Cooling device for welding device

A cooling device, welding equipment technology, applied in the direction of welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problem of operator inconvenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

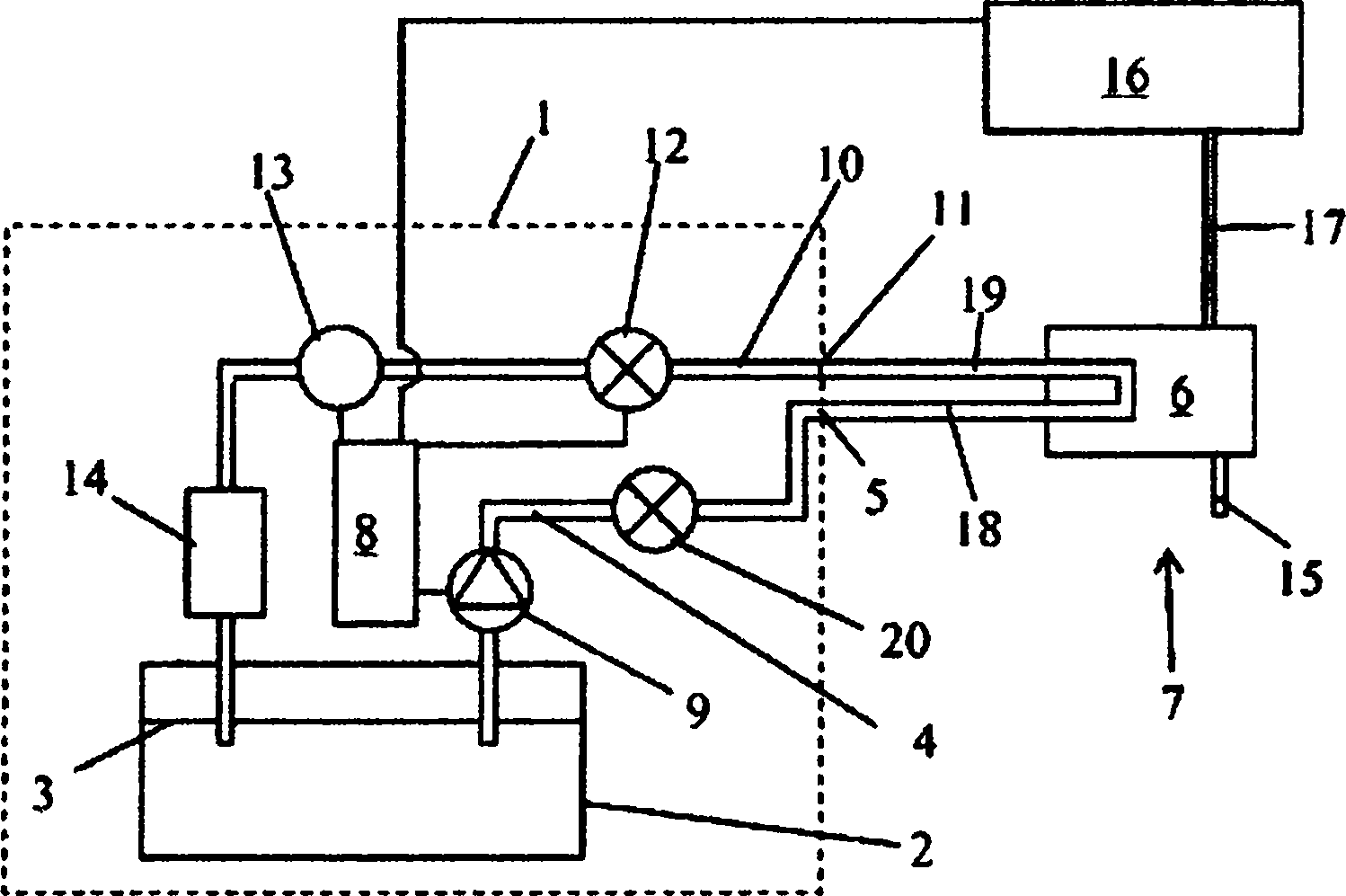

[0021] In the following description of preferred embodiments of the present invention, similar components in different figures will be denoted by the same reference numerals. The drawings are only schematic and are intended to illustrate the invention.

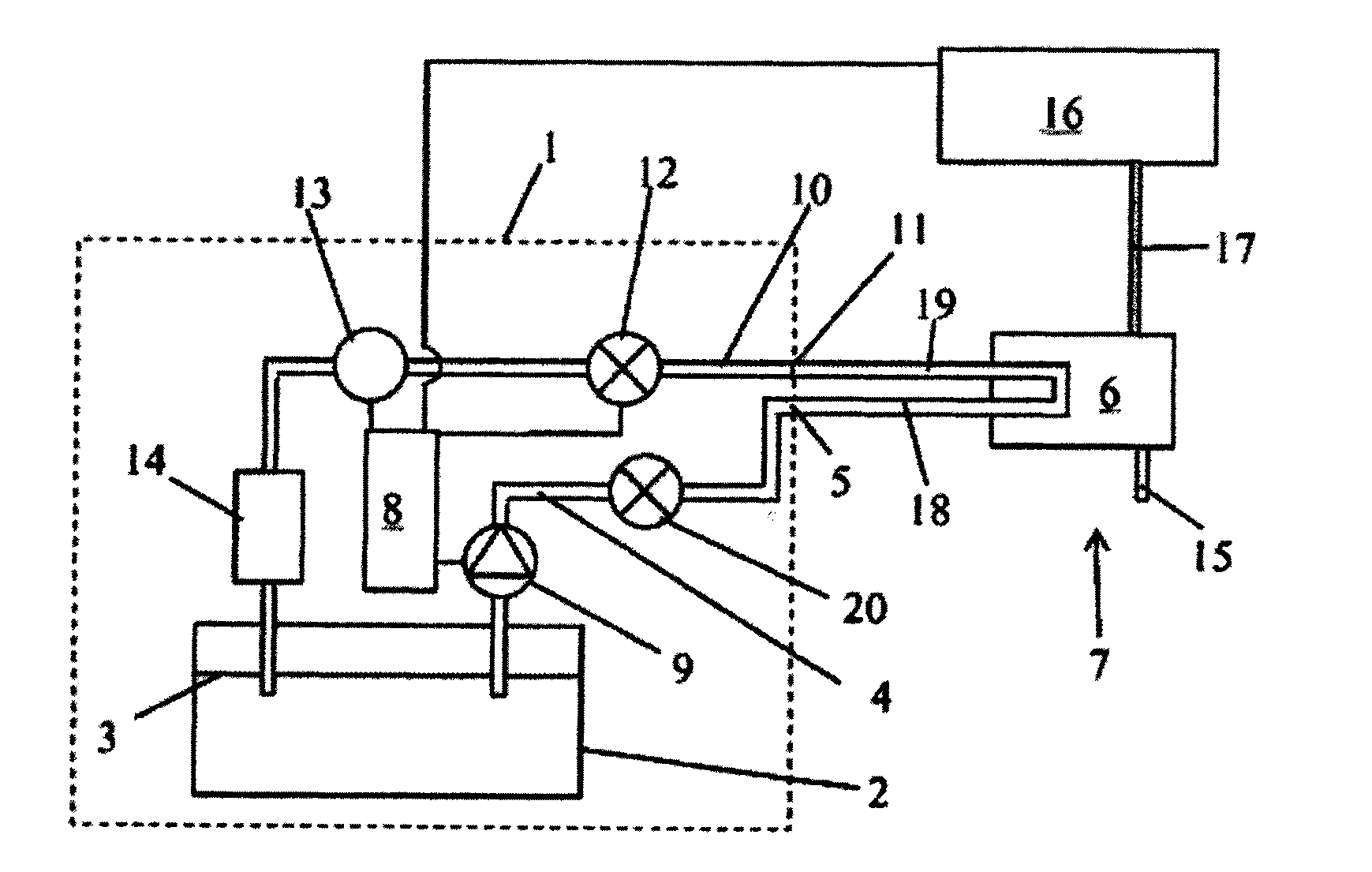

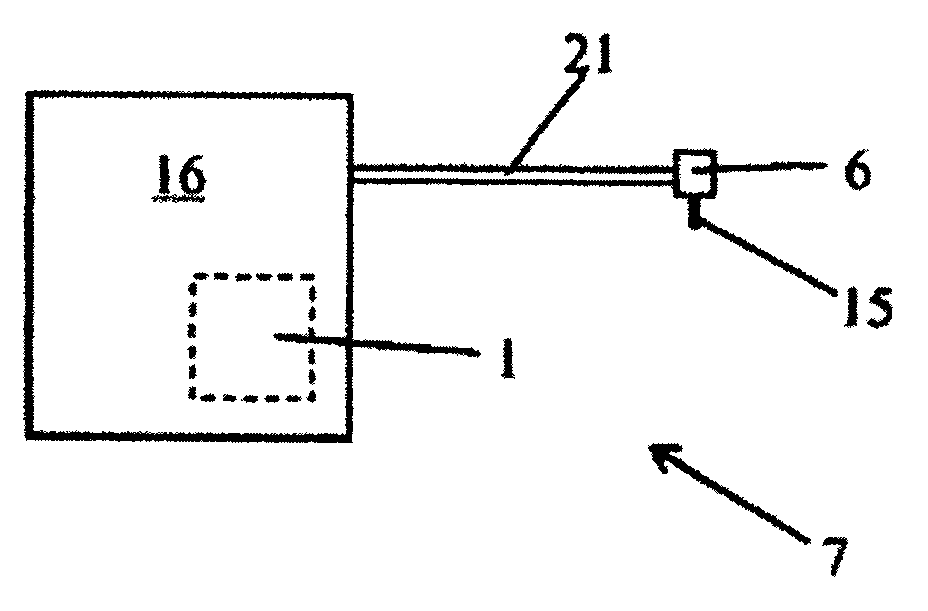

[0022] figure 1 A cooling device 1 according to an embodiment of the invention is schematically shown. Said cooling device 1 is connected to a part in the form of a welding head 6 of a welding device 7 for arc welding, so that the welding head 6 will be liquid cooled. The welding head 6 is arranged for feeding welding wire 15 to the welding area. The welding device comprises a voltage source 16 connected to the welding head by an electrical cable 17 and arranged to supply current to the welding wire 15 . The cooling device 1 comprises a coolant tank 2 containing a coolant having a coolant level 3 . The cooling device 1 also includes a liquid outlet pipe 4 with an outlet 5 for delivering the coolant from the coolant tank 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com