Sample preparation method for mechanical property test of carbon fiber

A carbon fiber and performance technology, which is applied in the field of sample preparation for carbon fiber mechanical property testing, can solve the problems of cumbersome sample preparation methods, inability to guarantee the accuracy of test results, etc., and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention provides a kind of sample preparation method that is used for carbon fiber mechanical property test, and specific method is as follows:

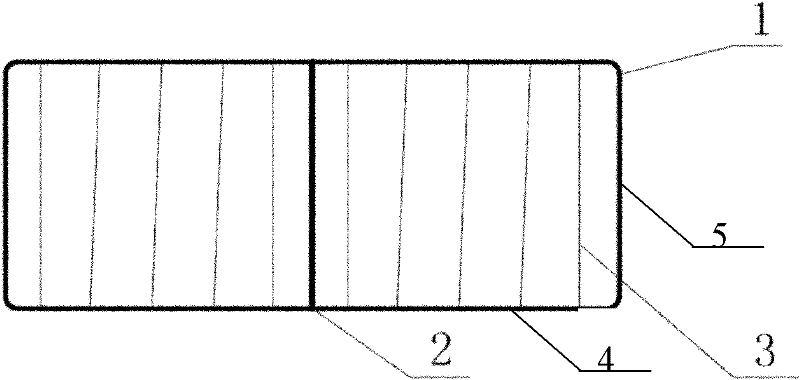

[0023] 1) Wind the carbon fiber to be tested to a rectangular bracket welded by stainless steel tubes with a constant tension. The rectangular bracket is welded by two bottom bars and two ends of support bars, as shown in figure 1 As shown, the two ends of the carbon fiber to be tested need to be fixed on the bottom rod of the bracket with medical adhesive tape; it is required to be wound at least 5 times. The diameter of the stainless steel pipe is generally 3 mm to 10 mm, preferably 5 mm to 8 mm. In order to strengthen the stability between the two support rods, a reinforcing rod 3 parallel to the lower rod is arranged between the two support rods.

[0024] 2) Put the bracket wound with the carbon fiber to be tested into a rectangular plate with a cover welded by a stainless steel plate filled with epoxy resin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com