Device and method for closing a toe at the end of a tubular hosiery article

A knitted sock and tubular technology, which is applied in the field of closed tubular knitted hosiery products, can solve the problems of expensive, occupied, unsatisfactory technical solutions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

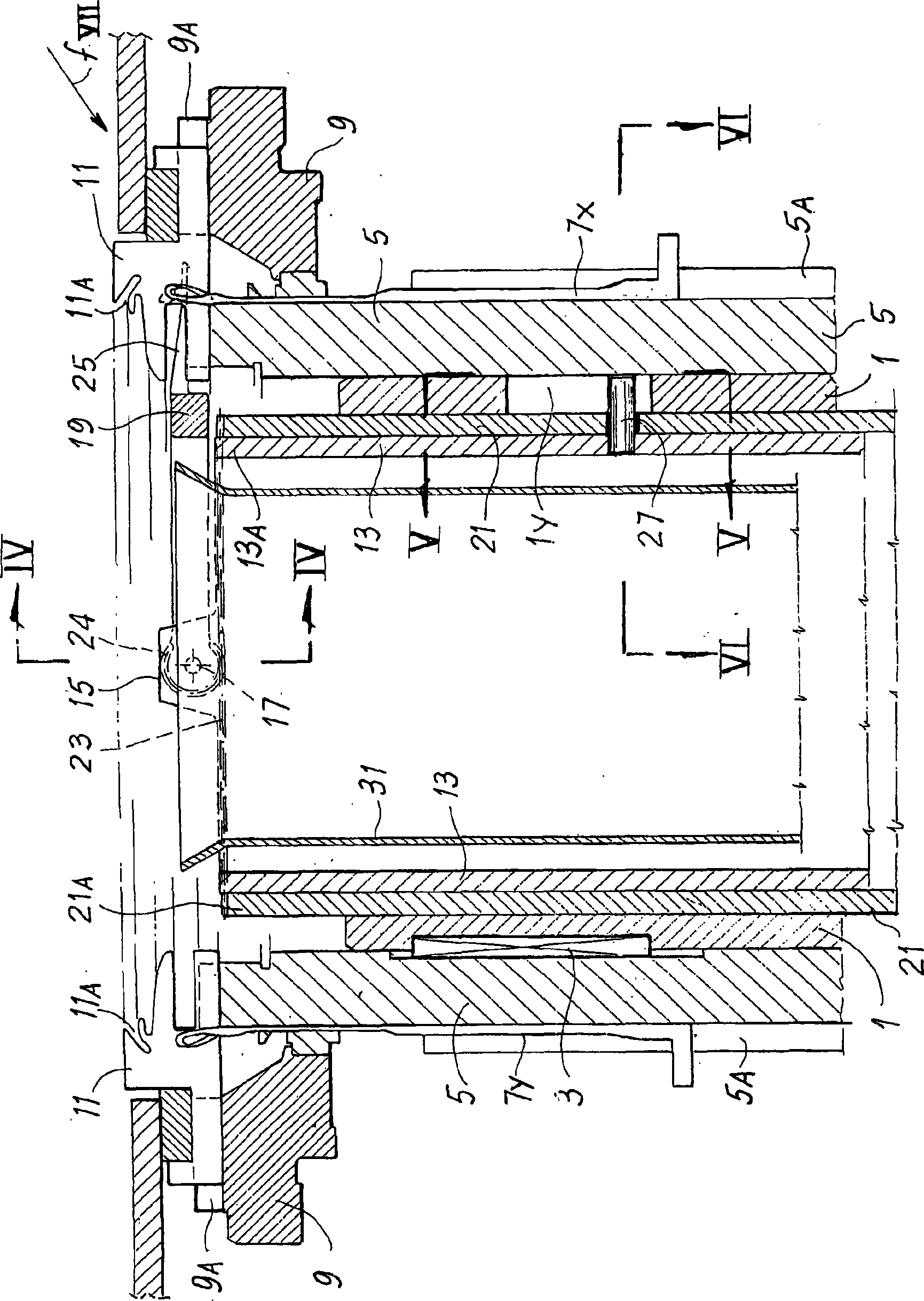

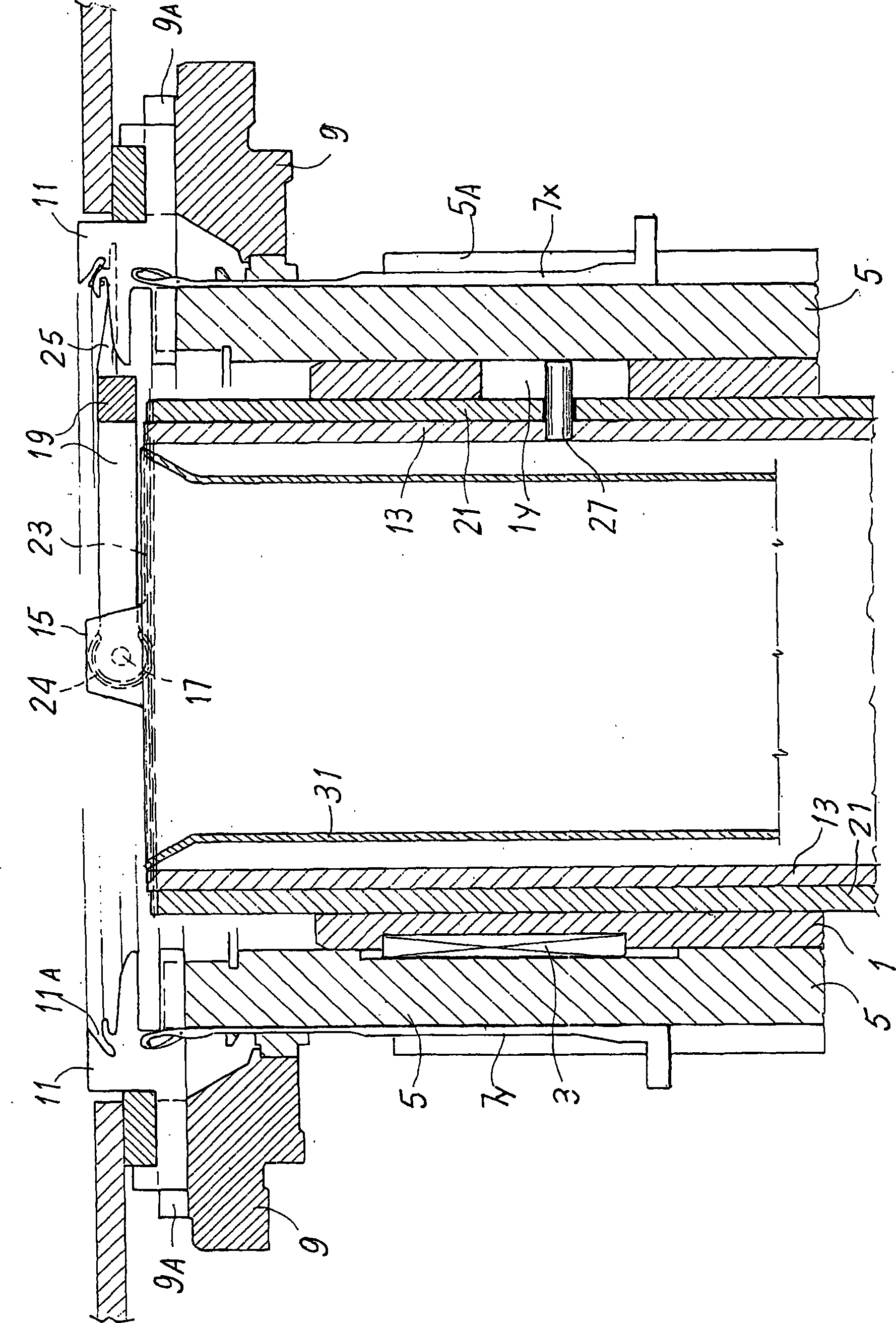

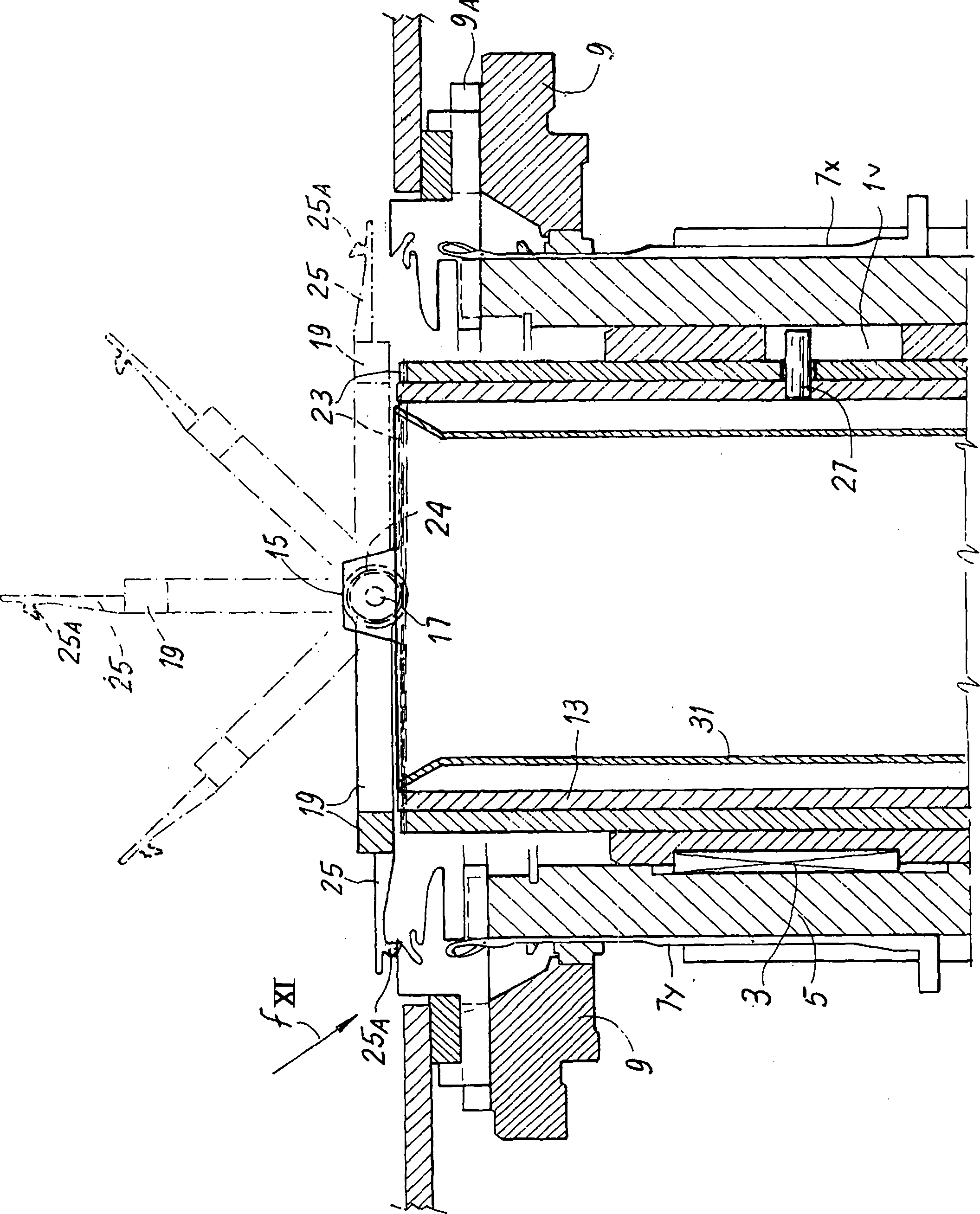

[0024] In the figures, reference 1 denotes a motor cylinder which rotates in order to rotate the cylinder 5 by means of the protrusion 3 or equivalent, with the needles 7X and 7Y in the outer longitudinal passage 5A of the cylinder 5 Swipe in. A conventional sleeve 9 with sliding radial channels 9A for the sinker 11 is integrated above the barrel 5 . This arrangement is conventional.

[0025] Reference 13 denotes a cylinder, which is coaxial with the motor cylinder 1 and the needle cylinder 5 and rotates with them; two diametrically opposite supports 15 are arranged on its upper edge 13A, on which a semicircular The toothed arcs 19 are pivotally connected to the radial pins 17; said toothed arcs 19 can be turned over about 180° so as to be alternately arranged corresponding to the substantially semicircular first needle arcs 7X and the opposite second needle arcs 7Y. In order to control the alternating turning of the tooth arc 19, the cylinder 21 is arranged around the cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com