Method for identifying tire profile of deviation angle of axel arranging and device thereof

An identification method and skew angle technology, which are used in measuring devices, using optical devices, and testing the alignment of automobile headlights, etc., can solve problems such as inaccurate measurement results, and achieve high detection accuracy, convenient operation, and small space. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific content of the present invention and its specific implementation will be further described below in conjunction with the embodiments shown in the accompanying drawings.

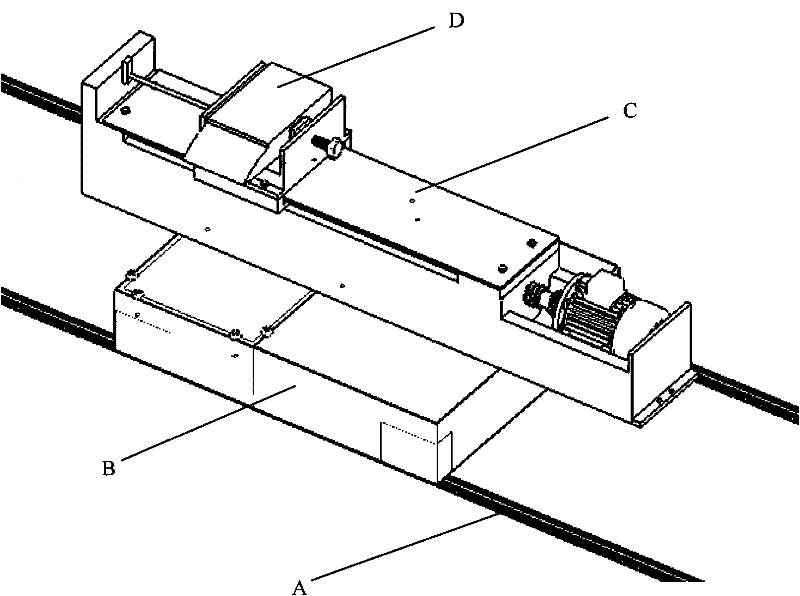

[0023] refer to figure 1 , the tire profile identification device for placing the deflection angle of the axle of the invention is mainly composed of double guide rails A, base assembly B, travel device C hardware device equipment.

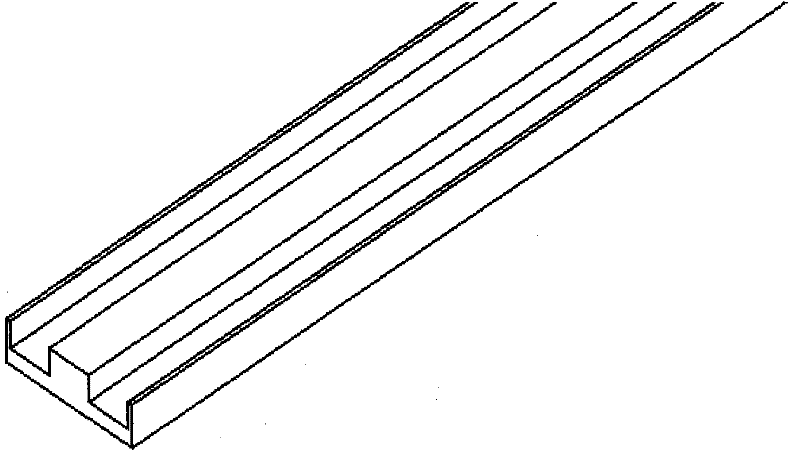

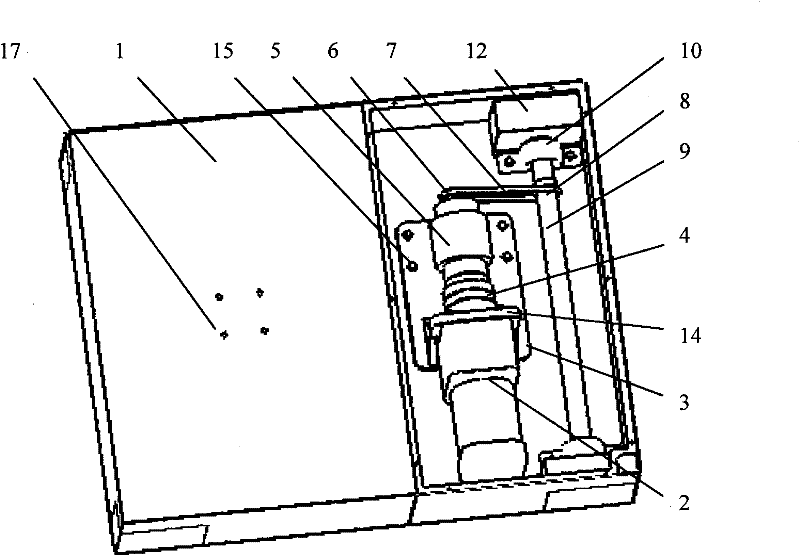

[0024] refer to figure 2 , the double guide rail A is the motion track of the base assembly B, and the movement of the base assembly B is realized by four base wheels 11 on its bottom surface. When the base assembly B moves on the double guide rail A, the laser range finder D collects data at all times, and automatically finds and locks the position of the rear wheel of the vehicle under inspection according to the obtained data curve. When returning to the position of the rear wheel again, the stepper motor 2 in the base assembly B stops automatically, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com