Electronic mail box system

A mailbox and alarm system technology, applied in the direction of electrical program control, program control in sequence/logic controller, other household appliances, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

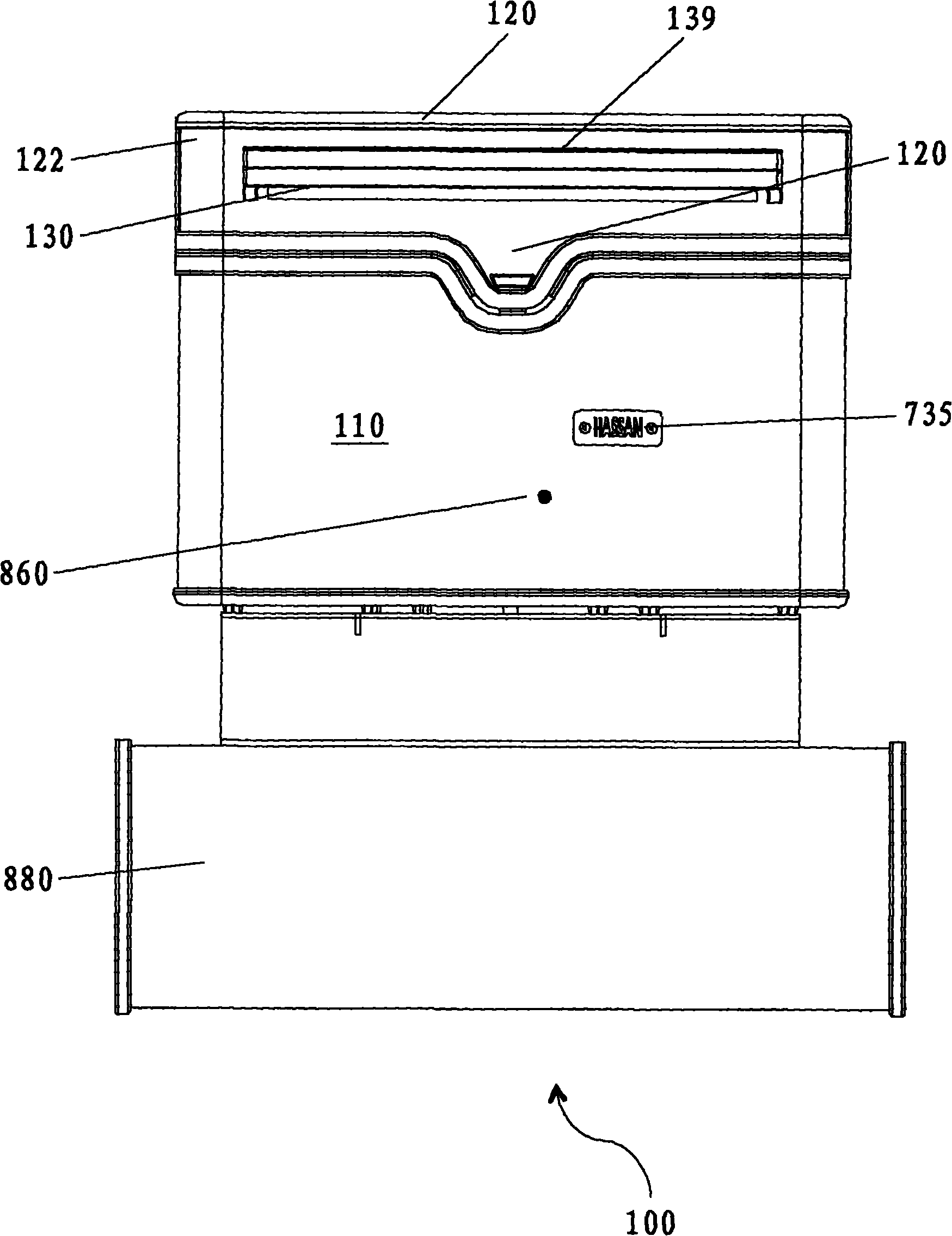

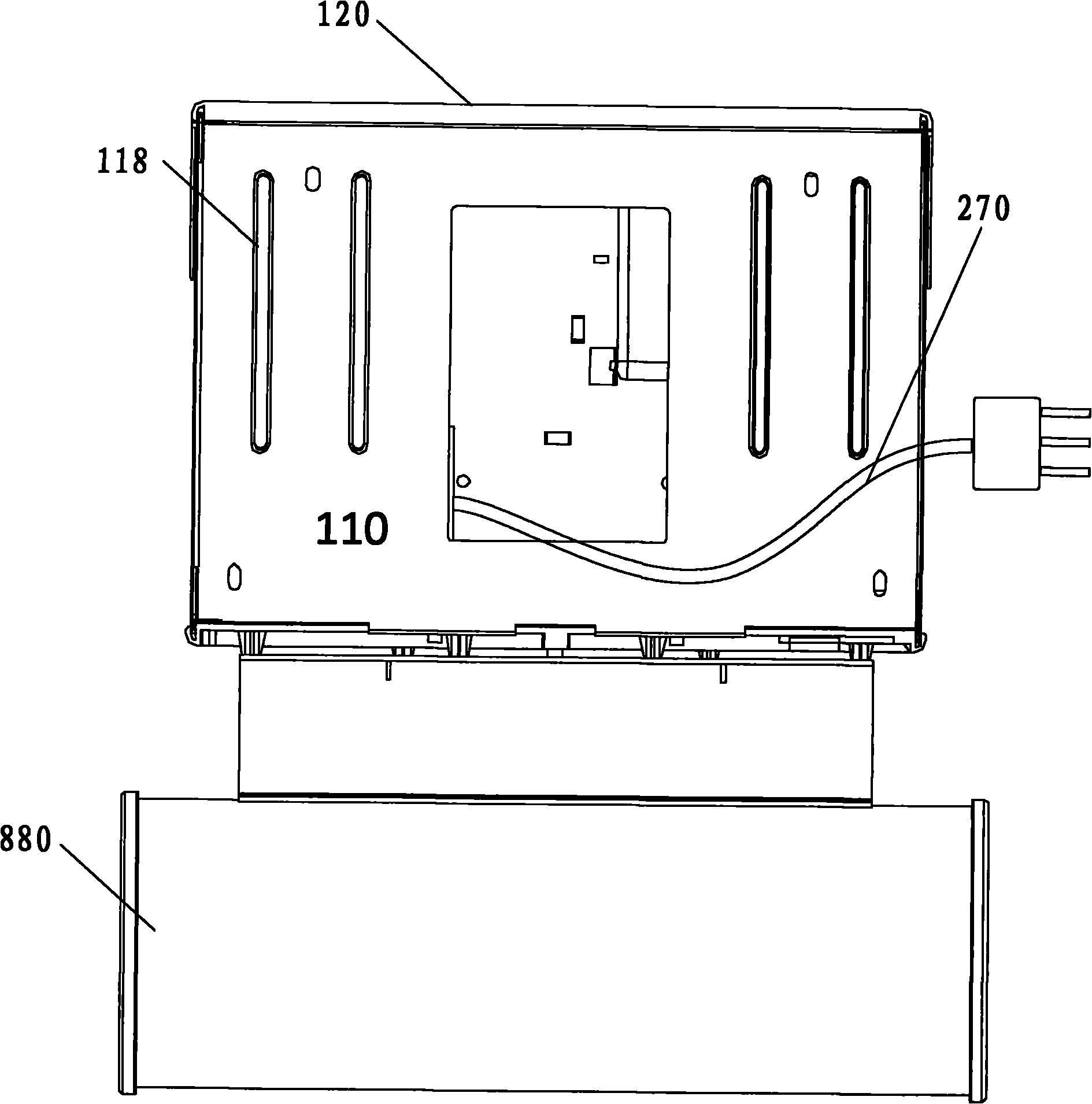

[0036] see now Picture 1-1 7. The present invention is characterized by an electronic mailbox system 100 for providing a secure environment for receiving mail.

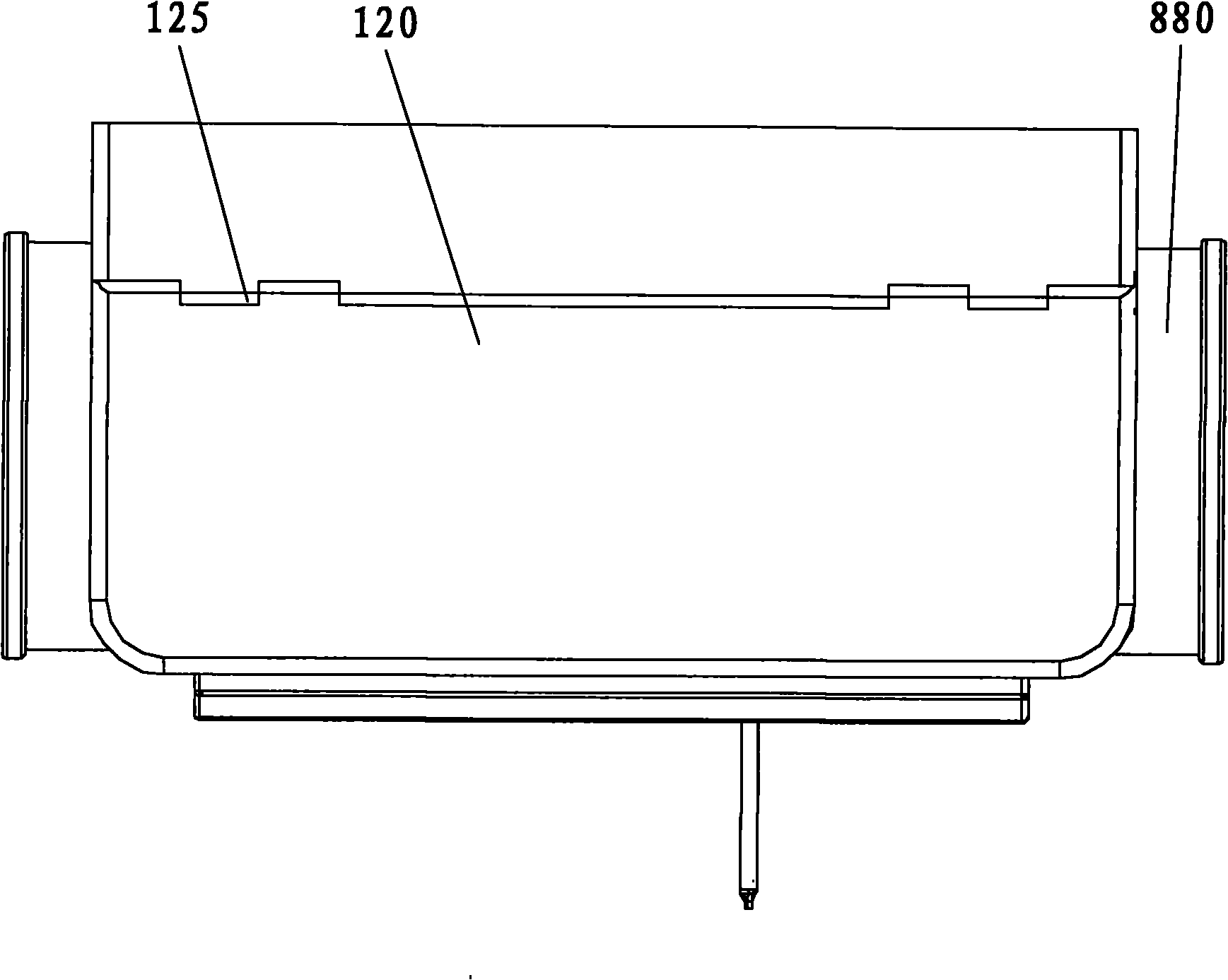

[0037] Such as figure 1 As shown, the electronic letterbox system 100 includes a letterbox housing 110 having a first side, a second side, a front surface, a back surface, a bottom surface, and an interior cavity for receiving letters. A top cover 120 (eg, an "exit door") is pivotally connected to the letterbox housing 110 (eg, back surface, top surface). The top cover 120 (eg, an "exit door") is movable between an open position and a closed position that allow and prevent access to the interior cavity of the letterbox housing 110, respectively.

[0038] In some embodiments, the newspaper holder 880 is disposed on the letterbox housing 110 , such as on a bottom surface (or other portion) of the letterbox housing 110 . A newspaper may be attached to or inserted into the newspaper holder 880 .

[0039]The front su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com