A Differential Positioning Seismograph While Drilling

A differential positioning and seismograph technology, applied in seismology for well logging records, etc., can solve problems such as inconvenient construction on site, unguaranteed trace spacing and offset, and trace spacing errors, etc., to ensure accuracy and guarantee Measurement accuracy and the effect of reducing seismic interpretation errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

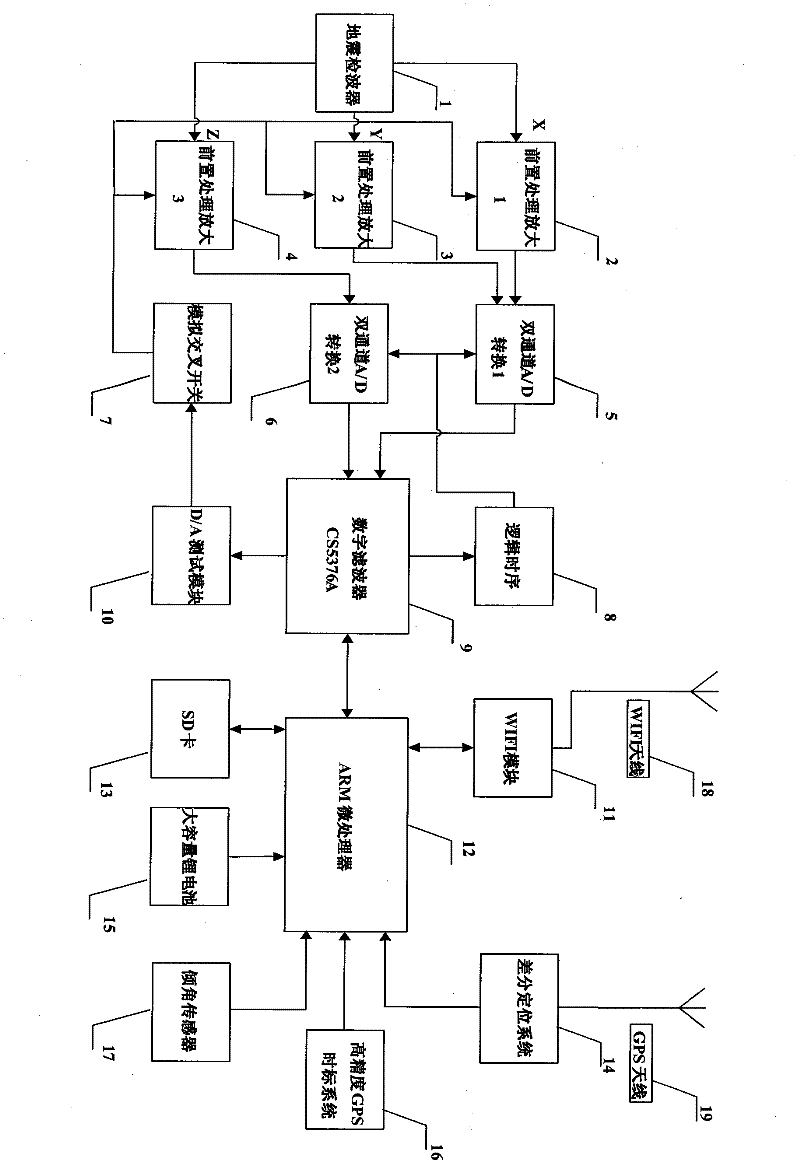

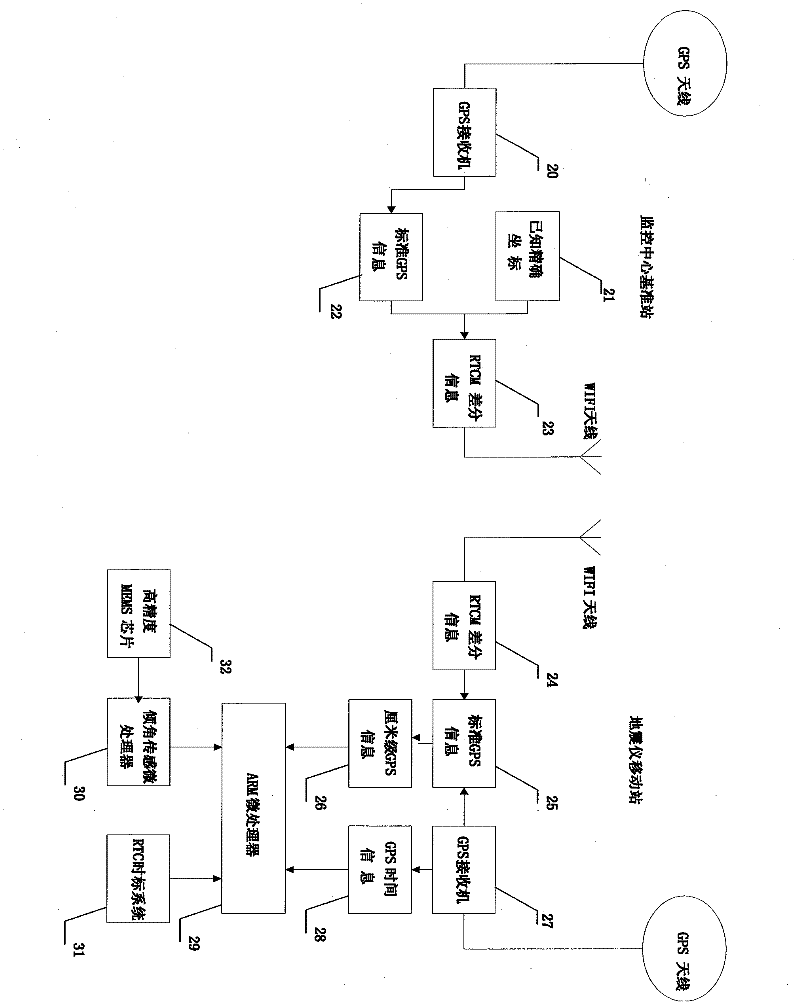

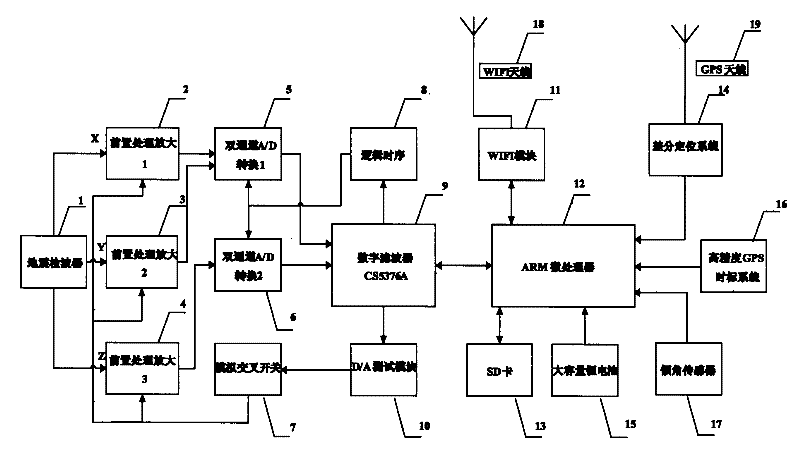

[0019] Now combined with the manual figure 1 And attached figure 2 , to further describe the present invention.

[0020] figure 1 It shows the circuit diagram of the differential positioning while drilling seismograph. The geophone (1) collects the vibration signal reflected in front of the drill bit, outputs X, Y, and Z three-channel analog components, respectively passes through the pre-processing amplification module, enters the dual-channel A / D conversion chip, and outputs digital signals to the digital filter CS5376A (9), after setting multi-stage filtering, be connected to ARM microprocessor (12) by SPI bus line and process. In order to ensure the stability of the seismic signal processing, the D / A test module (10) is controlled by the output of the digital filter CS5376A to replace the output of the geophone (1) with an analog signal of a known frequency range, so as to detect each component of the entire acquisition circuit. Item indicators and characteristics. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com