Intelligent scaffold fastener capable of monitoring dip angle changes

A technology of scaffolding and fasteners, which is applied in the field of scaffolding, can solve the problems of extended test period, increased workload of wired cables, easy to connect wrong wiring positions, etc., and achieves strong anti-electromagnetic interference ability, improved monitoring efficiency, and shortened monitoring cycle. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

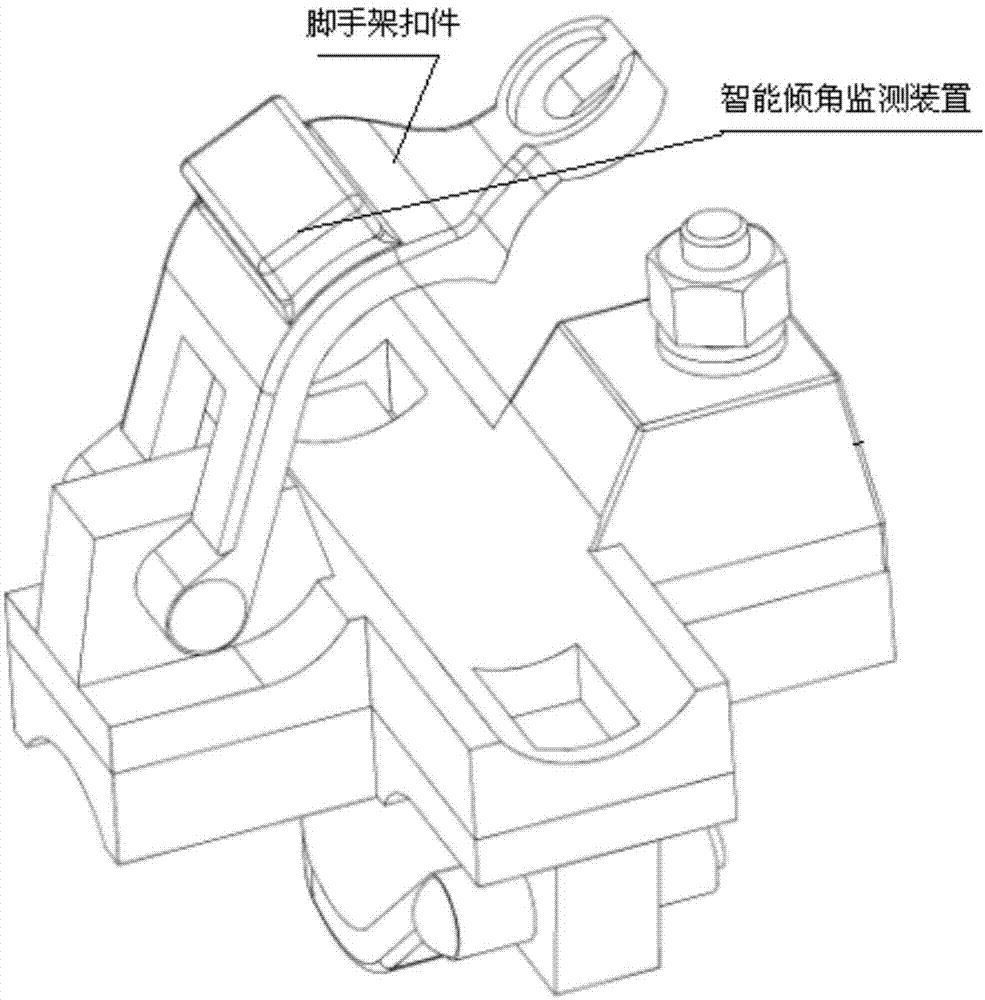

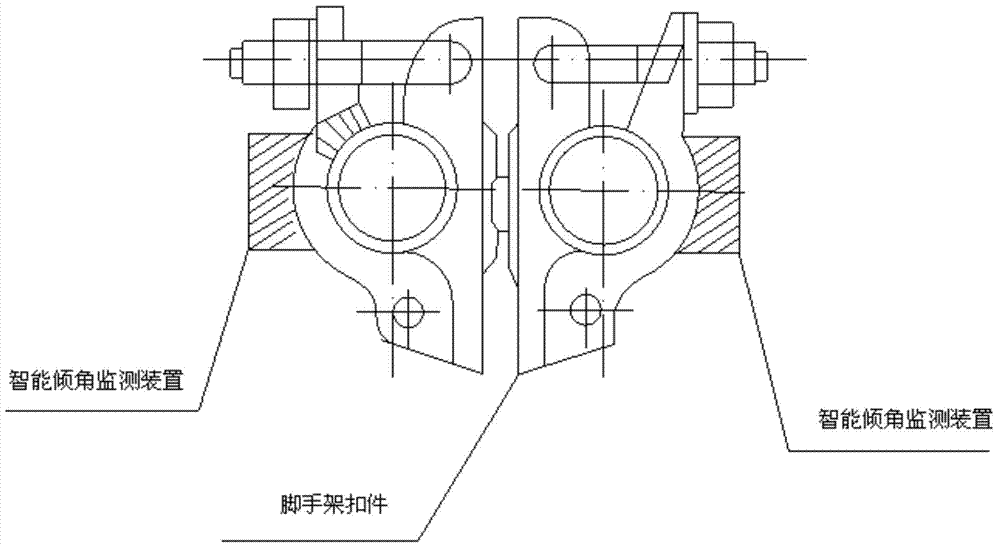

[0025] Such as figure 1 and figure 2 As shown, an intelligent scaffold fastener capable of measuring inclination angle changes according to the present invention includes a scaffold fastener and an intelligent inclination monitoring device pasted on the scaffold fastener.

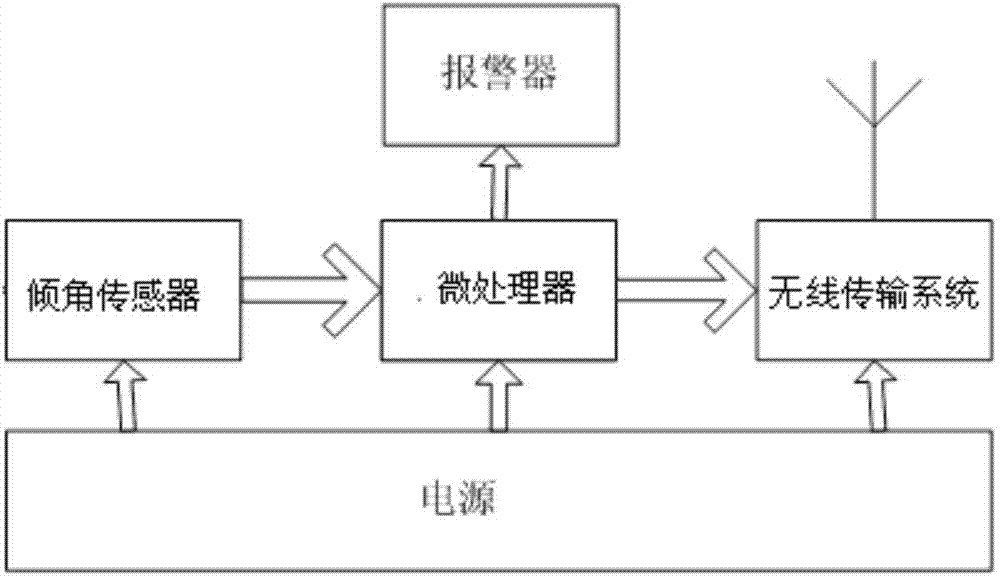

[0026] In the above example, if image 3 As shown, the intelligent inclination monitoring device includes the following components: an inclination sensor, a microprocessor, a power supply, a wireless transmission system, and an alarm, wherein the microprocessor is separately connected to the inclination sensor, the wireless transmission system, and the alarm. The power supply is connected with the inclination sensor, the microprocessor and the wireless transmission system respectively.

[0027] In the above embodiment, the inclination sensor is preferably a two-dimensional inclination sensor; preferably, the inclination sensor is a MEMS two-dimensional inclination sensor.

[0028] In the above embodimen...

Embodiment 2

[0035] Such as figure 1 and figure 2 As shown, a kind of intelligent scaffold fastener of the present invention that can measure stress changes, its basic structure setting and application are the same as that of Embodiment 1, and specifically includes the following settings: in the intelligent inclination monitoring device, through the biaxial acceleration sensor, The microprocessor and the wireless transmission system form the inclination sensor node and the network coordinator node; Wherein, the inclination sensor node receives the inclination data from the scaffold fastener, and transmits the inclination data to the A network coordinator node; the network coordinator node is used to complete the creation and management of the wireless network, and transmit the data of the inclination sensor nodes.

[0036] In the above example, if Figure 4 As shown, the biaxial acceleration sensor is preferably the ADXL213 biaxial acceleration sensor of ADI, the microprocessor is prefera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com