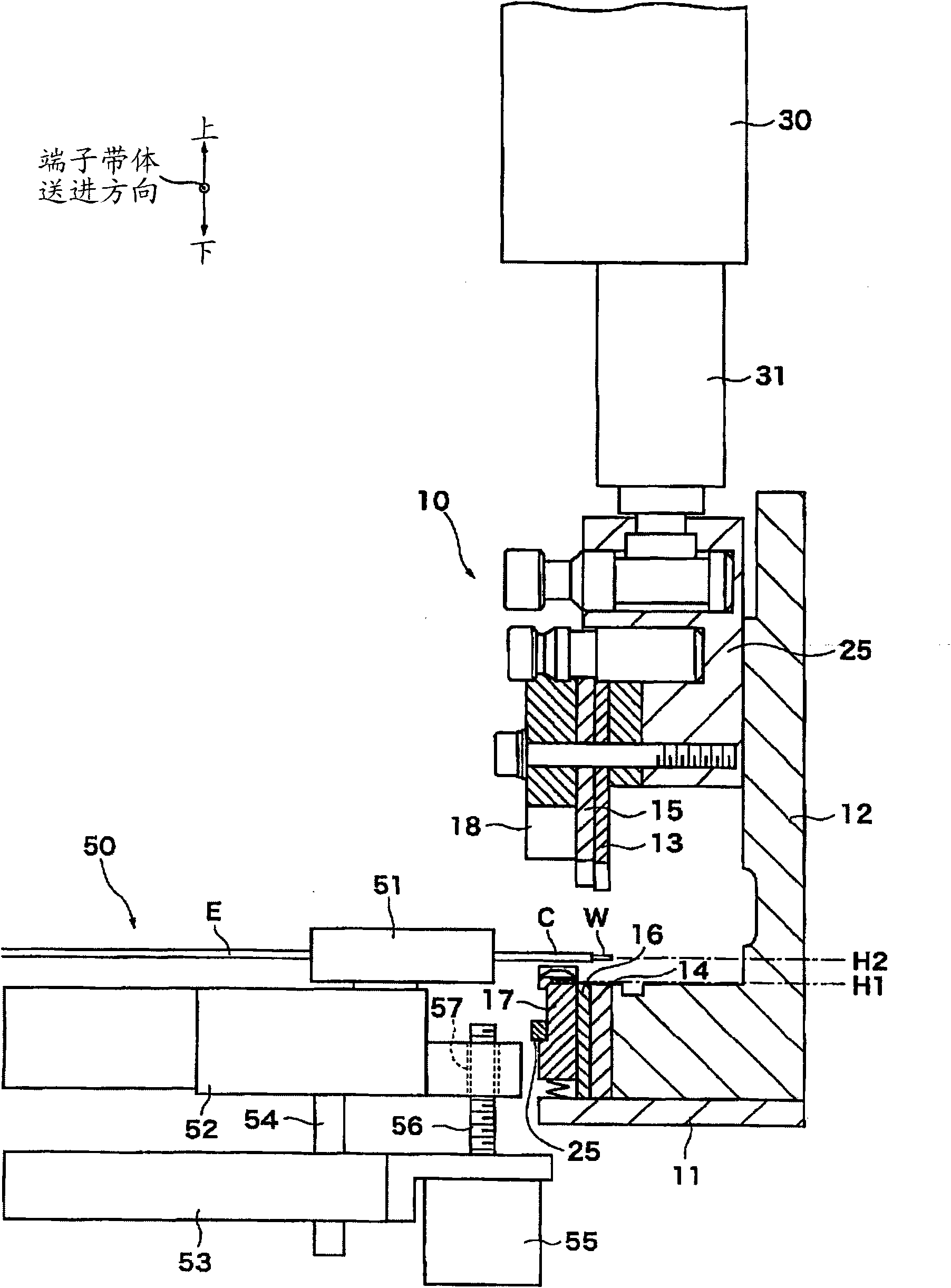

[0106] Figure 8 It is a figure for explaining an example of the structure of a terminal crimping electric wire manufacturing apparatus.

[0107] In this example, a device for cutting an electric wire to a predetermined length, peeling off the sheath at both ends of the cut electric wire, and crimping a terminal to the exposed electric wire at both ends will be described.

[0108] The terminal crimping electric wire manufacturing apparatus 1 mainly includes the electric wire feeding device 2 that feeds out a predetermined length of electric wire at a time from the electric wire wound in a drum shape, two clamp devices 50A and 50B that hold and feed the electric wire, the electric wire cutting device 3, and the base side The stripping device 4A of the front end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com