Vacuum boosting device

A negative pressure, transformer chamber technology, applied in the direction of brake transmission, transportation and packaging, brakes, etc., can solve the problems of the axial length of the holding member and the complex structure of the cylindrical part, and achieve the effect of small and compact formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The best mode for carrying out the present invention will be described below using the drawings.

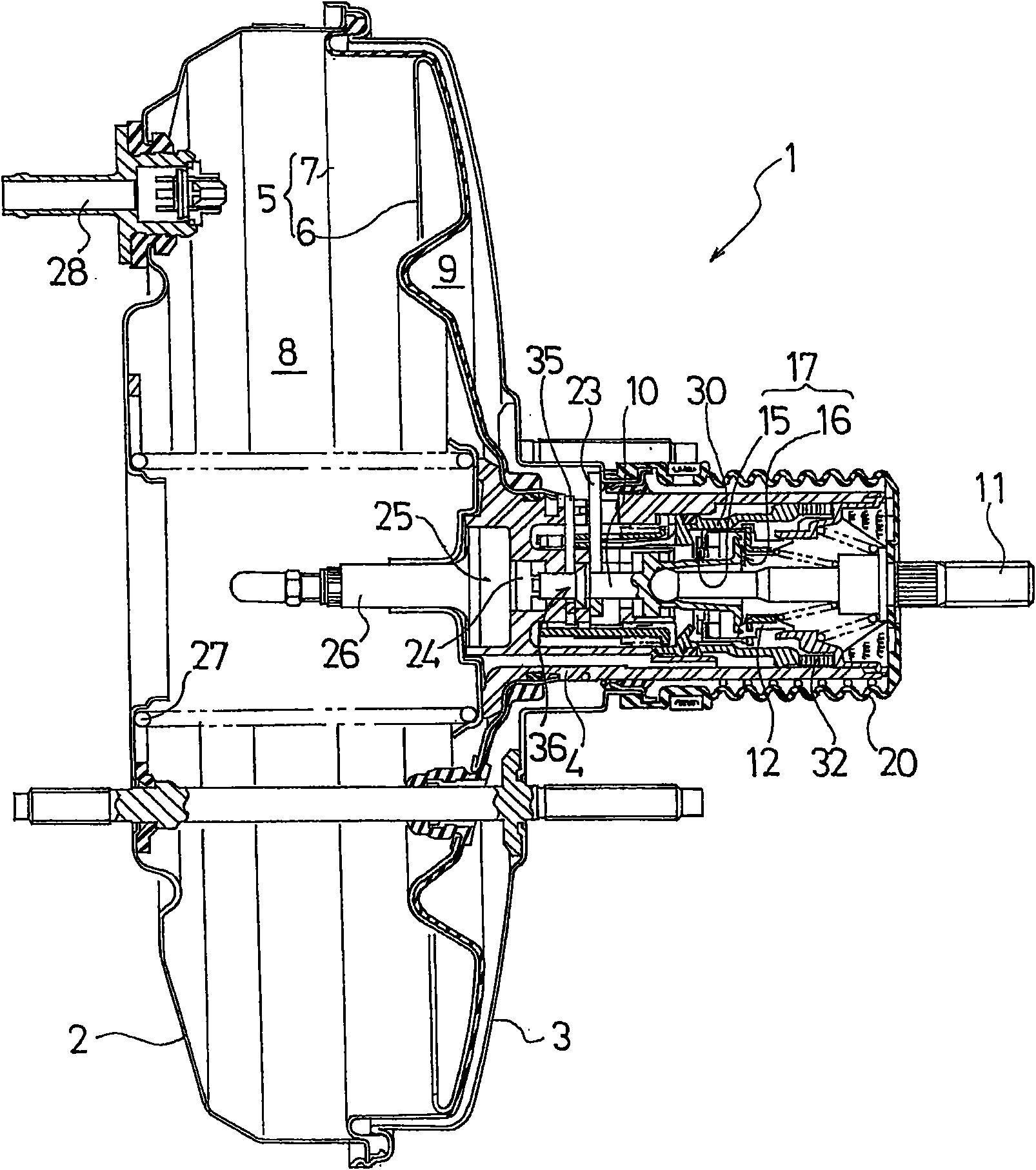

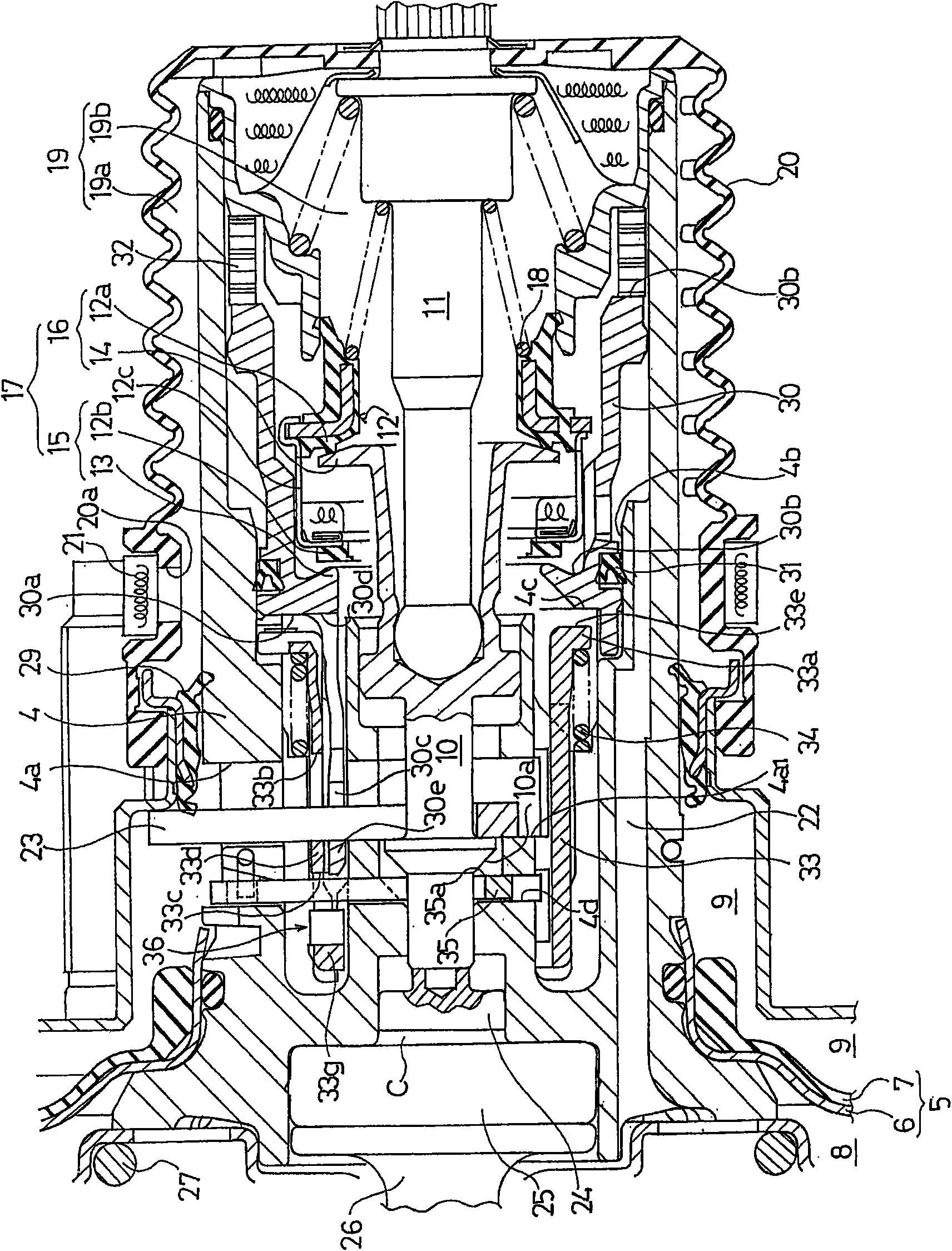

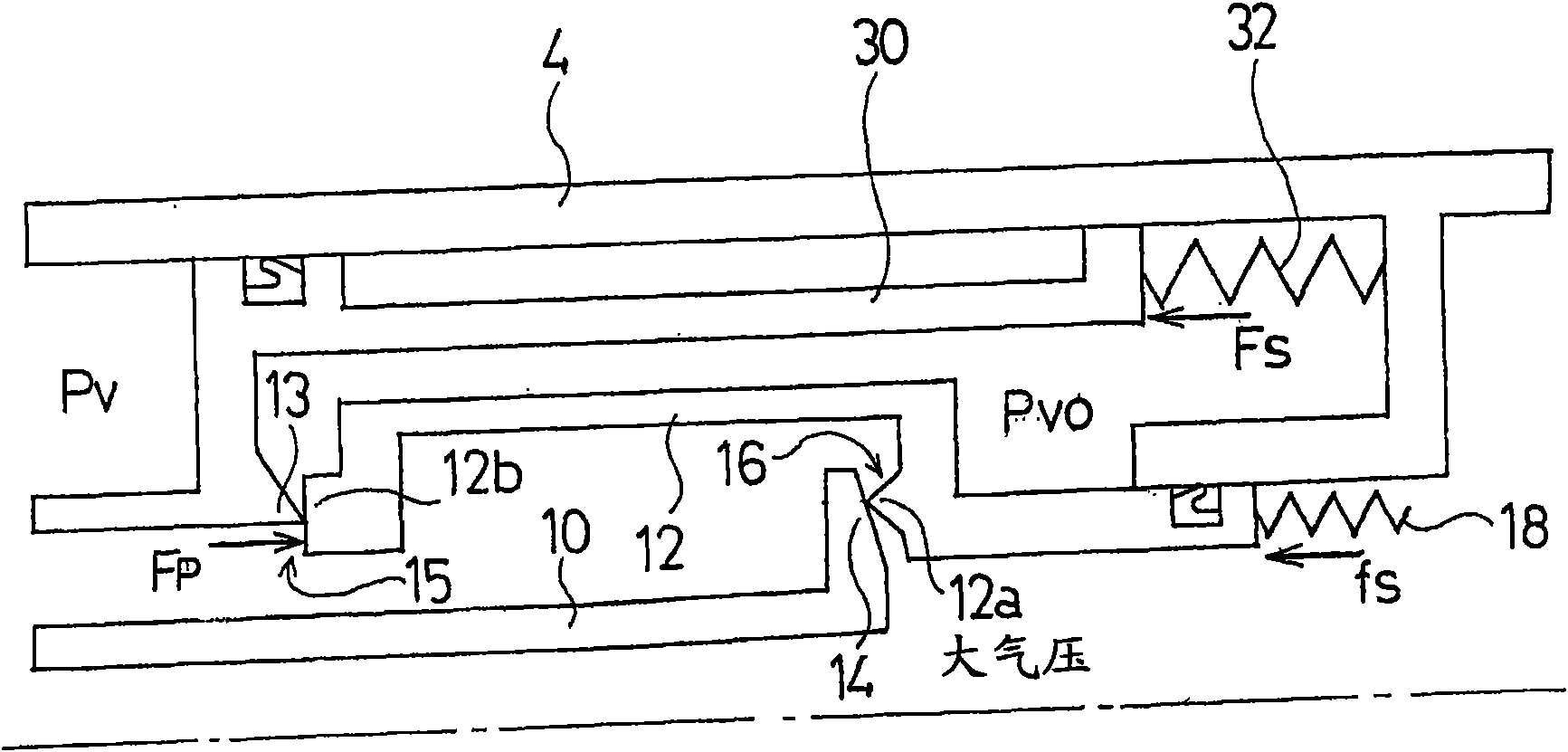

figure 1 It is a cross-sectional view showing an embodiment of the negative pressure multiplier of the present invention in a non-working state, and an example of a brake multiplier suitable for use in a braking system; figure 2 for enlarged display figure 1 Partially enlarged cross-sectional view of parts of medium vacuum valve and atmospheric valve. In addition, in the following description, "front" and "rear" represent "left" and "right" in each drawing, respectively.

[0019] First of all, with regard to the same constituent parts as the conventional negative pressure multiplier described in Patent Document 1 in this example negative pressure multiplier, and although it is different from the structure of the negative pressure multiplier described in Patent Document 1, it has nothing to do with the present invention. The components of the direct relationship will be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com