Upper air suction box component of blueprinting machine

A technology of printing machines and suction boxes, applied in optics, instruments, printing equipment, etc., can solve the problems of reducing the speed of printing, inconvenient, waste of human resources, etc., and achieve the effect of increasing the speed of printing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

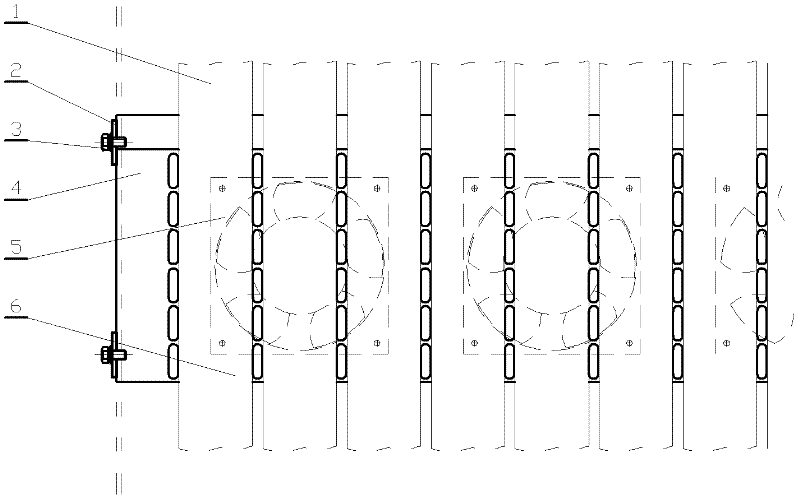

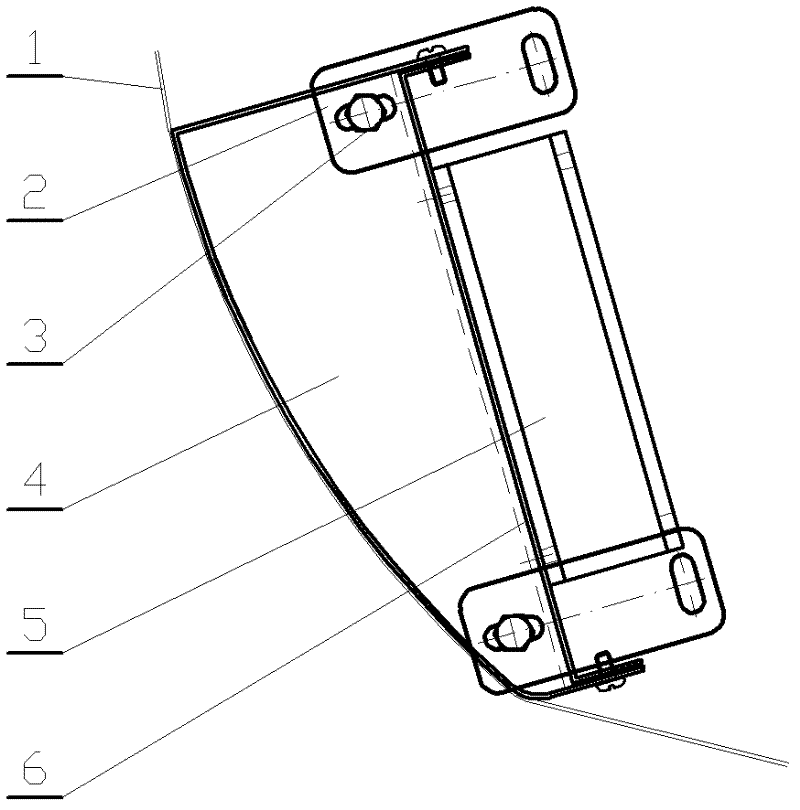

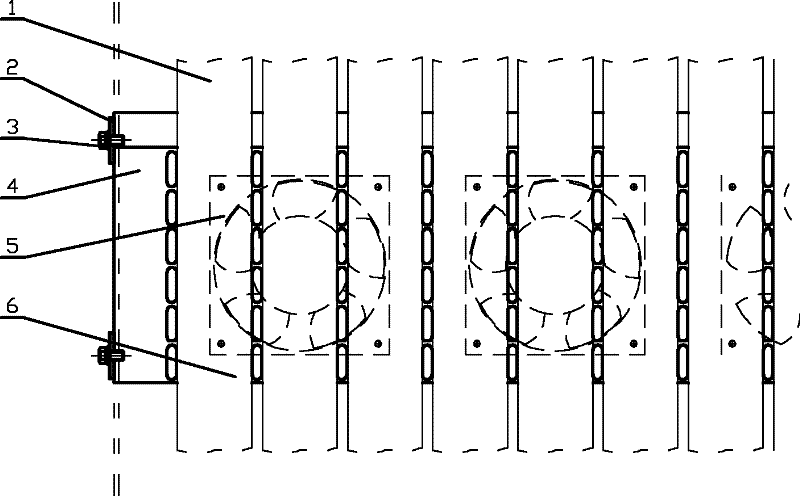

[0011] like Figure 1-2 As shown, it includes a conveyor belt 1, an upper suction box positioning piece 2, a positioning piece fastening screw 3, an upper suction box 4, a suction fan 5, and a suction fan mounting plate 6.

[0012] The upper suction box 4 is positioned on the conveyor belt 1 through the suction box positioning piece 2 and the fastening screw 3, the suction fan mounting plate 6 is installed on the upper suction box 4, and the suction fan 5 is installed on the suction fan mounting plate 6 .

[0013] The relative position of the upper suction box 4 and the conveyor belt 1 is adjusted by the fastening screw 3 and the suction box positioning piece 2 .

[0014] There are two groups of the suction box positioning piece 2 and the fastening screw 3, which are respectively located at the upper and lower ends of the upper suction box 4.

[001...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com