Keyboard, key direction switch device and respective assembling processes

A lift switch, keycap technology, applied in electrical switches, electrical components, circuits, etc., can solve the problems of narrowing the keys, the overall size of the keys is too large, the size of the keys is large, etc., to achieve smooth motion effect, narrow space area, The effect of overall size reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

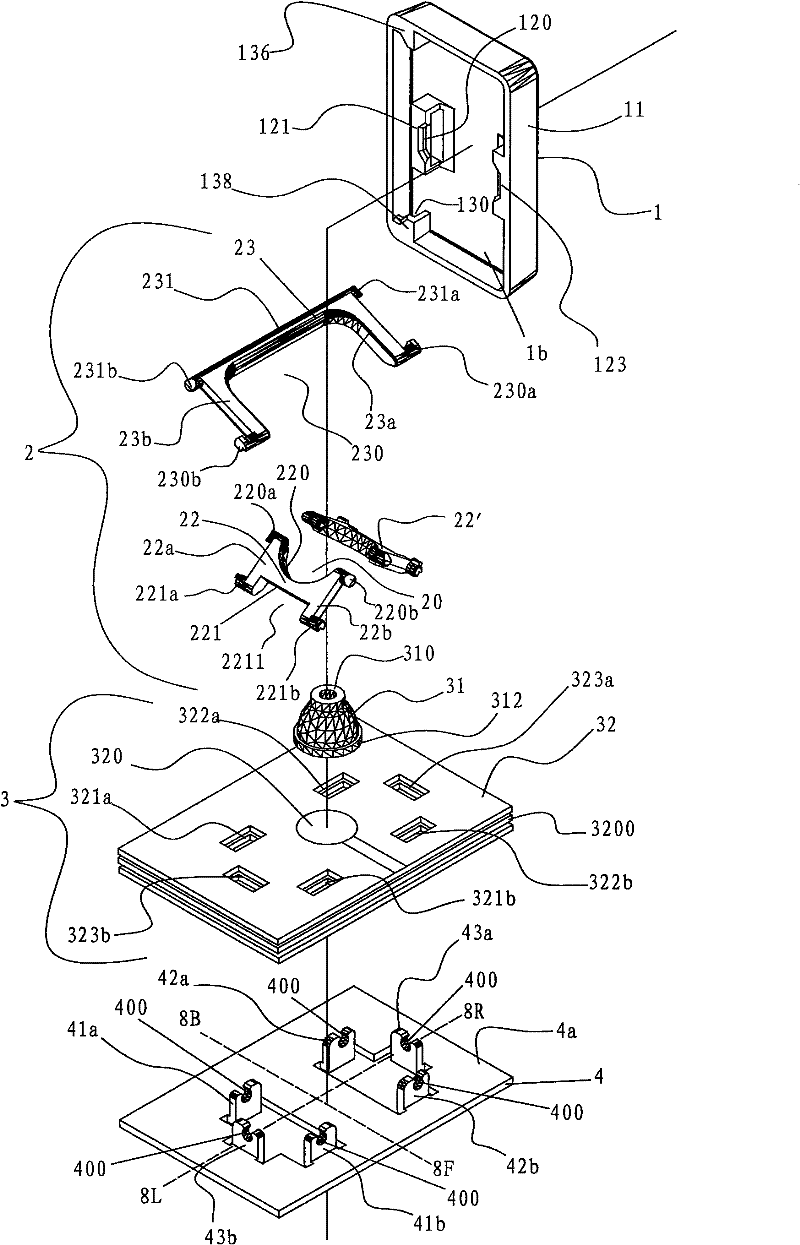

[0051] Keyboard (not shown) of the present invention, as the input device of electronic instrument, is applicable to personal computer, mobile phone, notebook computer and netbook etc., has a plurality of ultra-thin keys, and each key is made of a key lifting switch device, so The keyboard of the present invention is formed after a plurality of key lift switch devices are assembled according to the preset arrangement of the keyboard layout. Similarly, the assembly process of the key lift switch devices is also applicable to the formed keyboard.

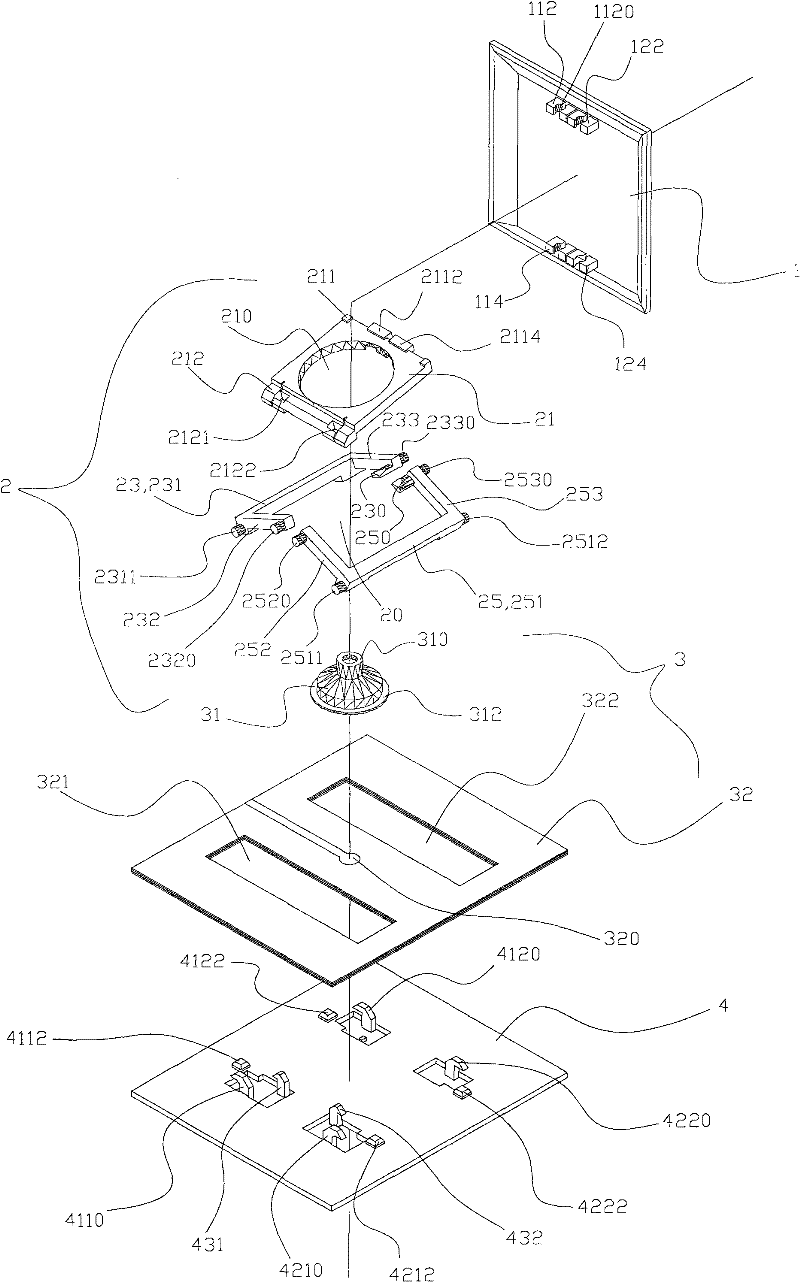

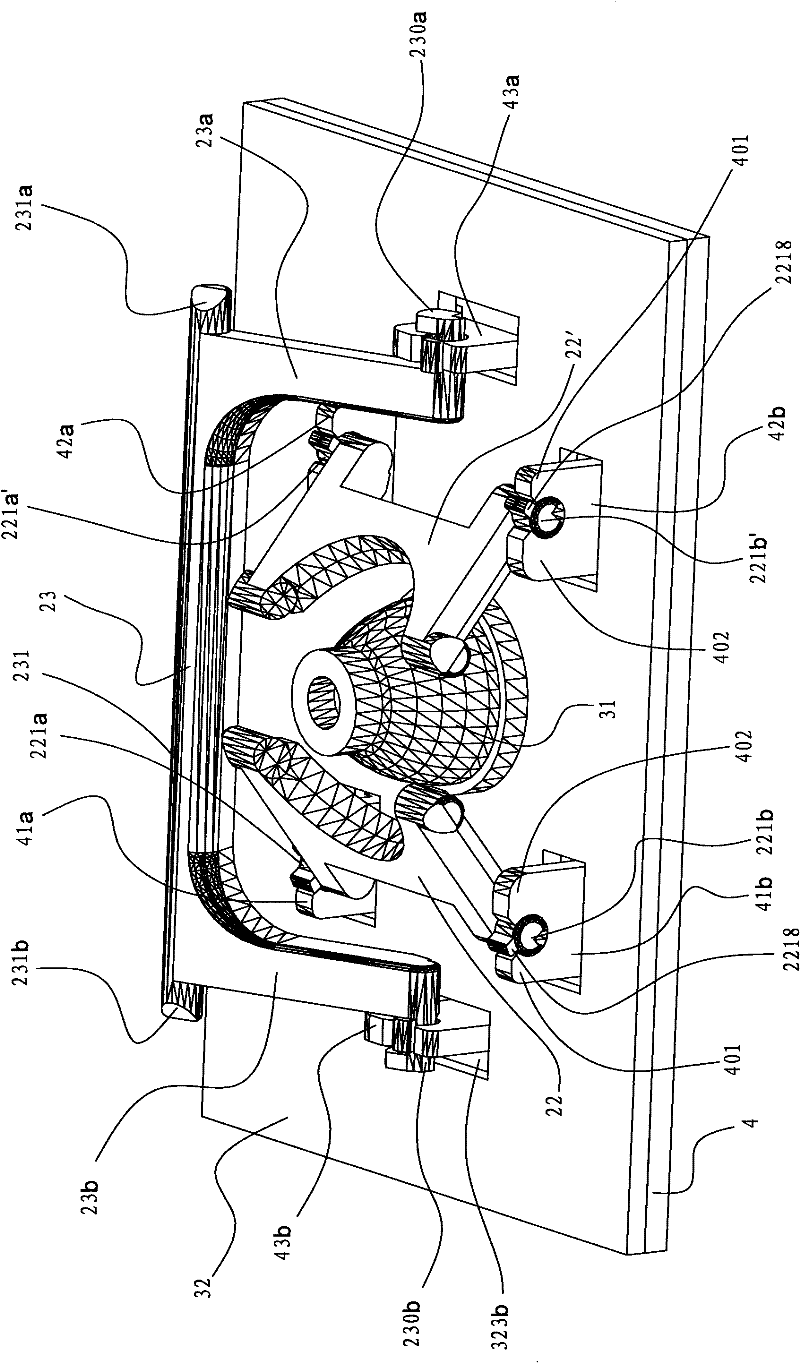

[0052] see figure 2 The keyboard of the present invention includes a support plate 4, a switch mechanism 3, a telescopic assembly 2 and a keycap 1, and the support plate 4 is provided for the switch mechanism 3, the telescopic assembly 2 and the keycap 1 for installation, and the switch mechanism 3 is installed on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com