Sample preparation method for mechanical performance testing of pre-oxidized fibers

A pre-oxidized fiber and mechanical technology, which is applied in the field of sample preparation for testing the mechanical properties of pre-oxidized fibers, can solve the problems of cumbersome sample preparation methods, inability to guarantee the accuracy of test results, etc., and achieve the effect of improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The invention provides a sample preparation method for testing the mechanical properties of pre-oxidized fibers, the specific method is as follows:

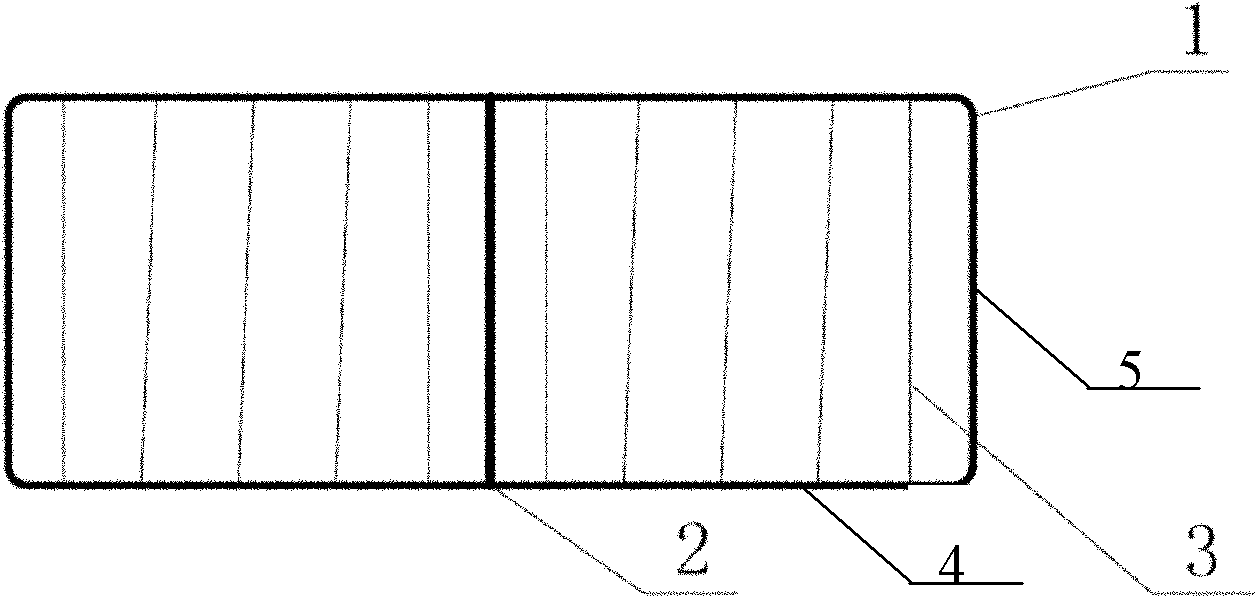

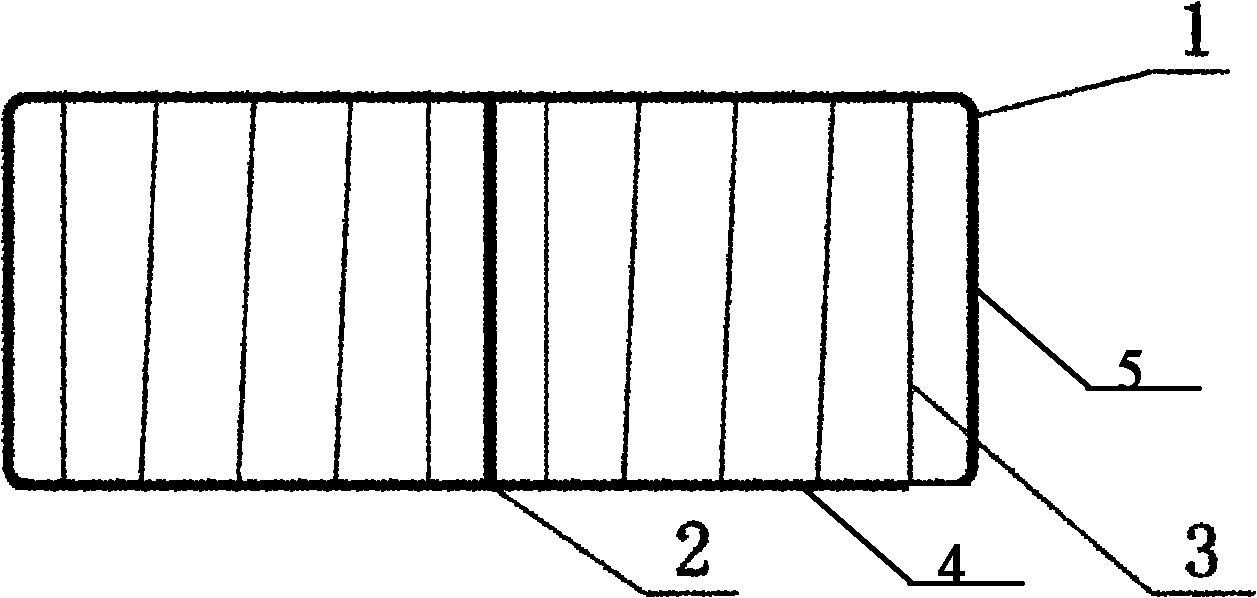

[0023] 1) Wrap the pre-oxidized fiber to be tested on a rectangular bracket welded by stainless steel tubes with a constant tension. The rectangular bracket is welded by two bottom rods and two support rod ends, as shown in figure 1 As shown, the two ends of the pre-oxidized fiber to be tested need to be fixed on the bottom rod of the bracket with medical adhesive tape; it is required to be wound at least 5 times. The diameter of the stainless steel pipe is generally 3 mm to 10 mm, preferably 5 mm to 8 mm. In order to strengthen the stability between the two support rods, a reinforcing rod 3 parallel to the lower rod is arranged between the two support rods.

[0024] 2) Put the bracket wound with the pre-oxidized fiber to be tested into a rectangular plate with a cover welded by a stainless steel plate filled with epoxy r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com