Manufacturing method of air-filled tubeless tire for flat tire rim

A technology for a pneumatic tire and a manufacturing method, which is applied to tires, applications, household appliances, etc., can solve the problems of production, promotion and use obstacles, and troublesome manufacturing processes, and achieves the effects of low manufacturing cost, simple method, and practical process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

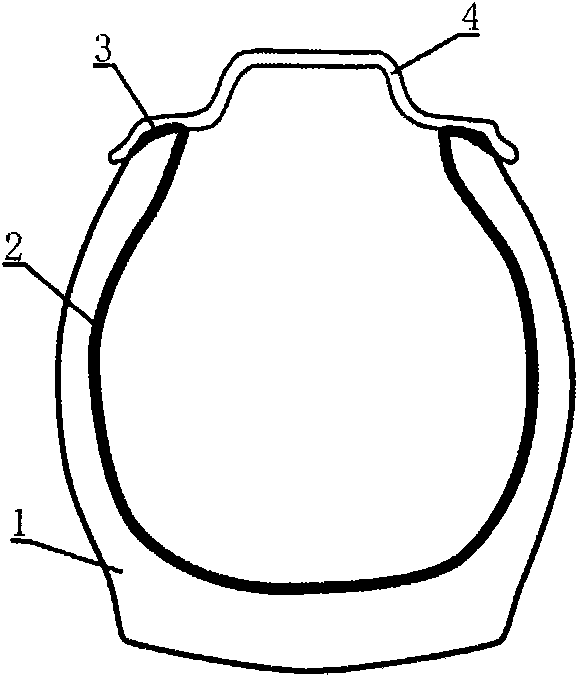

[0028] figure 1 Marking description: tire 1, inner liner 2, sealing layer 3, rim 4.

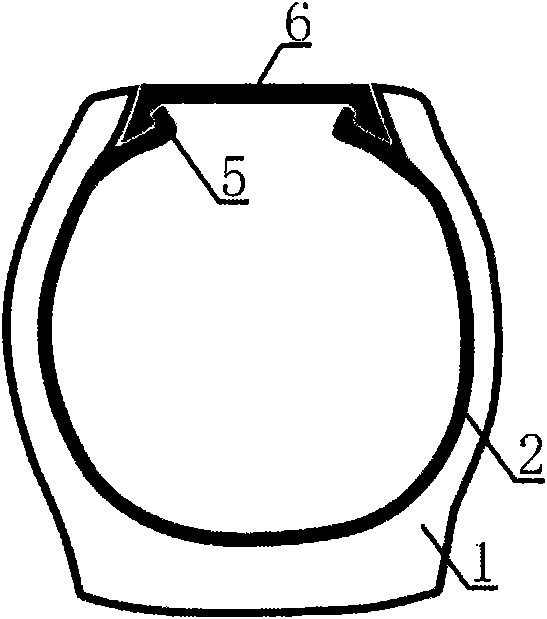

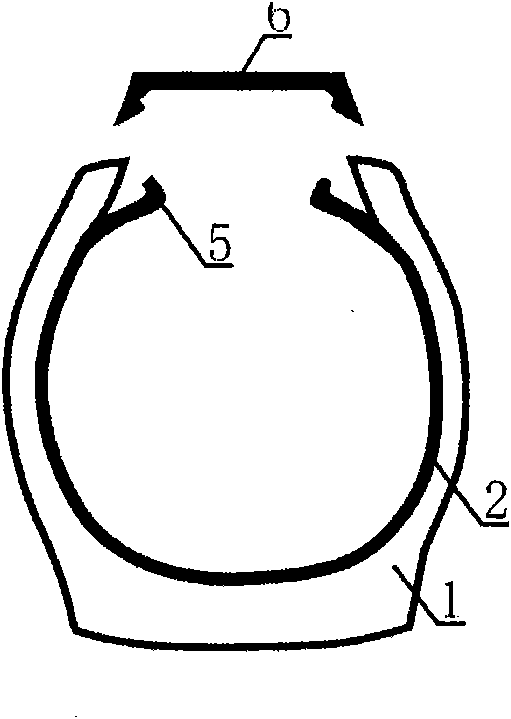

[0029] figure 2 Description of markings: pocket support 5, bag lid sealing buckle 6.

[0030] Figure 4 Marking Description: Mold 7.

[0031] Figure 8 Labeling Description: Capsule 8.

[0032] The embodiment of the manufacturing method of the flat rim tubeless pneumatic tire of the present invention adopts the following steps to realize:

[0033] 1), see Figure 4 and Figure 7 , prepare the mold 7 of the pocket support 5, the mold 7 is divided into two symmetrical semicircles according to the circumferential direction, and is divided into three or more sections according to the radial direction;

[0034] 2), see Figure 5 According to the shape and size of the model, the pocket support 5 is manufactured, and the partial name of the pocket support 5 is divided into three parts: head, waist and root;

[0035] 3), see Image 6 , installing the head of the pocket support 5 in the mo...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap