Device and method for suspending linear motor of railway vehicle

A technology for linear motors and rail vehicles, which is applied to electromechanical devices, railway vehicles, and locomotive propulsion methods, can solve problems such as the fracture of fastening bolts, the loosening and rotation of fastening bolts, and the impact on the safety and reliability of linear motors. Installation and disassembly, the effect of simplifying the adjustment process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

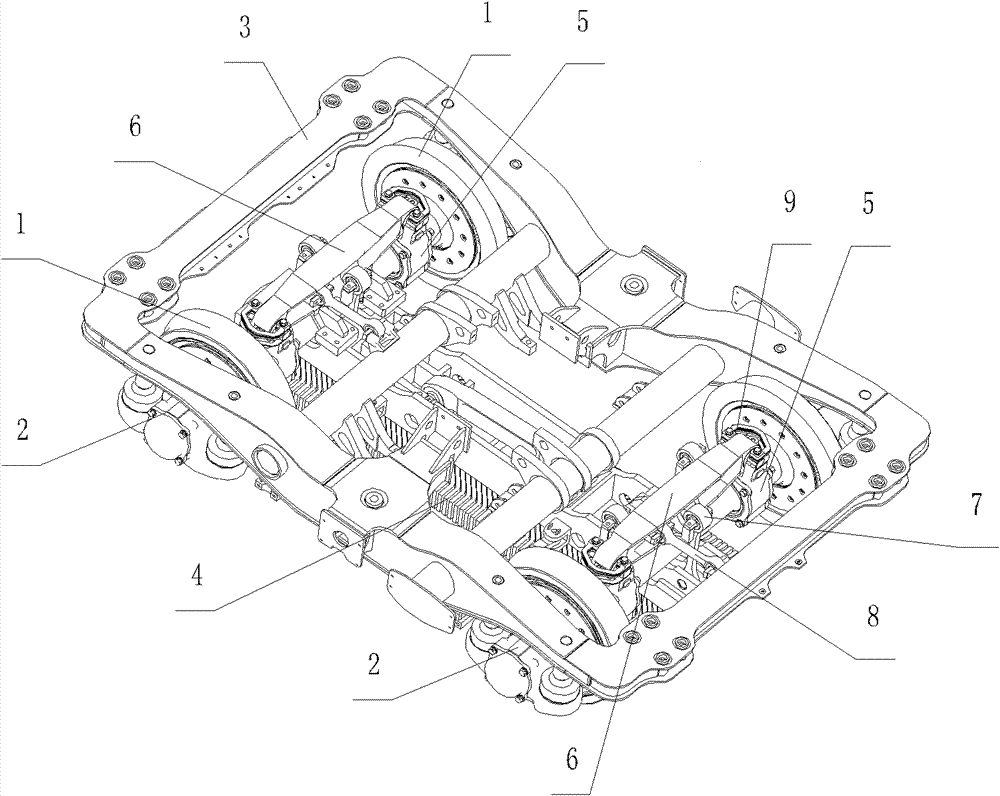

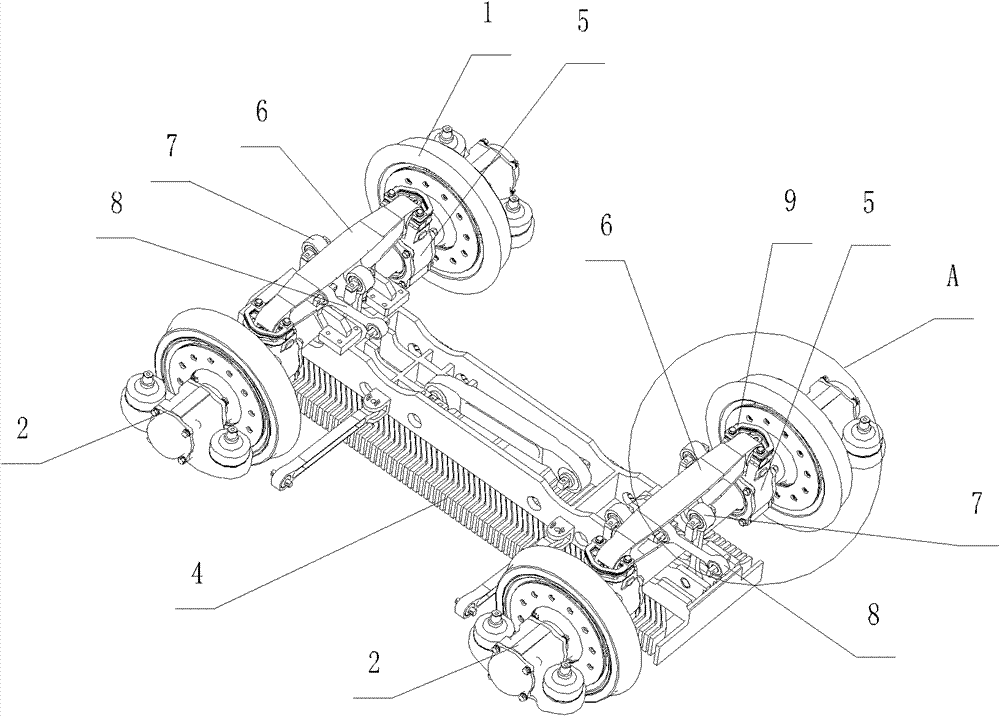

[0047] Example 1, such as figure 1 with figure 2 As shown, the rail vehicle linear motor bogie mainly includes:

[0048] Two sets of wheel sets 1, and the axles 11 of each set of wheel sets 1 are carried on two symmetrically arranged axle boxes 2 through bearings;

[0049] A frame 3, the frame 3 is supported on the axle box body 2 through a series of suspension devices, and the frame 3 is supported on the vehicle body (not shown in the picture) through a second series of suspension devices (not shown in the figure);

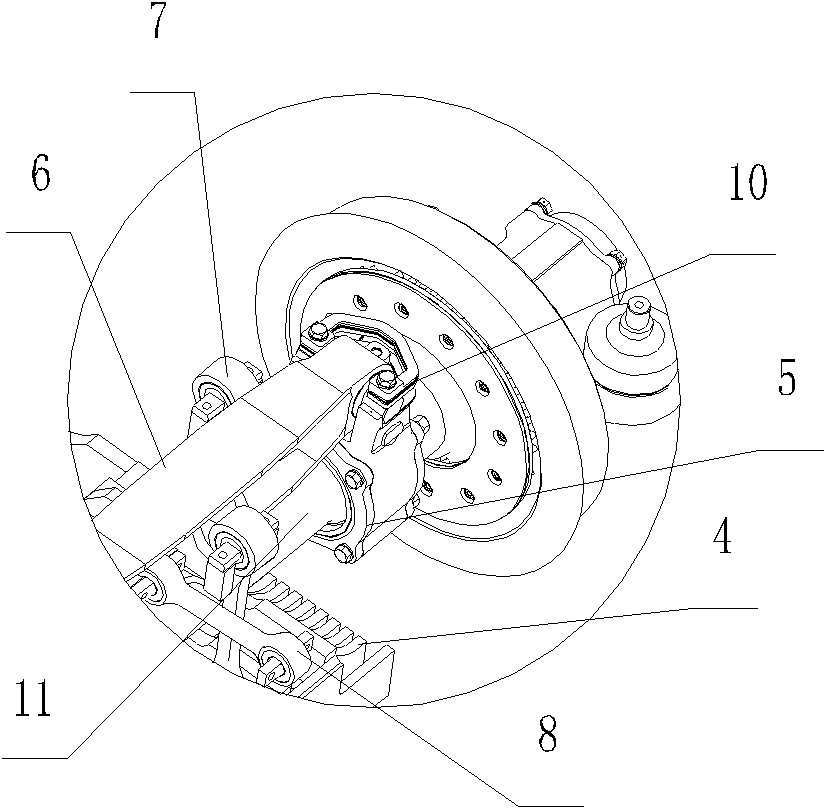

[0050] On the axle 11 of each wheel set 1, two symmetrically arranged support boxes 5 are installed through bearings,

[0051] Several vertical booms 7 suspend the linear motor 4 to each lateral suspension beam 6;

[0052] On the same axle 11, two support boxes 5 are respectively arranged inside the wheel set 1, and two axle boxes 2 are respectively arranged outside the wheel set 1;

[0053] Between each axle 11 and the end of the adjacent frame 3, a balance tie rod 8 for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com