Intensive style circular sorting system and method thereof

A kind of sorting system and intensive technology, applied in the direction of sorting, etc., can solve the problems of increasing investment in equipment, overloading sorting tasks of sorting equipment, and no orders for sorting equipment, so as to improve the sorting speed and solve the problem of Combined sorting efficiency is not high

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

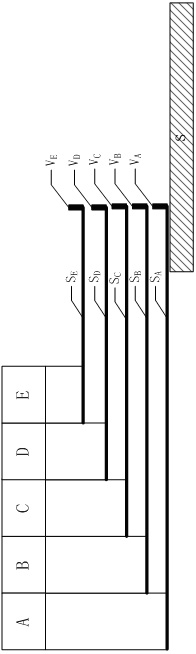

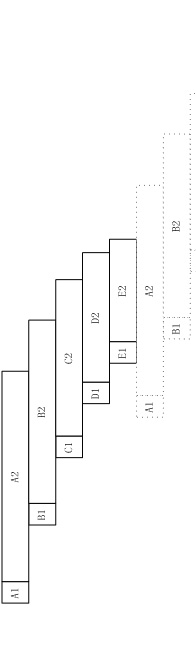

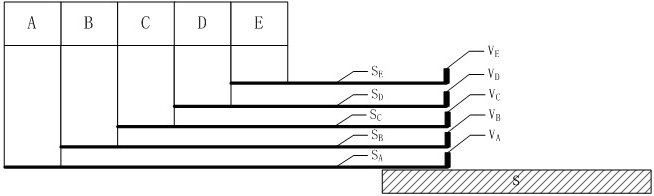

[0024] Such as figure 1 As shown, A~E in the figure represent 5 sets of sorting equipment that can independently accept the command operation of the control center and are not affected by each other; however, in actual application, the number of sub-sorting equipment is not limited Increase or decrease sub-sorting equipment with appropriate scale and product specifications. Each set of sorting equipment corresponds to a set of conveyor belt S A ~S E , as a buffer zone, the lengths of the conveyor belts decrease successively, that is, the large gauge corresponds to the long conveyor belt, and the small gauge corresponds to the short conveyor belt; each conveyor belt end is provided with a valve V A ~V E , to control the passage of cigarettes. At each moment, only one valve is opened, and the cigarettes are collected on the main belt S through the valve.

[0025] The sorting action of each set of sorting equipment is decomposed into two steps. The first step is that the sort...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com