Continuously variable transmission

A continuously variable transmission, rotating element technology, applied in the direction of transmission, friction transmission, belt/chain/gear, etc., can solve the problem of reducing torque transmission efficiency, and achieve the effect of inhibiting the reduction of transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

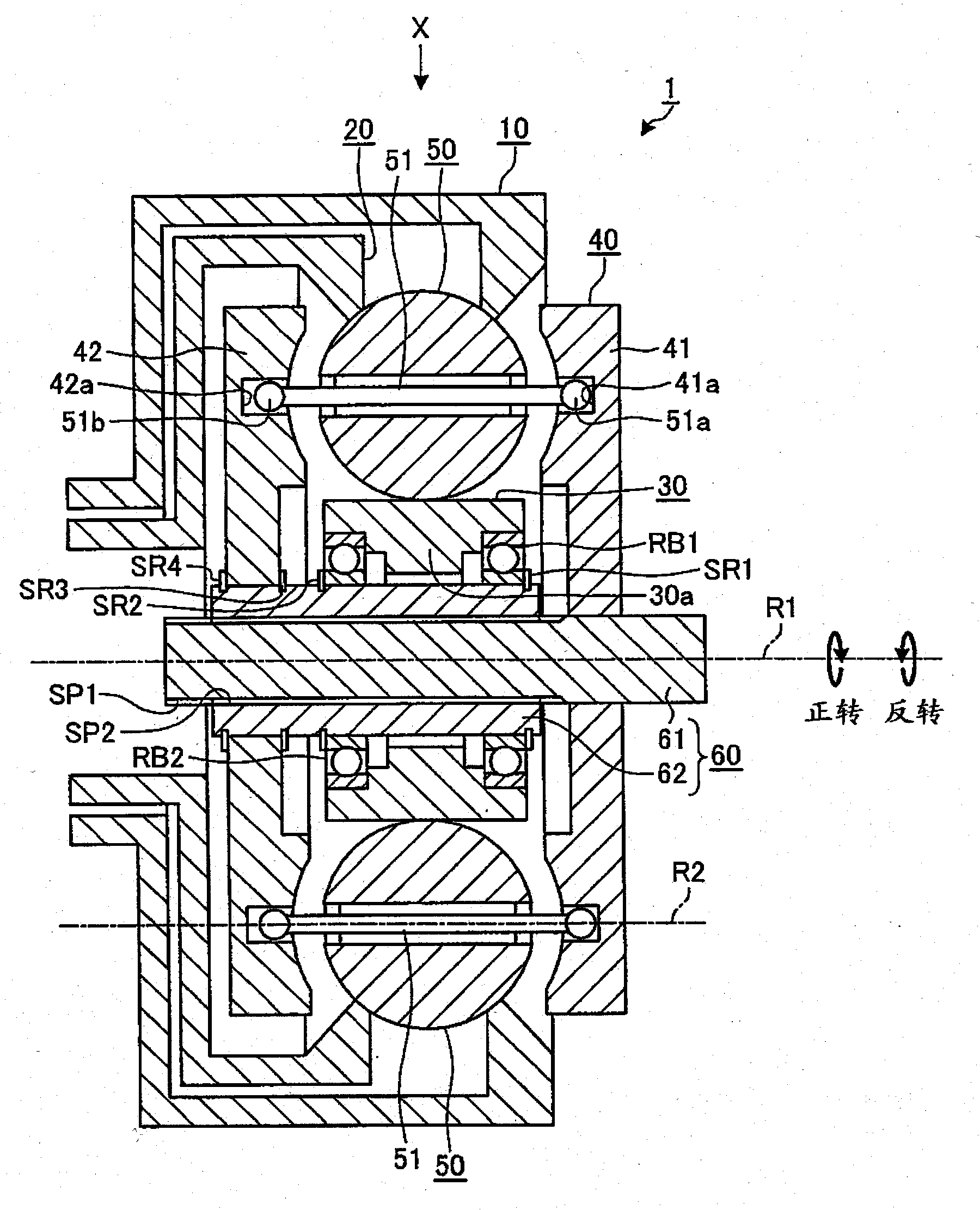

[0027] based on Figure 1 to Figure 7 Embodiments of the continuously variable transmission according to the present invention will be described.

[0028] Initially, use figure 1 An example of the continuously variable transmission of this embodiment will be described. figure 1 Symbol 1 in represents the continuously variable transmission of this embodiment.

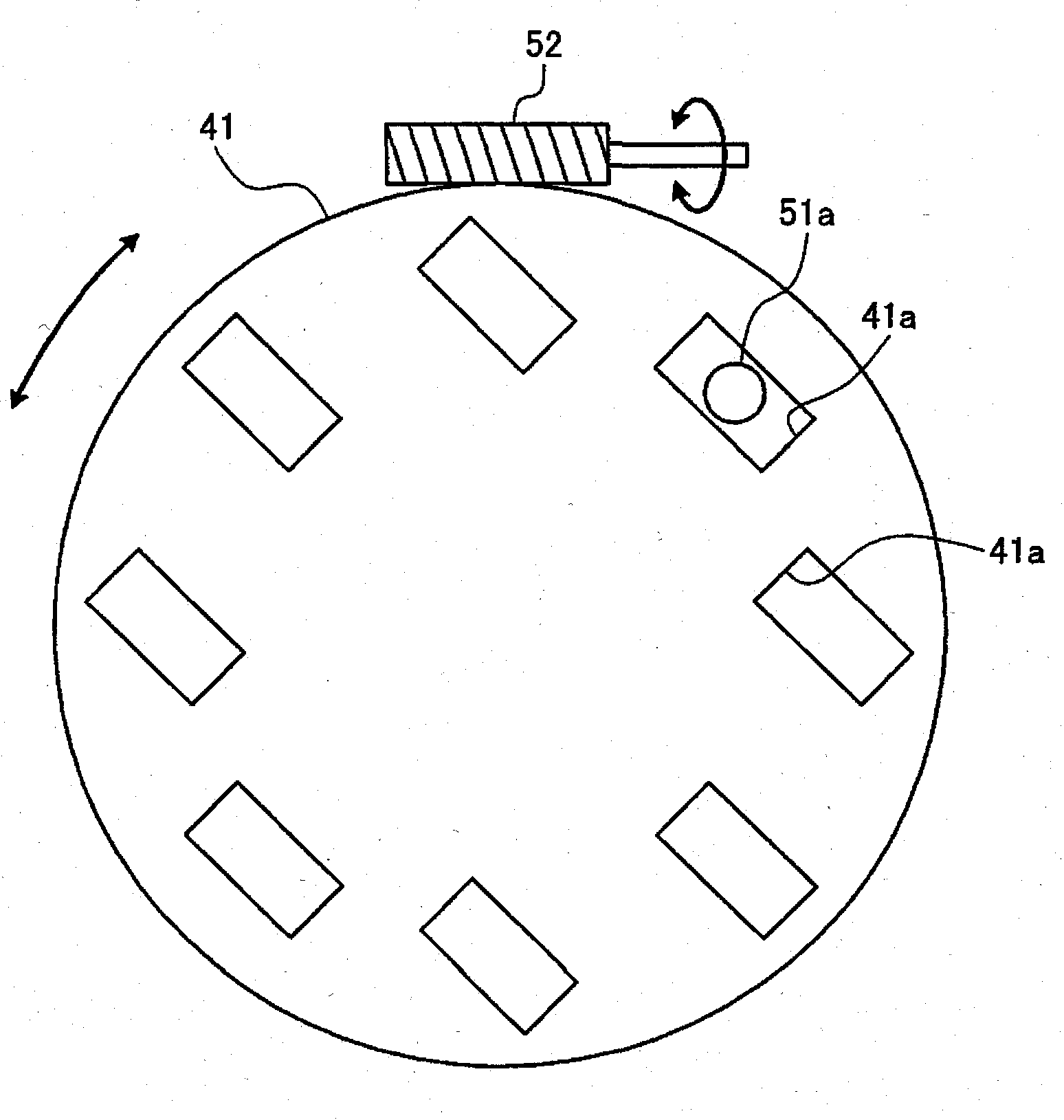

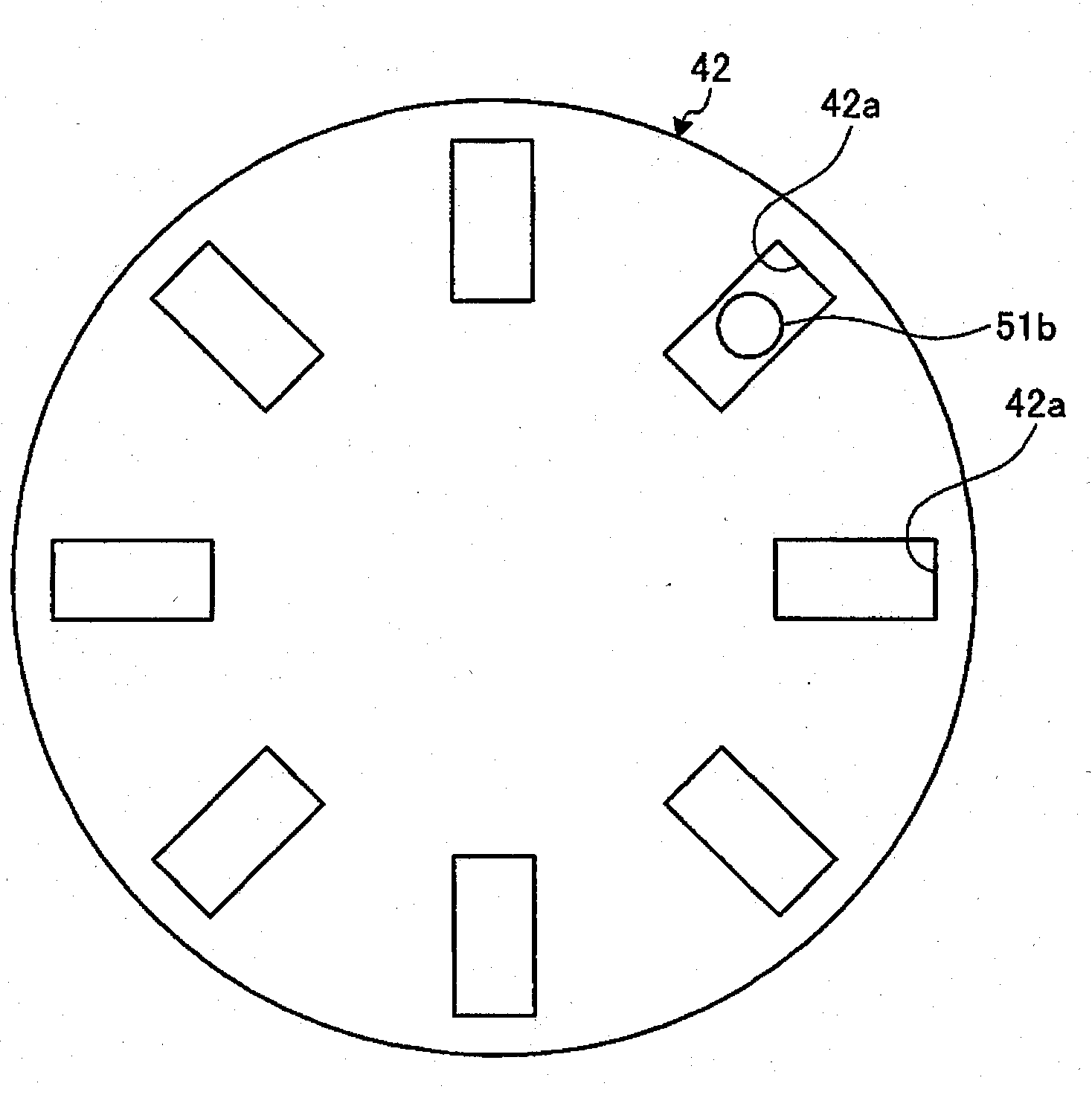

[0029] The continuously variable transmission mechanism constituting the main part of the continuously variable transmission 1 is a so-called traction planetary mechanism. The rotating elements 10, 20, 30, 40 have a common first rotating center axis R1 and can perform relative rotation with each other; a plurality of fifth rotating elements 50, the plurality of fifth rotating elements 50 have a Another second rotational central axis R2 parallel to the central axis R1 at a reference position described later; In this continuously variable transmission 1 , the gear ratio between input and output is changed by tilting th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com