Keyboard and key lifting switching device thereof

A lift switch, keycap technology, applied in electrical switches, electrical components, circuits, etc., can solve the problems of cumbersome assembly process, not in line with high-efficiency production, etc., to improve the qualified rate of finished products, the keyboard feels good, and save production and assembly. The effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

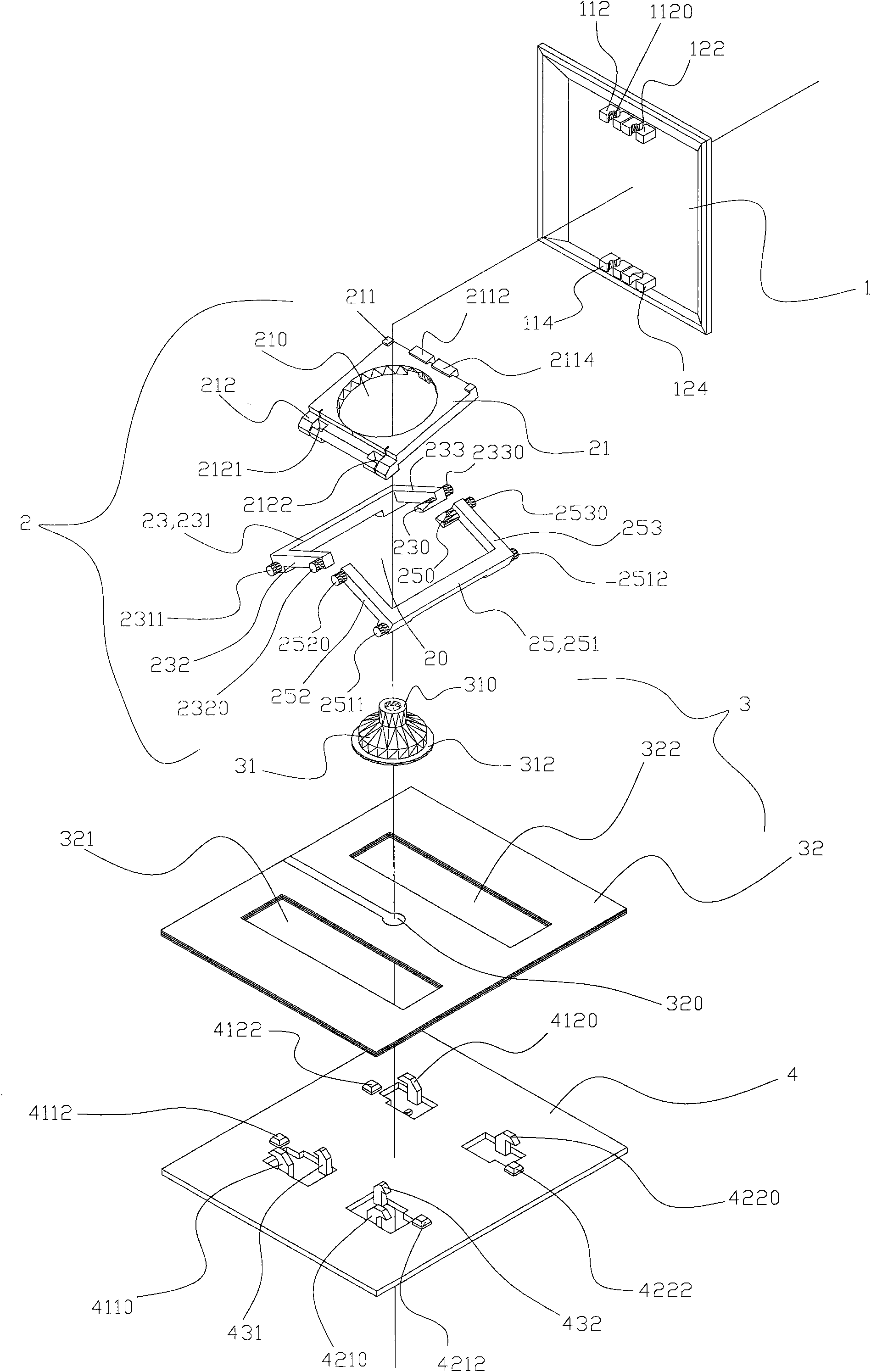

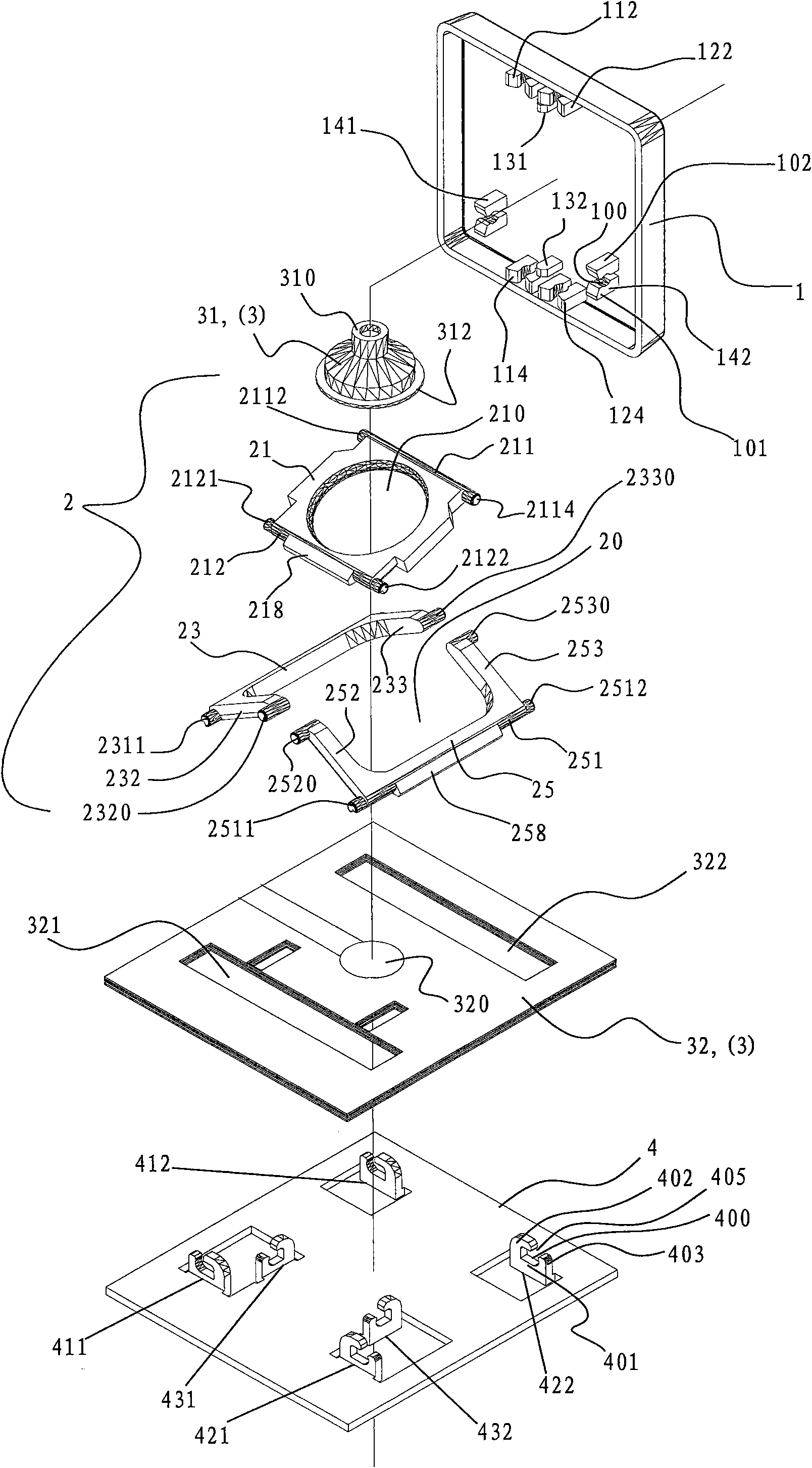

[0040] refer to figure 2 As shown, the key lifting switch device of the present invention is composed of a keycap 1, a telescopic assembly 2, a switch mechanism 3 and a support plate 4. The main improvement of the key lifting switch device of the present invention will be revealed as follows—the telescopic assembly 2 and some components on the bottom surface of the keycap 1 and the surface of the support plate 4 related to the improvement of the telescopic assembly 2 .

[0041] Please first understand the specific structure of the telescopic assembly 2 of the present invention:

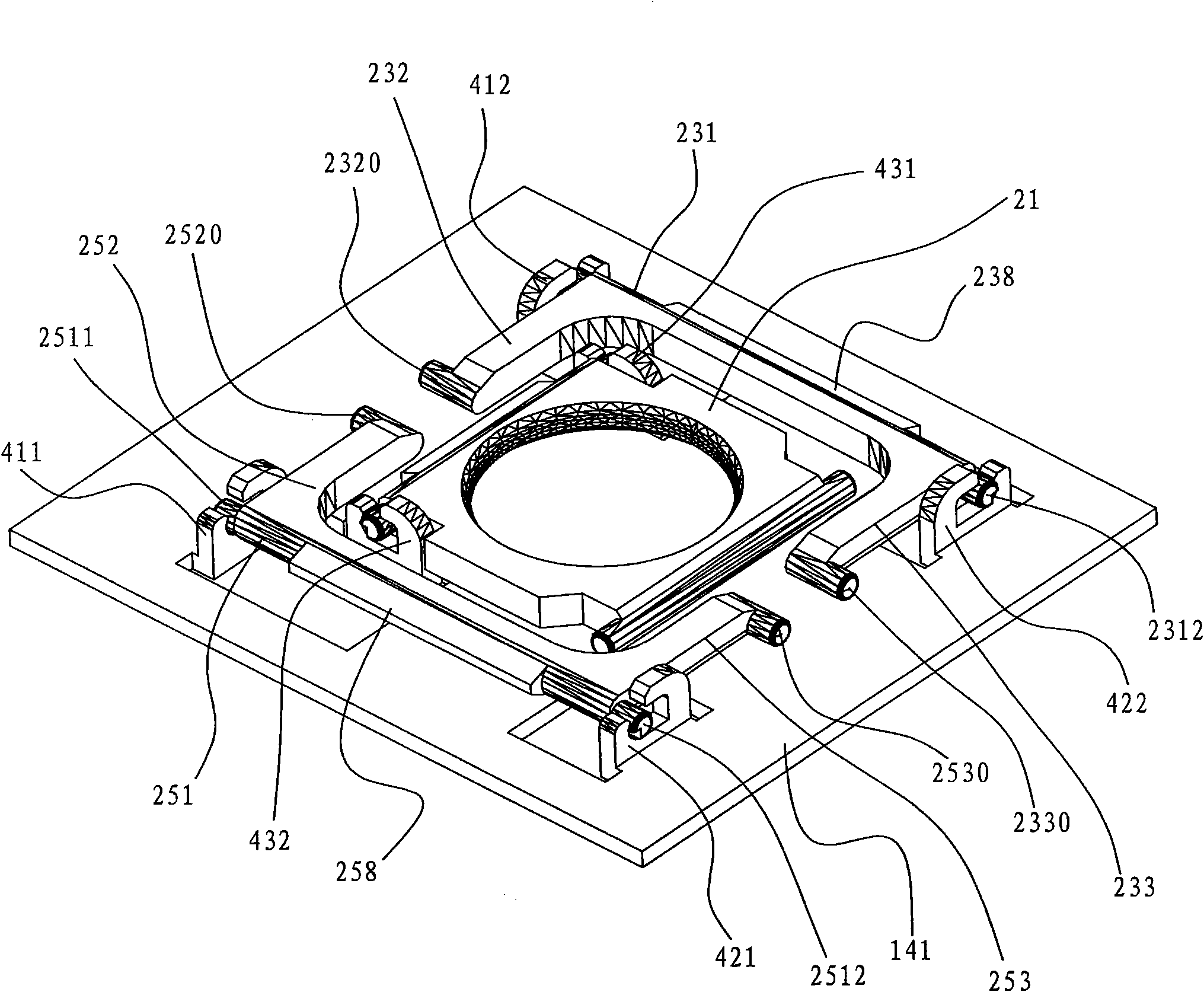

[0042] combine figure 2 with image 3 , the telescopic assembly 2 of the present invention includes a pair of U-shaped frames 23 and 25 with a symmetrical structure and a plate-shaped synchronous slide 21 .

[0043] The U-shaped frame 23, 25 includes figure 1 The first frame 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com