Electric motor assemblies and systems and methods associated with joining wires of electric motor assemblies

A technology of electric motors and wire pairs, which is applied in the direction of electric components, shape/style/structure of winding conductors, electrical components, etc., and can solve problems such as increasing welding robustness, expensive wire positioning tools, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] As needed, detailed examples are disclosed herein. It must be understood that the disclosed embodiments are merely examples of various forms and alternatives. The word "exemplary" is used herein expansively to refer to an embodiment serving as an illustration, sample, model, or model. The figures are not necessarily to scale and some features may be exaggerated or minimized to show details of particular components. In other instances, components, systems, materials, or methods that would be well known by those skilled in the art have not been described in detail so as not to obscure the present invention. Therefore, specific structural and functional details disclosed herein are not to be interpreted as limiting, but merely as a basis for the claims and as a representative basis for teaching one skilled in the art.

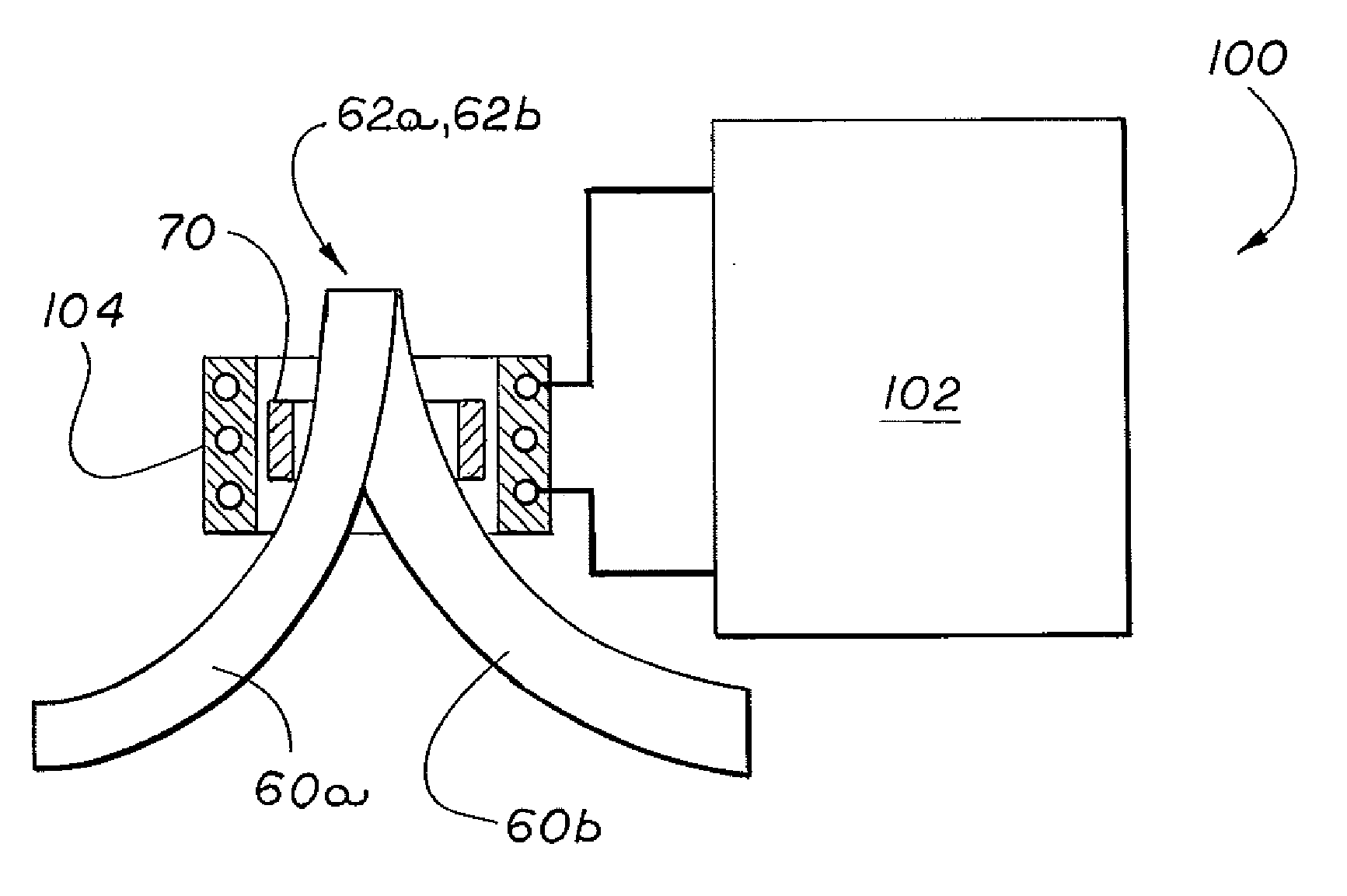

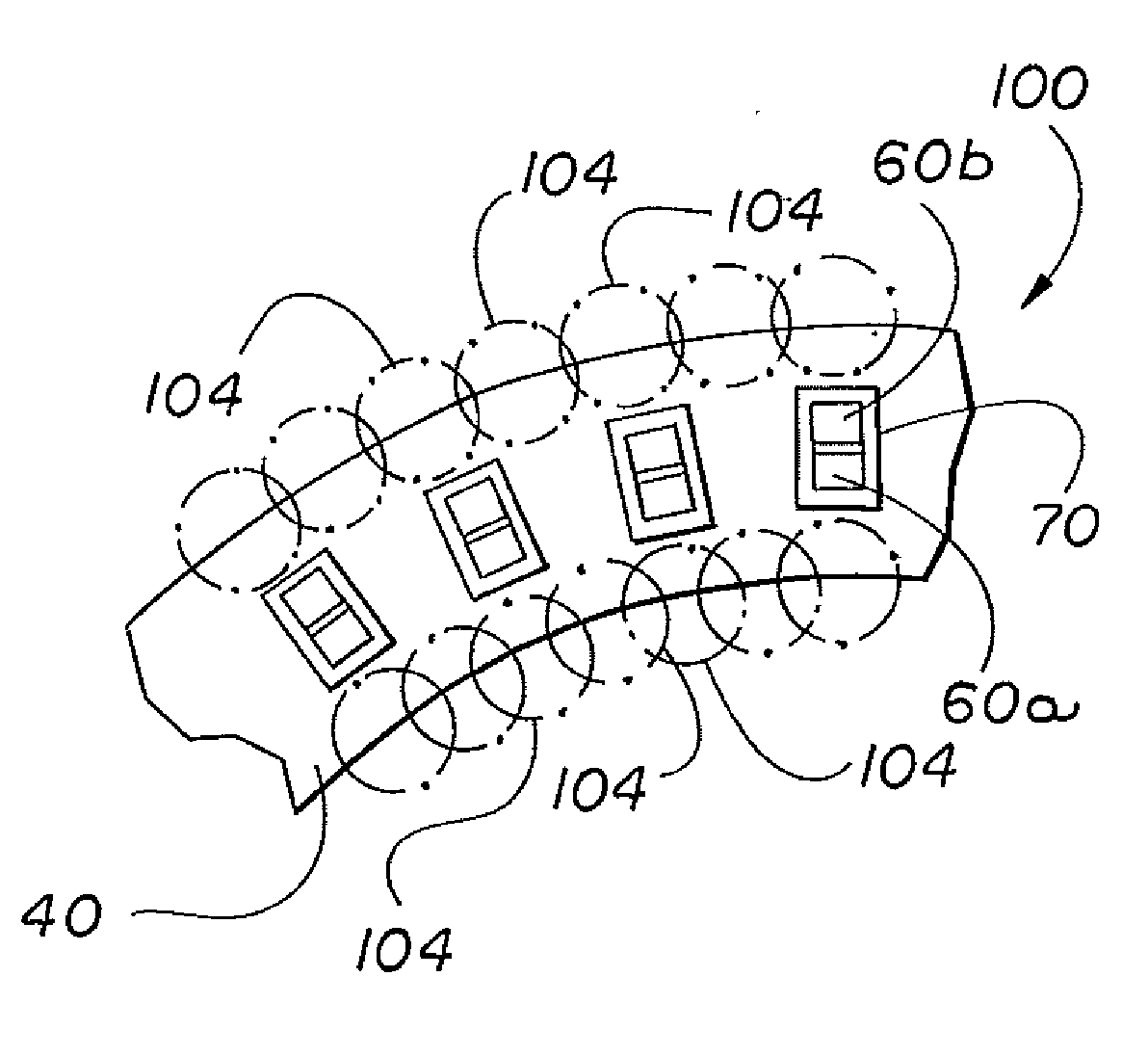

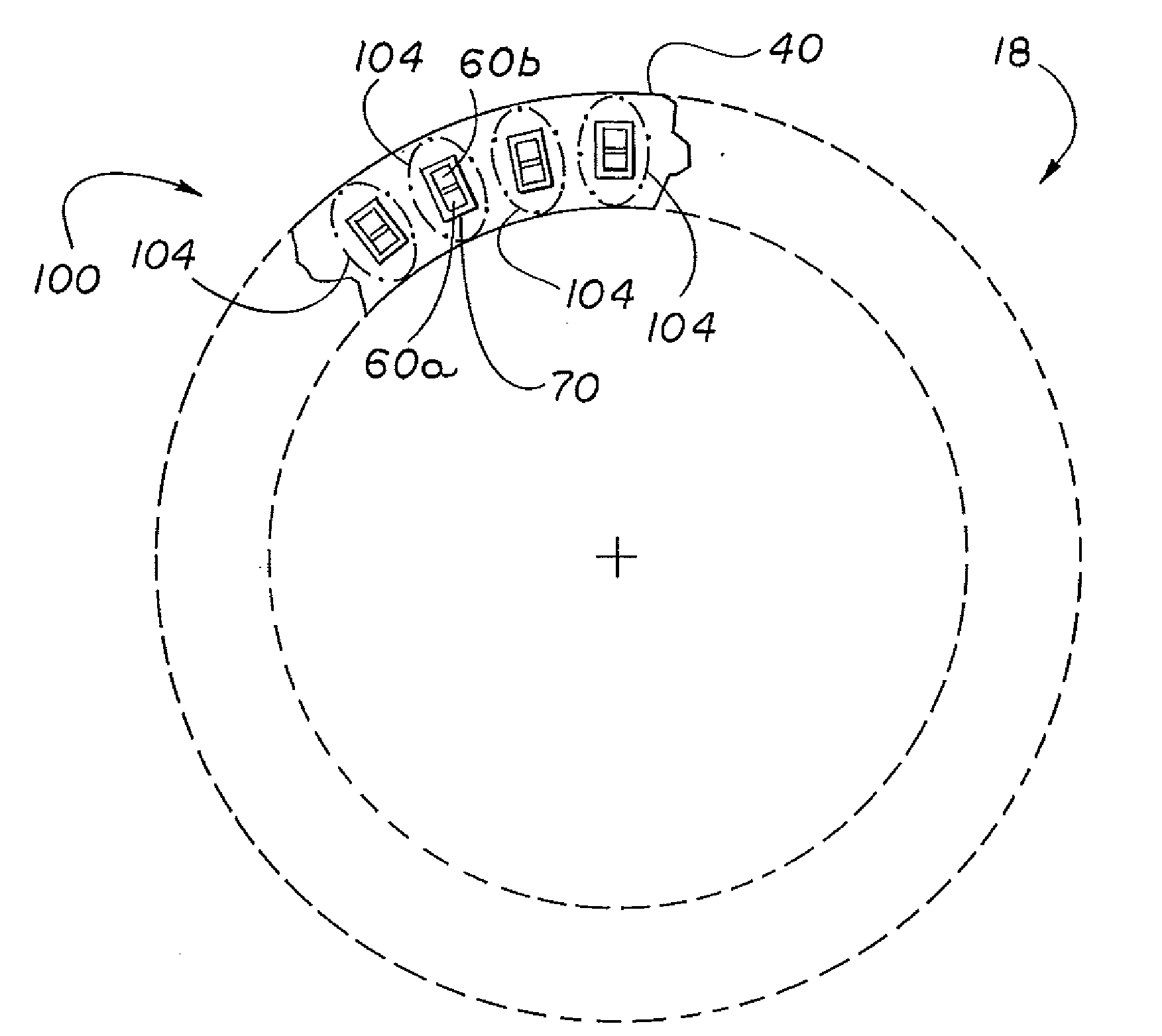

[0050]Embodiments are described herein with respect to the fabrication and assembly of a bar wound electric motor, such as an electric motor including an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com