Two-way overload protective device for drive mechanism

A technology of overload protector and driving mechanism, which is applied in the direction of automatic disconnection emergency protection device, emergency protection circuit device, and measuring the force applied to the control element, which can solve the problems of inability to play a protective role

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

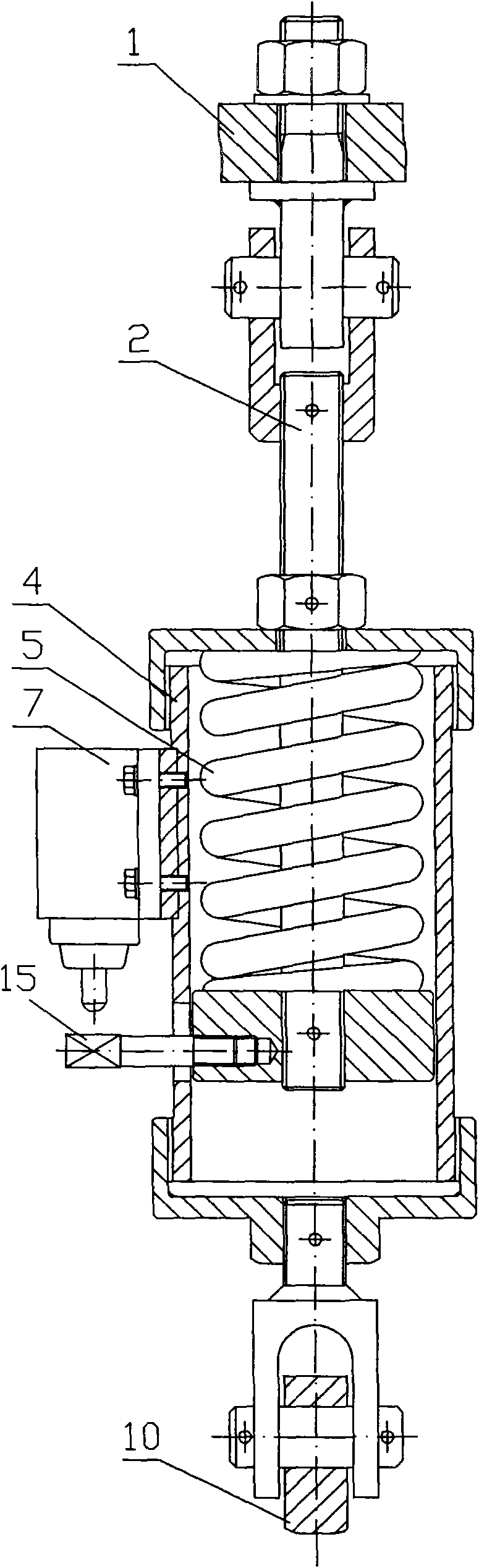

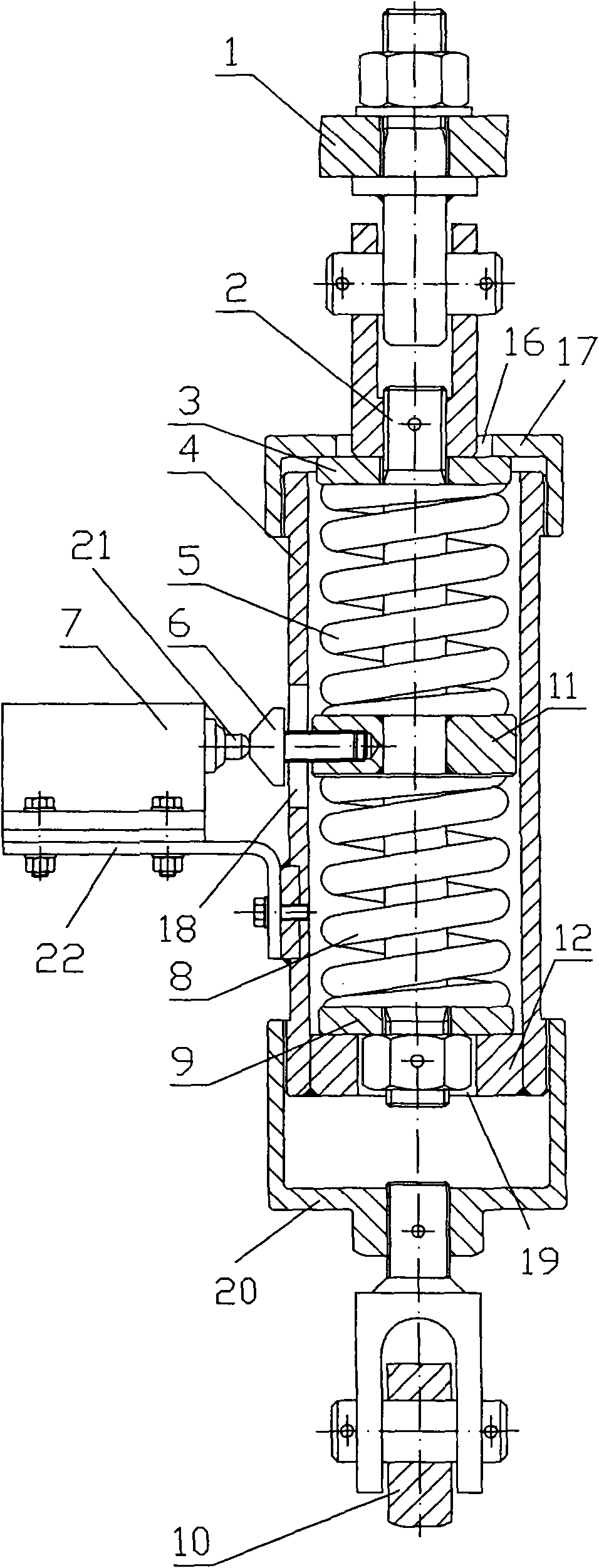

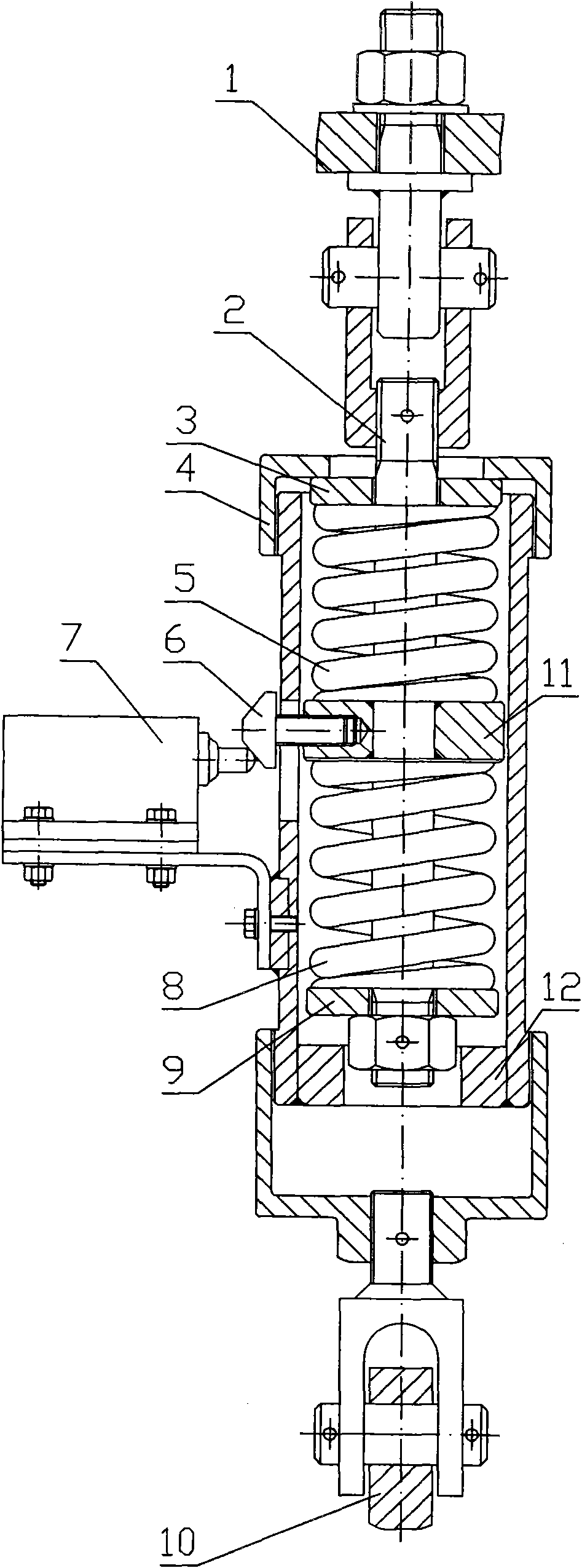

[0013] As shown in the figure: the two-way overload protector used for the driving mechanism includes an outer cylinder 4 and a pull rod 2 that can move up and down in the outer cylinder 4. There is a spring set outside the pull rod 2 in the outer cylinder 4. The feature is that the spring has a first spring 5 at the top and a second spring 8 at the bottom, and the first pressing plate 11 is fixedly connected to the pull rod 2 between the first spring 5 and the second spring 8; A thrust rod 6 is set on the first pressure plate 11; a push rod hole 18 is set on the side wall of the outer cylinder 4 corresponding to the position of the thrust rod 6, and the outer end of the thrust rod 6 protrudes from the push rod hole 18, And the working surface is formed at the end of the extended end of the thrust rod 6; a travel switch 7 is set outside the outer cylinder 4 corresponding to the position of the thrust rod 6, and the contact 21 of the travel switch 7 is connected to the Cooperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com