Device for injecting a strand of a paste-like mass into the intermediate space between glass panes of an insulated glass pane

A technology of pasty substances and glass panels, applied in the direction of mixers with rotating stirring devices, transportation and packaging, building construction, etc., can solve the problems of increasing the difficulty of actuating the driving device, and achieve weight saving, volume reduction, and weight reduction Reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

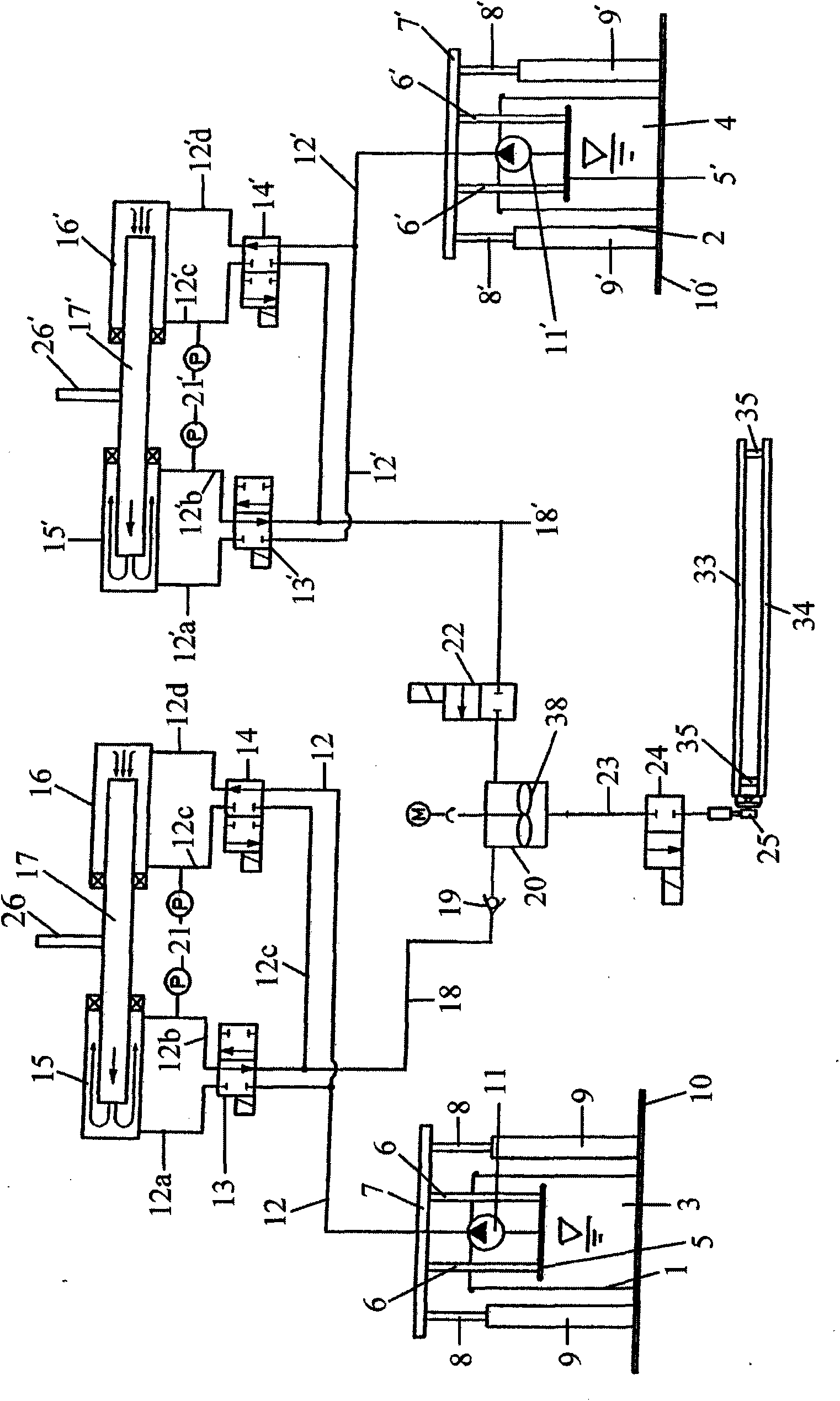

[0054] figure 1A container 1 for a first component 3 of a pasty substance and a container 2 for a second component 4 of the pasty substance are shown. The two containers are cylinders, for example, the lids of which have been removed. The follower plate 5 is arranged on the first component 3 inside the container 1 . Two rods 6 extend vertically upwards from the follower plate 5 to a crossbeam 7, which is not only connected to the two rods 6, but also connected to two piston rods 8 belonging to two hydraulic cylinders 9 respectively, and said The hydraulic cylinder 9 is anchored on a base plate 10 on which the container 1 is also supported. By retracting the piston rod 8 into the hydraulic cylinder 9 , the beam 7 pushes the follower plate 5 onto the reservoir of the component 3 of the pasty substance located in the container 1 . Thus, the component 3 is pushed through an opening in the follower plate 5 and pushed into the pump 11 which is arranged above the follower plate 5 ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap